With the continuous progress of technology, especially information technology, the technology of printed circuit board production process has grown accordingly to meet the needs of different users. In recent years, communications, transportation and other areas of rapid progress, the need for printed circuit boards has changed a little, high-power printed circuit boards, high-frequency microwave boards need to add. Printed circuit board production companies are optimistic about this increase, but how to do a good job of high-frequency microwave board, the company must practice good basic skills. I personally encountered in the production of problems, a brief description of the high-frequency microwave board production should pay attention to things in the project.

Basic requirements for high frequency microwave circuit boards

1.Substrate material, telecommunication engineers in the preset, has been based on the actual impedance requirements, selected the specified dielectric constant, media thickness, copper foil thickness, because of this, in accepting the order, we must seriously treat the audit check, must be satisfied with the preset requirements.

2.The channel transmission line manufacturing precision requirements of high-frequency signal transmission, the special nature of the printed wire impedance requirements are very strict, that is, the manufacturing precision requirements of the channel transmission line is generally ± 0.02mm (± 0.01mm precision transmission of the transmission line is also very common), the edges of the channel transmission line to be very neat, subtle burrs, notches are not allowed to sprout.

3.Plating requirements of high-frequency microwave board conveyor transmission line of the special nature of the impedance directly affects the quality of the microwave signal conveyor transmission. And the volume of the special nature of the impedance and the thickness of the copper foil has a certain relationship, especially for the hole metallization of the microwave plate, the thickness of the plating not only affects the total thickness of the copper foil, and affects the precision of the line after etching room engraving, because of this, the volume of the thickness of the plating and the average, to be strictly controlled.

4.Mechanical processing requirements first of all, high-frequency microwave board materials and printed circuit boards of epoxy glass cloth material in the machining is very different; secondly, the high-frequency microwave board processing precision than the printed circuit boards require a lot of high, ordinary shape tolerance of ± 0.1mm (high precision ordinary ± 0.05mm or 0 ~ -0.1mm).

5.The special nature of the impedance of the requirements of the special nature of the impedance of the internal material significance of the relevant has been talked about before, it is a high-frequency microwave boards the most basic requirements, can not meet the special nature of the impedance of the requirements of everything is in vain.

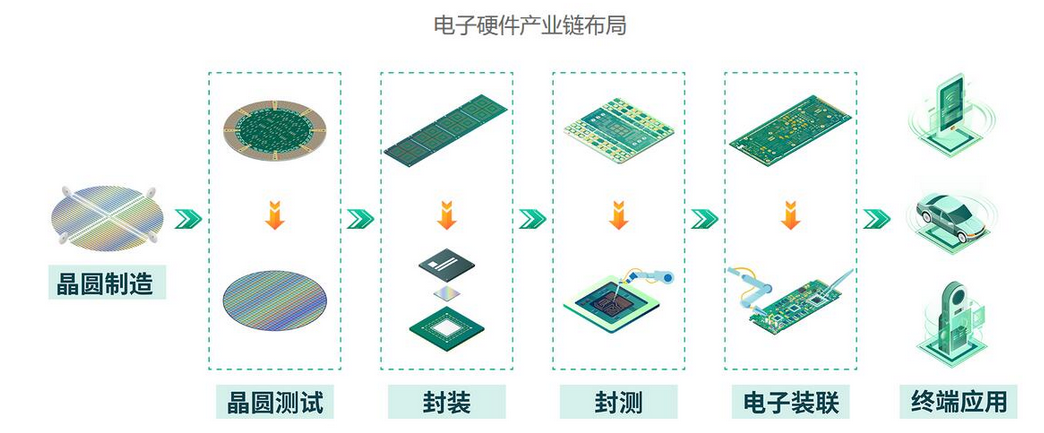

Electronics Industry Chain

High-frequency microwave board production should pay attention to the issue of

1.Disposal of engineering materials: When disposing of the customer's files for CAM, we must grasp the internal meaning of two aspects, one is to treat seriously and understand thoroughly the manufacturing precision requirements of the conveyor line; the other is to make the appropriate process reimbursement in accordance with the precision requirements and the integration of the factory's experience in the production process.

2.Under the material: general printed circuit board under the material are used shears or semi-automatic openers, but for microwave media materials can not be discussed together, according to the special nature of the different media, and select different under the material method, mostly milling,cutting as the main, so as not to affect the smoothness of the material as well as the quality of the board surface.

3.Drilling: For different media materials, not only the parameters of drilling are different, but also the top angle of the drill, the length of the edge, the helix angle and so on have their own special requirements, for aluminum-based, copper-based microwave media materials, the form of drilling processing is also different, in order to prevent the emergence of burrs.

4.Conductor hole grounding:under ordinary circumstances, the conductor hole is considered appropriate to use chemical copper sinking method of grounding, chemical copper sinking generally use chemical method or plasma method of disposal, from the safety point of view, we think it is appropriate to use the plasma method, the effect is wonderful; and aluminum-based microwave media materials, if the general chemical copper sinking, there is a great degree of difficulty, the general proposal is considered appropriate to use metal conductive material drilling hole grounding, to prevent burrs. For aluminum-based microwave medium materials, it is quite difficult to use general chemical copper sinking, so it is generally recommended to use metal conductive materials to fill holes for grounding, but the resistance of holes is generally less than 20m?

5.Graphic transfer:this process is to protect the graphic precision of a critical process.In the selection of photoresist,wet film,dry film and other gelatin,must satisfy the requirements of graphic precision; at the same time photolithography or exposure machine light source must also meet the needs of the process.

6.Rot carving:this process should strictly control the rot carving process parameters,such as: the content of the components of the rot carving solution,the temperature of the rot carving solution,rot carving speed. Guarantee that the wire edges are clear, no burrs,notches,wire precision within the tolerance requirements.To be practical and realistic to do a good job of this point, the need for fine work,is very indispensable.

7.Coating: high-frequency microwave board lead wire on the final coating of tin-lead alloy,tin strontium alloy,strontium alloy, silver, gold and so on. However, red gold plating is more widely available.

8.Molding: high-frequency microwave board molding and printed circuit boards, digital control milling is the main.But the milling method for different materials, there is a very big difference. The milling of metal-based microwave boards requires the use of neutral cooling liquid for cooling, and the parameters of milling are also quite different.

In the production of high-frequency microwave boards, in addition to paying attention to the above issues, we must also be careful about the hot air whole daily tin cylinder temperature, air pressure volume and rotation, indentation and scratches in the clamping process. Only serious attention to each link carefully, the ability to really make products that meet the standards.