In the manufacturing process of PCB(printed circuit board), the selection of protective materials directly impacts product quality and production efficiency. Peelable masks and Kapton tape, as two commonly used types of protective and masking materials, play an irreplaceable role in different process steps due to their unique properties.

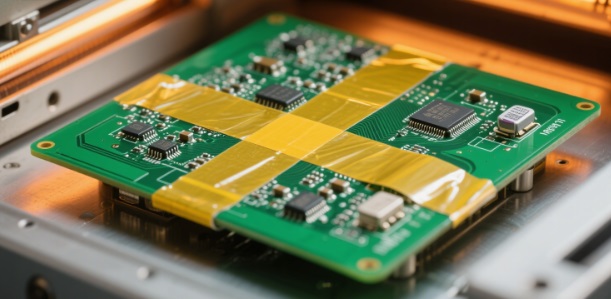

Peelable mask: a "temporary protective layer" for precise masking

A Peelable Mask is a temporary masking material specifically designed for PCB manufacturing. It typically exists in the form of liquid resin or dry film, which is applied to the PCB surface through coating, exposure and development, or direct bonding. After completing a specific process, it can be completely peeled off without leaving any residual adhesive.

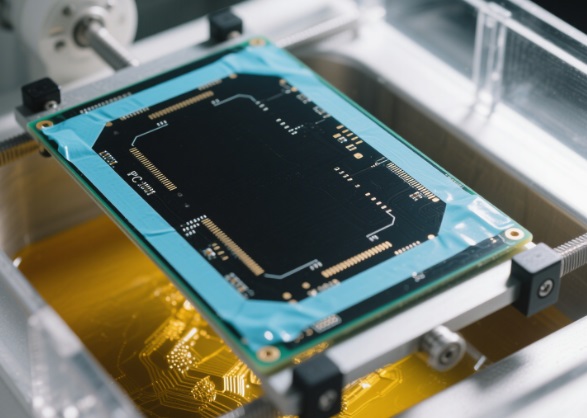

Kapton tape in PCB sandblasting process

Main features:

1. High precision: Liquid strippable masks can achieve micron-level line masking through photolithography, suitable for local protection of high-density circuit boards; dry thin film masks have uniform thickness control, suitable for large-area masking.

2. Chemical resistance: It can withstand the corrosion of chemical reagents such as etching solutions, plating solutions, and cleaning agents, and remains stable in acidic or alkaline environments, ensuring that the masked areas are not damaged.

3. Easy peelability: No adhesive residue remains after peeling, reducing the burden on subsequent cleaning processes, making it especially suitable for mass production of precision PCBs.

Application Scenario:

1. Selective electroplating: When gold or nickel plating is applied to specific areas of a PCB (such as gold fingers or connector solder points), a removable mask is used to shield areas that do not require electroplating, ensuring that the plating is only deposited on the intended locations.

2. Chemical etching protection: Mask the areas of circuits or pads that need to be retained to prevent erosion from etching solution, especially for the protection of complex and irregular shapes.

3. Surface treatment masking: During surface treatment processes such as HASL (Hasl And Spray Tin) and immersion gold, it protects the edges or non-functional areas of the PCB from contamination.

Kapton Tape: The "Tough Guardian" in High-Temperature Environments

Kapton tape is made of polyimide film coated with high-temperature pressure-sensitive adhesive. Due to its excellent heat resistance and mechanical strength, it has become the preferred masking material for high-temperature processes in PCB manufacturing

Application of strippable mask in immersion gold plating process

Main features:

• Extreme temperature resistance: It can withstand long-term use at temperatures up to 260℃ and short-term exposure to temperatures above 300℃, making it suitable for high-temperature processes such as reflow soldering, wave soldering, and hot air leveling (HASL).

• High mechanical strength: Polyimide film is resistant to tearing and puncturing, making it less prone to damage during cutting and handling in PCB processing, effectively protecting the masking area.

• Electrical insulation: It possesses excellent dielectric properties, which can shield while avoiding the risk of circuit shorting, making it suitable for the manufacture of high-frequency PCBs.

Application scenario:

• High-temperature soldering protection: During reflow soldering or wave soldering, shield connectors, capacitors, and other components on the PCB that are not resistant to high temperatures, or protect the exposed copper foil on the edges of the PCB from solder contamination.

• Sandblasting / Grinding Masking: During the sandblasting or mechanical grinding process for PCB contour processing, it protects the circuit area from mechanical damage.

• Temporary fixation: Due to its high temperature resistance, it can temporarily fix the inner layer board during the PCB lamination process to prevent displacement.

Core differences and selection criteria between the two types of materials

| Comparing dimensions | Peelable mask | Kapton tape |

| form | Liquid resin or dry film | Adhesive film (tape form) |

| Concealing accuracy | High (micrometer level, suitable for complex graphics) | Medium (depends on cutting accuracy, suitable for large areas) |

| Temperature resistance range | General (≤150℃, special models can reach 200℃) | Extremely high (long-term resistance to 260℃) |

| Main applicable processes | Electroplating, etching, and room temperature surface treatment | High-temperature welding, lamination, sandblasting |

| Residue after stripping | No residual glue | Low residue (high-quality product), requires minor cleaning |

| cost | Relatively high (especially for liquid lithography type) | Medium (calculated by area) |

Selection principle:

1. If high-precision local masking (such as areas with line spacing < 0.1mm) or chemical process protection is required, strippable masks are preferred;

2. If high-temperature processes (such as welding, laminating) or mechanical processing protection are involved, Kapton tape is a more reliable choice;

3.In mass production, it is necessary to balance process complexity and cost: for simple large-area masking, Kapton tape can be selected, while for complex patterns, strippable masks are preferred.

Peelable masks are being improved towards low viscosity and fast curing to meet the needs of rapid mass production;

Kapton tape, optimized with an ultra-thin substrate (thickness < 25μm) and a low outgassing adhesive layer, meets the stringent requirements of high-end fields such as aerospace.

Whether it's the precise masking of a removable mask or the high-temperature protection of Kapton tape, both together constitute an important part of the "protection system" in PCB manufacturing. Proper selection and application are key to ensuring product yield.