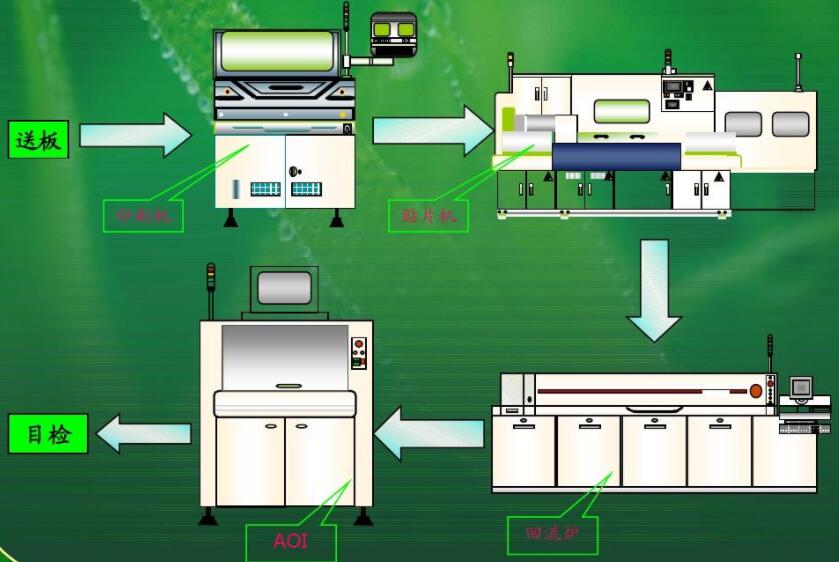

PCBA process is the combination of SMT process and DIP process. According to the requirements of different production technologies, it can be divided into single-side SMT mounting process,single-side DIP insertion process, single-side mixing process,single-side mixing process of mounting and insertion, double-side SMT mounting process and double-side mixing process and so on. PCBA process involves carrier board,printing,mounting,reflow soldering, insertion, wave soldering,testing and quality inspection,etc.For details,please refer to the following flow chart of PCBA process.

Different types of PCB PCBA boards,the process has more different,the following details on the various situations to explain the difference.

1.Single-sided SMT mounting

Add solder paste to the component pads,PCB bare board after the completion of solder paste printing,through the reflow soldering mounting of its related electronic components,and then reflow soldering.

2.Single-sided DIP insertion

The PCB boards which need to be inserted can go through wave soldering after the production line workers insert the electronic components,and then cut the feet and wash the boards after soldering and fixing.But the wave soldering production efficiency is lower.

3.Single-side DIP Mixing

PCB board for solder paste printing,paste electronic components after reflow soldering fixed,quality inspection completed after the DIP insertion, and then wave soldering welding or manual welding,if the through-hole components are less, it is recommended to use manual welding.

4.Mixed single-sided mounting and insertion

Some PCBs are dual-panel, one side of the paste, the other side for insertion.Paste and insert the process with single-sided processing is the same, but the PCB over the reflow soldering and wave soldering need to use fixtures.

5.Double-sided SMT mounting

Some PCB board design engineers to ensure the aesthetics and functionality of the PCB board,will use double-sided mounting pipeline. Which A side of the layout IC components, B side mounted chip components. Make full use of the PCB board space to achieve the minimisation of PCB board area.

6.Double-sided Mixed Packaging

Double-sided mixed assembly has the following two ways, the first pipeline PCBA assembly three times heating, lower efficiency, and the use of red glue process wave soldering welding pass rate is relatively low is not recommended. The second pipeline is suitable for double-sided SMD components more, THT components are few cases, it is recommended to use manual welding. If there are more THT components, wave soldering is recommended.