The rapid development of modern communication industry has ushered in an unprecedented large market for the manufacturing of high-frequency copper-clad laminates. As one of the fundamental data for the manufacturing of high-frequency copper-clad laminates, the data composition and related performance indicators of the adhesive sheet determine the achievement and processability of the final product performance indicators in its design.

Given the increasing use of high-frequency PTFE dielectric copper-clad laminates in design, especially the growing demand for PTFE dielectric high-frequency multilayer board design in recent years, it has brought unprecedented opportunities and challenges to the vast number of printed board manufacturing enterprises. At the same time, higher performance indicators are required for the manufacturing of high-frequency copper-clad laminates using basic raw materials.

As is well known, for the high-frequency substrate data of polytetrafluoroethylene, the performance indicators and processability of the adhesive sheet data determine the application field of high-frequency copper-clad laminates. In addition, the multi-layer manufacturing technology of high-frequency printed circuit boards, after focusing on solving the characteristic impedance control technology in the manufacturing technology of high-frequency multi-layer printed circuit boards, has become a thorny problem that every designer and process personnel must face in selecting the appropriate bonding sheet data system to achieve multi-layer manufacturing of high-frequency PCB boards.

The current situation of adhesive sheet data

Throughout the development history of the high-frequency copper-clad laminate industry, the innovation of adhesive sheet data is aimed at meeting the performance requirements of copper-clad laminates

Under the requirement of quotas, we are gradually entering a new era.

There are two types of adhesive film modes based on the resin system selected from the adhesive film data. One is the data of thermoplastic resin system adhesive sheets; Secondly, it is the data of thermosetting resin adhesive sheets.

Thermoplastic film bonding data

For the market demand of high-frequency copper-clad laminates, twenty years ago, it was in the manufacturing stage of single and double-sided high-frequency boards. With the rapid development of modern communication technology, there is an increasing amount of high-frequency copper-clad laminate data. Faced with the trend of multi-layer technology development in design and processing, the importance of adhesive sheet data is highlighted.

Looking back at the entire process of the emergence and development of high-frequency multilayer boards, thermoplastic film bonding data is a good choice for both design selection and RF multilayer board processing.

Usually, in the layout process, thin films are placed cross over to achieve multi-layer assembly. Among them, what is often not recognized by people but needs attention is that for the selected thermoplastic film bonding data, it must meet the heating process in the lamination process. In other words, the melting point of the bonding data of this thermoplastic film needs to be lower than the melting point of the high-frequency copper-clad laminate dielectric board - polytetrafluoroethylene resin at 327 ℃ (6200F).

As the laminating temperature increases and exceeds the melting point of the thermoplastic film, the adhesive film begins to flow. With the help of uniform pressure applied by the laminating equipment to the mounting plate, it is filled between the copper layer lines on the surface of the layer to be bonded.

Usually, the bonding data of thermoplastic films can be roughly divided into two types according to the laminating temperature.

1. Temperature control for lamination at 220 ℃

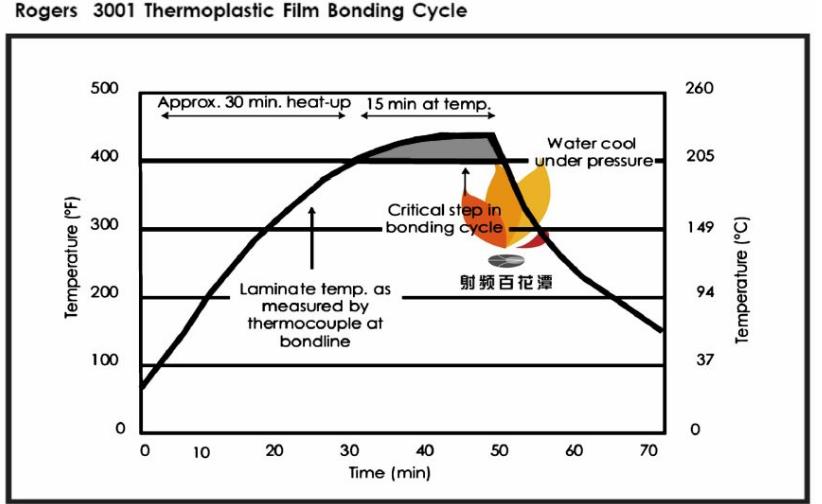

The first application of bonding data for such low-temperature thermoplastic films is Rogers 3001.

Rogers 3001 film lamination parameter control

In the rolling river of time, similar thermoplastic film bonding data are also available for the FV6700 film (laminated temperature control schematic, see Figure 2) and Cuclad 6700 film (laminated temperature control schematic, see Figure 3), the honored products of Nelco and Arlon, which provide multi-layer bonding for their respective customers in the market.

2. 290 ℃ laminating temperature control

Different from the lower temperature bonding data mentioned above, there is another widely used thermoplastic film bonding data with higher lamination temperature, which is DuPont's honor product - Cuclad 6700.

How to choose FEP bonding data often depends on the subsequent process route of multilayer RF circuit board processing, including the thermal process experienced, the melting point of the bonding film used, reliability requirements, etc. Of course, the process capability of multilayer printed boards is also an aspect that needs to be examined.