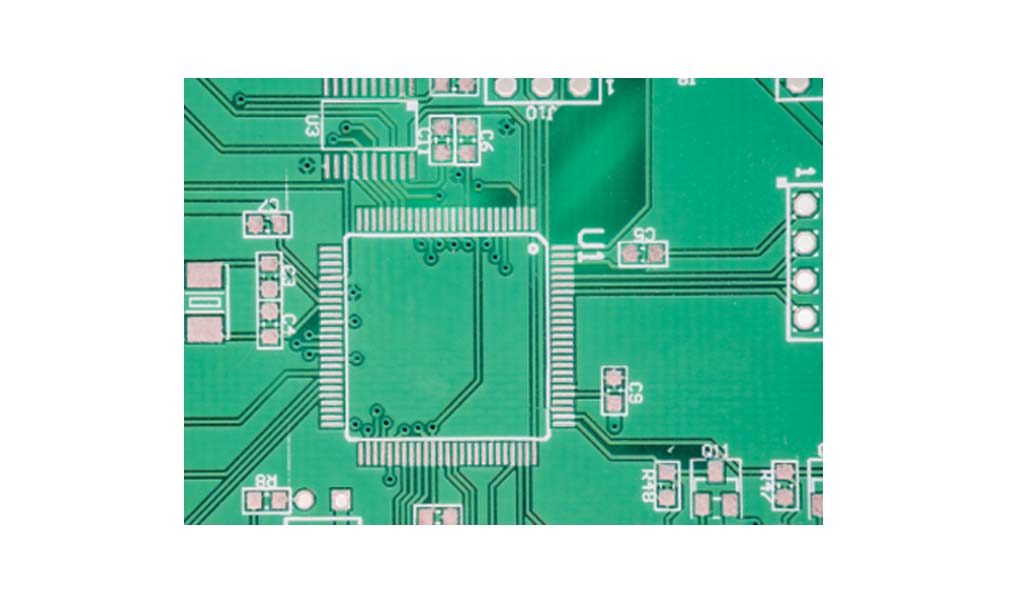

An empty PCB board is a PCB substrate that has not yet been installed with any electronic components. It is usually composed of one or more layers of thin sheet materials (such as fiberglass and resin) coated with conductive copper foil.

The manufacturing process of an empty PCB board usually includes the following steps:

1. Material selection: Select the substrate material suitable for the specific application, such as FR-4 fiberglass plastic, metal substrate, etc.

2. Printing: Print the designed circuit pattern on the surface of the substrate, and use chemical methods to remove the unnecessary copper foil, leaving the required wiring pattern.

3. Acid etching: The unprotected copper foil is removed through the acid etching process to form the conductor and pad.

4. Processing: The PCB is processed by drilling, cutting, etc. to meet the design requirements.

5. Surface treatment: If necessary, a metal protective surface is plated on the pad to reduce oxidation and improve solderability.

The following are the main classifications of empty PCB boards and their usage scenarios:

1. Classification by number of layers

Single-layer PCB board

Features: There is only one layer of copper foil, and all electrical connections are completed on the same layer, which is low in cost.

Application scenarios: Mainly used for simple electronic devices such as remote controls, low-power devices, calculators, etc.

Double-layer PCB board

Features: There are two layers of copper foil, and the upper and lower layers are electrically connected through vias.

Application scenarios: Suitable for slightly complex circuit designs, such as power adapters, audio equipment, and home electronics.

Multi-layer PCB board

Features: Contains three or more layers of copper foil, and the layers are connected through vias. Usually the number of layers of a multi-layer PCB board can range from 4 to dozens of layers.

Application scenarios: Used for complex electronic devices such as computer motherboards, servers, mobile phones, industrial equipment, avionics equipment, etc.

2. Classification by flexibility

Rigid PCB board

Features: Rigid PCB boards are made of rigid materials, such as FR4 materials. They cannot bend, have a stable structure, and are suitable for fixed installation.

Application scenarios: Widely used in almost all types of electronic devices, especially electronic components that need to be fixed and immobile, such as desktop computers, televisions, automotive electronics, etc.

Flexible PCB board

Features: Flexible PCB boards are made of flexible materials, such as polyimide (PI). They can be bent and folded, suitable for applications that require flexible connections.

Application scenarios: Mainly used in devices that require flexibility, such as cameras, wearable devices (smart watches), displays, medical devices, and some connection modules in mobile phones.

Rigid-flexible PCB board

Features: Combines rigid and flexible parts, and is usually used for complex circuit designs that require both rigidity and flexibility.

Application scenarios: Used in devices with limited space and requiring complex three-dimensional layouts, such as digital cameras, modules in consumer electronics, aviation and military equipment, etc.

3. Classification by special use

High-frequency PCB board

Features: Designed for high-frequency signal transmission, using specific materials (such as PTFE) to reduce signal attenuation and interference.

Application scenarios: Mainly used in radio frequency (RF) communication equipment, satellite communications, microwave transmission equipment, etc.

Metal-based PCB board

Features: Metal (such as aluminum, copper) is used as the substrate material, which has excellent thermal conductivity and mechanical strength.

Application scenarios: Used for high-power LED lighting, automotive lights, industrial power supply equipment, etc., especially suitable for applications with high heat dissipation requirements.

High-density interconnect PCB (HDI PCB)

Features: It has a higher wiring density, usually using blind and buried via technology, which can reduce the size of the board and improve signal speed and reliability.

Application scenarios: Widely used in devices with high volume and performance requirements such as smartphones, tablets, wearable devices, etc.

Empty PCB boards have been widely used in various fields according to their types and structures. From simple consumer electronics to complex aerospace equipment, different types of PCB boards provide basic electrical connections and structural support for various devices. When choosing a PCB board, it is necessary to select the appropriate board and design scheme according to specific application requirements, such as electrical performance, mechanical strength, temperature requirements, etc.