PTFE and Teflon refer to Polytetrafluoroethylene, which is welcomed by many product manufacturers due to its excellent usage characteristics (high-temperature resistance, low-temperature resistance, corrosion resistance, etc.).

(1) High-temperature resistance - Used at operating temperatures of up to 250℃. PTFE Teflon PCB

(2) Low-temperature resistance - 5% elongation at -196℃.

(3) Weather resistance - best anti-aging effect.

(4) Corrosion resistance - resistant to strong acids and alkalis.

Millimeter wave technology is the core of 5G mobile communication technology, which can significantly increase channel capacity and data transmission rate, thanks to its very wide absolute bandwidth. This characteristic makes millimeter waves in the application of high-frequency copper-clad laminates has been greatly emphasized. Among them, polytetrafluoroethylene (PTFE) sheet occupies an important position in applying high-frequency copper-clad laminates due to its excellent microwave performance. In the past, most imported PTFE sheets were used in the market, but with the development of domestic technology, they have begun to be localized and can replace imported products. There are many domestic plate manufacturers of PTFE materials that can meet the high production needs of customers, in terms of price is also more cost-effective than foreign substrates, this article will not be introduced to the domestic plate manufacturers, if there is a need to consult iPCB further.

The high-frequency characteristics of the 5G base station make its operating frequency much higher than 4G, which requires the use of materials that can support higher frequencies, such as high-frequency copper-clad laminates. One of the key materials for high-frequency copper-clad laminates is PTFE, which is ideal for high-frequency signal transmission because of its excellent dielectric properties and heat resistance. As the 56-frequency spectrum expands to higher frequency bands, the demand for high-frequency PCBs is also growing, directly driving the demand for PTFE material usage.

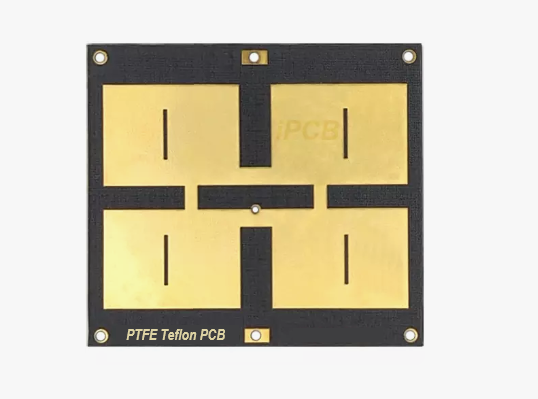

PTFE Teflon PCB has outstandingly good overall performance, high-temperature resistance, corrosion resistance, non-stick, self-lubricating, excellent dielectric properties, and a very low coefficient of friction. Application areas are:

(1) Microwave, radio frequency, radar

(2) Phase shifters, passive components

(3) Power divider, coupler, combiner

(4) Feeder networks, phased array antennas

(5) Satellite communications, base station antennas

High-frequency boards on the copper foil surface roughness requirements are quite strict and do not allow drilling surface burrs, phi, and other issues. At the same time, because the PTFE resin is soft, when drilling the plate deformation will cause the glass cloth cutting and pulling force to be too large causing the plate to lose white. Therefore, when drilling holes, thick aluminum sheets and high-density pads are used to prevent problems such as burrs, sharp edges, and whitening. The following are the drilling process issues that require special attention during the production of PTFE Teflon PCB:

(1) Hole wall roughness ≤ 40um;

(2) No burrs in the hole, no hole phi;

(3) Hole white zone from the edge of the hole ≤ 2.0mm;

(4) No deformation of the hole, normal hole type;

(5) After plating the hole wall without plating the tumor or plating the tumor does not affect the performance of the printed board.