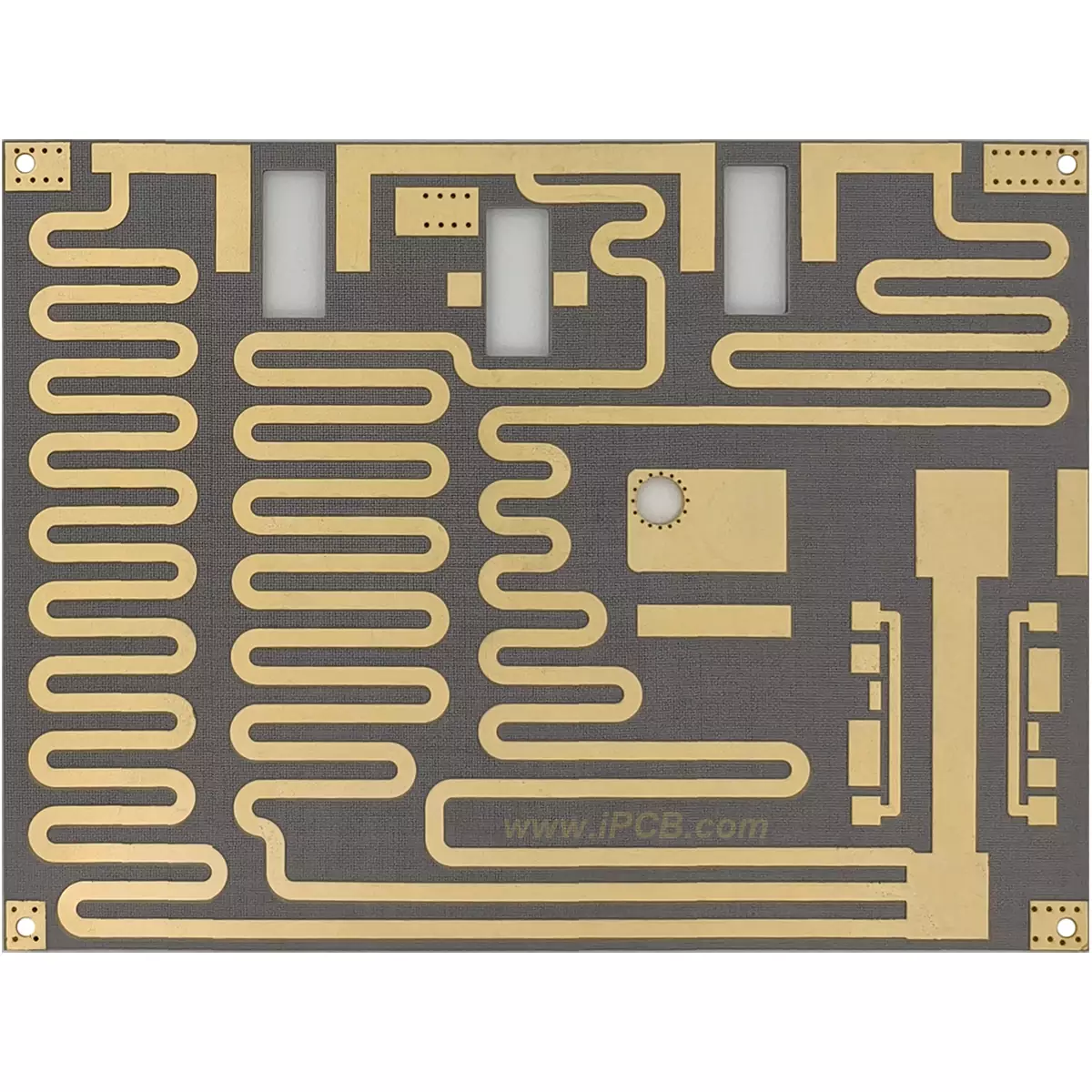

Product: F4BM PCB

Material: PTFE F4BM

Layer: 1-2L

F4BM dielectric constant: 2.2-3.5

F4BM medium thickness: customizable

F4BM base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 0.2-12mm

Solder mask colors: green, red, blue

Surface treatment: Immersion gold

Application: antennas, satellite, communication

F4BM is made by scientifically formulating and rigorously pressing glass cloth, semi cured sheet, and PTFE (polytetrafluoroethylene) resin. Its electrical performance has been improved compared to the F4B series, mainly due to a wider range of dielectric constants, lower dielectric loss tangent, increased resistance, and more stable performance.

F4BM Datasheet

Dielectric constant (DK): 2.2-3.5

Loss factor (DF): 0.0010-0.0018

Thickness (customizable): 0.127 ± 0.01mm, 0.254 ± 0.02mm, 0.508 ± 0.04mm, 0.762 ± 0.05mm, 1.016 ± 0.05mm, 1.524 ± 0.06mm, 2.0 ± 0.08mm, 3.0 ± 0.09mm, 0.1 ± 0.01mm, 0.2 ± 0.02mm, 0.8 ± 0.05mm, 1.575 ± 0.06mm, 2.5 ± 0.08mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm

Sizes (customizable): 460 * 610mm, 500 * 600mm, 850 * 1200mm, 914 * 1220mm, 1000 * 1200mm, 250 * 300mm, 350 * 380mm, 500 * 500mm, 840 * 840mm, 1000 * 1500mm

Advantages of F4BM: low loss, diversified size, cost savings, radiation resistance, low exhaust, large quantity, high cost-effectiveness

Application areas: phase shifters, passive components, power dividers, couplers, combiners, feed networks, phased array antennas, satellite communications, base station antennas

F4BM model

PTFE fiberglass cloth coated copper foil board F4B: F4B255, F4B265

PTFE fiberglass cloth coated copper foil board F4BM: F4BM217 F4BM220、F4BM233、F4BM245、F4BM255、F4BM265、F4BM275、F4BM294、F4BM300

PTFE fiberglass cloth coated copper foil board F4BME: F4BME217 F4BME220、F4BME233、F4BME245、F4BME255、F4BME265、F4BME275、F4BME294、F4BME300

PTFE fiberglass cloth ceramic filled substrate series F4BTM: F4BTM298 F4BTM300、F4BTM320、F4BTM350

PTFE fiberglass cloth ceramic filled substrate series F4BTME: F4BTME298 F4BTME300、F4BTME320、F4BTME350

Polytetrafluoroethylene fiberglass cloth ceramic film substrate series F4BM-2-A: F4BM-2-A255 F4BM-2-A265、F4BM-2-A294、F4BM-2-A300

Polytetrafluoroethylene fiberglass cloth ceramic film substrate series F4BME-2-A: F4BME-2-A255 F4BME-2-A265、F4BME-2-A294、F4BME-2-A300

PTFE ultra-thin and ultrafine fiberglass cloth ceramic filled substrate F4BTMS series: F4BTMS220 F4BTMS233、F4BTMS255、F4BTMS265、F4BTMS294、F4BTMS300、F4BTMS350、F4BTMS430、F4BTMS450、F4BTMS615、F4BTMS1000

| Product iPCB.com | Dk (εr) @10G | Df (tgδ)@10G | TcDk ppm/ºC | Density (g/cm3) | Peel strength (1OZ)N/mm | Thermal expansion coefficient ppm/ºC | ||||

| X | Y | Z | ||||||||

| F4BM217 | 2.17±0.04 | 0.0010 | -150 | 2.17 | >1.8 | 25 | 34 | 240 | ||

| F4BM220 | 2.20±0.04 | 0.0010 | -142 | 2.18 | >1.8 | 25 | 34 | 240 | ||

| F4BM233 | 2.33±0.04 | 0.0011 | -130 | 2.20 | >1.8 | 22 | 30 | 205 | ||

| F4BM245 | 2.45±0.05 | 0.0012 | -120 | 2.22 | >1.8 | 20 | 25 | 187 | ||

| F4BM255 | 2.55±0.05 | 0.0013 | -110 | 2.25 | >1.8 | 16 | 21 | 173 | ||

| F4BM265 | 2.65±0.05 | 0.0014 | -100 | 2.25 | >1.8 | 14 | 17 | 142 | ||

| F4BM275 | 2.75±0.05 | 0.0015 | -92 | 2.28 | >1.8 | 14 | 16 | 112 | ||

| F4BM294 | 2.94±0.06 | 0.0017 | -85 | 2.29 | >1.8 | 12 | 15 | 98 | ||

| F4BM300 | 3.00±0.06 | 0.0018 | -80 | 2.29 | >1.8 | 12 | 15 | 95 | ||

| F4BME217 | 2.17±0.04 | 0.0010 | -150 | 2.17 | >1.6 | 25 | 34 | 240 | ||

| F4BME220 | 2.20±0.04 | 0.0010 | -142 | 2.18 | >1.6 | 25 | 34 | 240 | ||

| F4BME233 | 2.33±0.04 | 0.0011 | -130 | 2.20 | >1.6 | 22 | 30 | 205 | ||

| F4BME245 | 2.45±0.05 | 0.0012 | -120 | 2.22 | >1.6 | 20 | 25 | 187 | ||

| F4BME255 | 2.55±0.05 | 0.0013 | -110 | 2.25 | >1.6 | 16 | 21 | 173 | ||

| F4BME265 | 2.65±0.05 | 0.0014 | -100 | 2.25 | >1.6 | 14 | 17 | 142 | ||

| F4BME275 | 2.75±0.05 | 0.0015 | -92 | 2.28 | >1.6 | 14 | 16 | 112 | ||

| F4BME294 | 2.94±0.06 | 0.0017 | -85 | 2.29 | >1.6 | 12 | 15 | 98 | ||

| F4BME300 | 3.00±0.06 | 0.0018 | -80 | 2.29 | >1.6 | 12 | 15 | 95 | ||

| F4BTM298 | 2.98±0.06 | 0.0018 | -78 | 2.25 | >1.6 | 15 | 16 | 78 | ||

| F4BTM300 | 3.00±0.06 | 0.0018 | -75 | 2.25 | >1.6 | 15 | 16 | 72 | ||

| F4BTM320 | 3.20±0.06 | 0.0020 | -75 | 2.20 | >1.6 | 13 | 15 | 58 | ||

| F4BTM350 | 3.50±0.07 | 0.0025 | -60 | 2.20 | >1.6 | 10 | 12 | 51 | ||

| F4BTME298 | 2.98±0.06 | 0.0018 | -78 | 2.25 | >1.4 | 15 | 16 | 78 | ||

| F4BTME300 | 3.00±0.06 | 0.0018 | -75 | 2.25 | >1.4 | 15 | 16 | 72 | ||

| F4BTME320 | 3.20±0.06 | 0.0020 | -75 | 2.20 | >1.4 | 13 | 15 | 58 | ||

| F4BTME350 | 3.50±0.07 | 0.0025 | -60 | 2.20 | >1.4 | 10 | 12 | 51 | ||

Product: F4BM PCB

Material: PTFE F4BM

Layer: 1-2L

F4BM dielectric constant: 2.2-3.5

F4BM medium thickness: customizable

F4BM base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 0.2-12mm

Solder mask colors: green, red, blue

Surface treatment: Immersion gold

Application: antennas, satellite, communication

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.