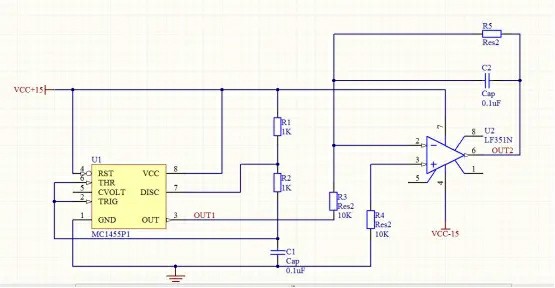

Usually made on insulating materials according to a predetermined design of printed circuit, printed assembly or a combination of both the conductive pattern known as printed circuit. PCB design is a complex process, which needs to be completed through a number of steps. PCB was born in 1936, the United States in 1943, the technology will be used in large quantities in military radios; since the mid-1950s, PCB technology began to be widely adopted. Since the mid-1950s, PCB technology has been widely adopted. At present, PCB has become the “mother of electronic products”, and its application almost penetrates into the electronics industry in all terminal areas, including computers, communications, consumer electronics, industrial control, medical instruments, defense industry, aerospace and aviation and many other fields. printed circuit board schematics.

PCB design process includes the following key steps:

1. Prepare the schematic and network table

This is the foundation of PCB design and needs to be done in a schematic environment. The network table contains the connection relationship between the various components in the circuit, is the basis for PCB layout and wiring.

2. PCB Planning

According to the function and performance requirements of the product, plan the size, shape, number of layers and other parameters of the circuit board. This step determines the overall layout and design direction of the board.

3. Parameter Setting

Including adjacent wire spacing, line width rules, spacing rules, number of layers, over-holes, etc.. These parameters affect the electrical performance and manufacturing process of the circuit board.

4. Import network labeling

Import the network table information in the schematic diagram into the PCB design environment for subsequent layout and wiring work.

5. Layout

According to the function and performance requirements of the circuit, as well as the physical size and electrical characteristics of the components, reasonable arrangement of the location of components on the circuit board. The layout directly affects the signal integrity, thermal management and production cost of the board.

Printed ciruicts boards' schematics diagrams are diagrams that represent the connection principles between devices on a circuit board. The role of the schematic is very important in the program development and other positive research, and the schematic of the quality of the entire project and even life. Extended by the schematic will involve the PCB layout, that is, PCB wiring, of course, this wiring is made based on the schematic, through the analysis of the schematic as well as other conditions of the circuit board limitations, the designer is able to determine the location of the device and the number of layers of the circuit board and so on.

A PCB schematic is a simple two-dimensional circuit design that shows the function and connectivity between different components. A PCB design, on the other hand, is a three-dimensional layout that labels the location of components after ensuring that the circuit is working properly. Therefore, a PCB schematic is the first part of designing a printed circuit board. It is a graphical representation, either in written or data form, that uses agreed symbols to describe circuit connections, and it also suggests the components that will be used and how they will be connected.The PCB schematic is a plan, a blueprint. It describes not where the components will be specifically placed, but the schematic lays out how the PCB will ultimately achieve connectivity and forms a key part of the planning process.

1. Select components such as integrated circuits, transformers, transistors, etc., which are bulky, have many pins and play a major role in the circuit, and then draw from selected reference pins to minimize errors.

2. If the PCB is labeled with component numbers (e.g., VD870, R330, C466, etc.), the drawing should be used since these serial numbers have specific rules, and components with the same Arabic numerals after the letters of the alphabet are the same functional unit. Correctly distinguishing components of the same functional unit is the basis of the drawing layout.

3. If the serial numbers of the components are not marked on the printed circuit board, it is advisable to number them yourself to facilitate analysis and proofreading. When designing printed circuit board components, manufacturers usually lay out components of the same functional unit relative to each other in order to minimize copper-clad wiring. Once a device with a core function is found, other components of the same functional unit can be found as soon as it is located.

4. Correctly distinguish between the ground, power and signal lines of the printed circuit board. In the case of power supply circuits, for example, the negative terminal of the rectifier connected to the secondary of the power transformer is the positive terminal of the power supply, and large-capacity filter capacitors are usually connected between ground and ground, with the capacitor case having polarity markings. The power and ground wires can also be found from the three-terminal regulator pins. When a printed circuit board is factory wired to prevent self-excitation and to resist interference, the ground copper foil is usually set to be the widest (high-frequency circuits usually have a large area of ground copper foil), with the power supply copper foil being the second, and the signal copper being used. Foil is the narrowest. In addition, in electronics with analog and digital circuits, printed circuit boards often have their grounds separated to form separate ground grids that can also be used as a basis for identification and judgment.

5. In order to avoid over-wiring of components. the wiring of circuit diagrams is crisscrossed and interlaced. resulting in a confusing image. and the power and ground lines can be used for a large number of terminal markers and ground symbols. If there are many components, the unit circuits can be drawn individually and then combined.

6. When sketching, it is recommended to use transparent tracing paper and use a multi-color pen to draw ground, power, signal, components, etc. in color. When modifying, gradually deepen the color to make the drawing visually compelling for analyzing the circuit.

7. Skill in the basic components of some unit circuits and classic drawing methods, such as rectifier bridges, voltage regulator circuits and operational amplifiers, digital integrated circuits. These unit circuits are drawn directly into the framework of the circuit diagram, which can improve the drawing efficiency. printed circuit board schematics