What is PCBA?PCBA meaning = Printed Circuit Board Assembly,also known as finished circuit board, refers to the entire process of PCB empty boards being mounted through SMT or through DIP plugins. PCBA is the motherboard of electronic products, which is the assembly process of PCB and electronic components after all components are soldered and installed on the PCB.

The production process of PCBA mainly involves surface mount technology (SMT) and through-hole technology. Among them, SMT (Surface Mount Technology) mainly uses a mounting device to attach some small components onto the PCB board. The production process includes steps such as PCB board positioning, printing solder paste, placement of SMT machines, reflow soldering furnaces, and finished product inspection. Through hole technology refers to the installation scheme used for electronic components, which first uses the leads on the components to insert into the holes on the printed circuit board (PCBA), and then manually assembles or uses an automatic insertion installation machine to solder to the opposite side of the solder pad.

PCB circuit board assembly is the foundation of internal components in desktop and laptop computers, such as graphics cards, controllers, network interface cards, and expansion cards. Because surface mount technology is more convenient,the main application technology in the current market is surface mount technology.

PCB assembly manufacturing involves multiple steps and complex technologies. The following are the main steps in PCBA manufacturing:

1.PCB design:Use specialized software for PCB design, taking into account factors such as electrical performance, mechanical requirements, and thermal design.

2.PCB manufacturing:Convert the designed PCB diagram into an actual PCB board. This includes etching or printing copper or other conductive materials onto a substrate to form the required circuit pattern.

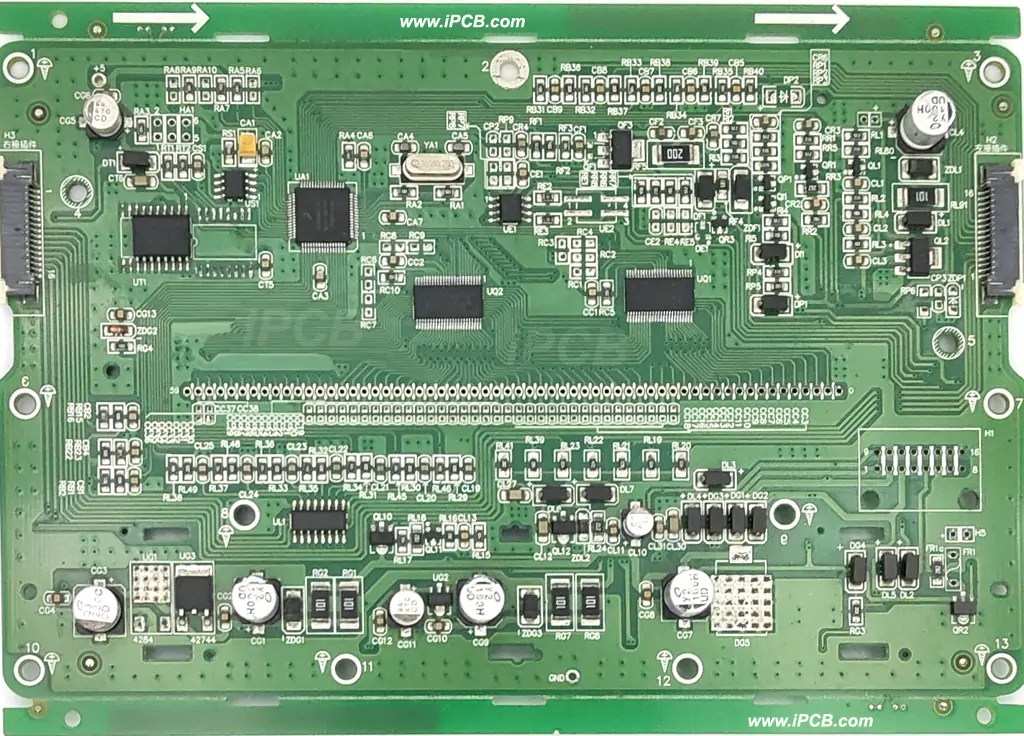

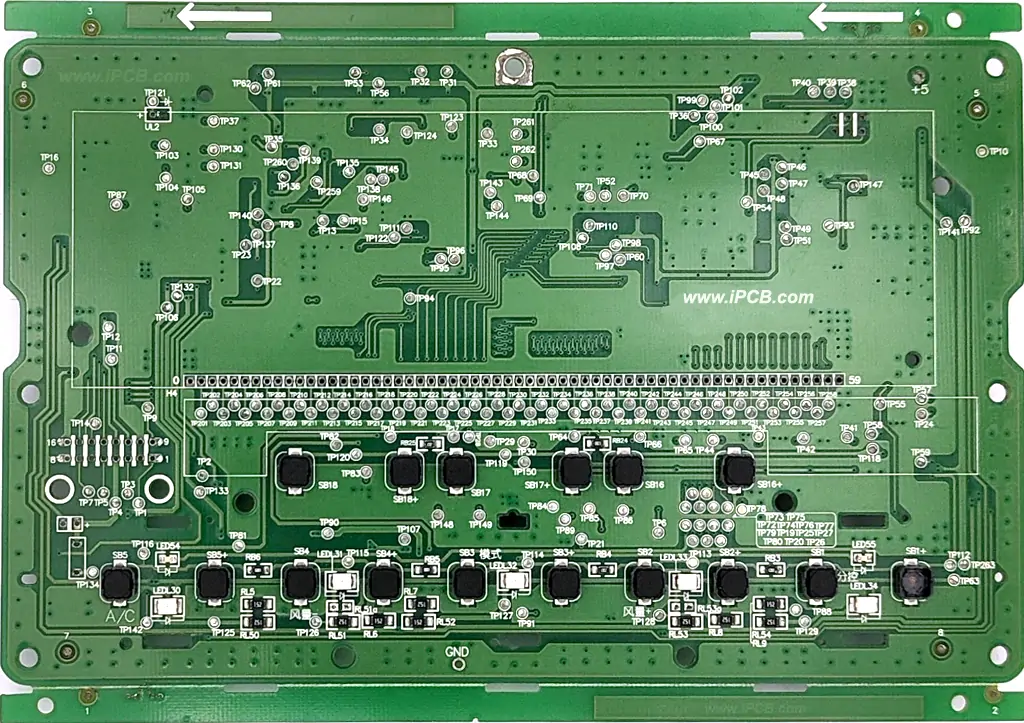

3.PCB assembly:Solder electronic components onto the PCB Circuit board. This can be achieved through SMT or THT.SMT places components on a PCB and then uses hot melt solder to fix the components onto the PCB.THT involves inserting component pins into the holes on the PCB board and soldering them.

4.PCBA testing:Use various testing equipment to test the assembled PCB circuit board assembly and ensure its normal function.

5.PCBA quality inspection:Conduct visual inspection and functional testing on PCB circuit board assembly to ensure it meets specification requirements.

6.Packaging:After completing the quality inspection, PCB board assembly will be packaged for transportation and storage.

The technology and equipment involved in pcb assembly manufacturing are very complex,including PCB design software,PCB manufacturing technology,welding technology,testing equipment,etc.With the advancement of technology, automated and intelligent devices are playing an increasingly important role in PCBA manufacturing.

PCB Assembly

What is the difference between PCB and PCBA?

1.Conceptual differences. A PCB is a printed circuit board, which means a PCB board without electronic component pins and electrical circuits. PCBA is a PCB assembly board based on the design requirements of PCBs, which is completed through the layout, welding, and other process flows of various electronic components.

2.Differences in manufacturing processes. PCB manufacturing typically includes processes such as finished product production, CNC machining, forming, copper coating, drilling, and outer layer finished product production. PCBA manufacturing includes multiple processes, including component procurement, SMT, hole insertion, and post welding process.

3.Application differences. PCB is usually the carrier of the core components of various complex electronic products, such as mobile phones, televisions, home theaters, etc. And PCBA is a finished electronic product, such as computer motherboards, industry control circuit boards, etc.

4 Differences in characteristics. A PCB is a flat circuit board filled with insulation material, which can realize the circuit connection of electronic components and the transmission of mutual signals. On the basis of PCB, PCBA has added the soldering process of components, which can achieve circuit board assembly and practical applications.

So, although PCB and PCB circuit board assembly is very similar in name, they have obvious differences. As the core component carrier in electronic products, PCB plays an important role in electronic design and production processes. PCBA, on the other hand, is an intermediate stage product that involves adding components to a PCB and assembling finished electronic products.

The above iPCB shares what PCBA is, PCBA manufacturing, and PCBA testing related issues. If you need PCB and PCBA Products, please contact us.