What are the advantages of PCB high-frequency board?

There is a very popular type of PCB circuit board, which is PCB high-frequency board. PCB high-frequency board has always been favored by the market since its invention, and since the emergence of induction heating technology, it has been at the forefront. Its extremely high frequency is active in promoting high-speed information processing systems in the communication industry and network technology fields, and it also meets the requirements of many high-precision parameter instruments with its own advantages. So what are the advantages that make this PCB high-frequency board stand so strong and popular?

1. PCB high-frequency board has high efficiency

Generally speaking, the consumption of PCB high-frequency board is due to their low dielectric constant, so the consumption is naturally smaller than other circuit boards. Under such excellent innate conditions, induction heating technology at the forefront of technological development can also meet the demand for target heating, thereby making the efficiency of high-frequency circuit boards very high. Of course, while pursuing efficiency, we cannot abandon environmental protection.

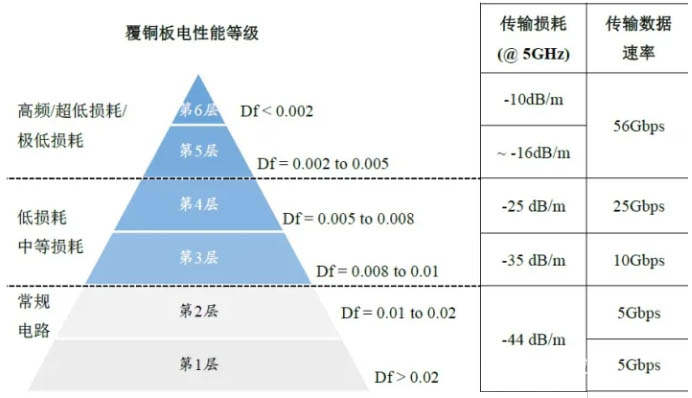

DF of PCB high-frequency board materials

2. PCB high-frequency board has fast speed

As is well known, the transmission rate is directly proportional to the dielectric constant. In electrical principles, the transmission rate is inversely proportional to the square root of the dielectric constant, meaning that the larger the dielectric constant, the slower the transmission rate; The smaller the dielectric constant, the faster the transmission rate. This is also one of the reasons why PCB high-frequency boards are loved by everyone. It uses special materials that can ensure the characteristic of low dielectric constant, while also ensuring the transmission rate and making the operation of the circuit board relatively stable.

3. PCB high-frequency board has high adjustability

PCB high-frequency boards widely used in various industries for precision metal material heating treatment requirements can not only achieve heating of parts at different depths in their processes, but also focus on heating local characteristics. Whether it is surface or deep level, concentrated or dispersed heating pipes, they can be easily completed.

4. PCB high-frequency board has strong tolerance

The environment affects the composition of the medium, so PCB high-frequency boards still have requirements for the environment, especially in the south where humid weather is more common. PCB high-frequency boards can adapt well to such environments, and high-frequency circuit boards made of materials with extremely low water absorption can challenge such environments. At the same time, it is best to make PCB circuit boards resistant to chemical corrosion, so that they can withstand moisture and high temperatures in humid environments, and have great peel strength.

How to choose the material for PCB high-frequency board?

1. Manufacturability

For example, the effectiveness of multiple pressing, temperature efficiency, CAF/heat resistance, mechanical toughness (good reliability), and fire rating.

2. Various performance indicators that match the product (such as power, performance stability, etc.)

Low loss, stable Dk/Df parameters, low dispersion, small coefficient of variation with frequency and environment, small material thickness and adhesive content tolerance (good impedance control) are all factors considered; If the wiring is long, low roughness copper foil should also be considered. Another point is that the design of high-speed circuits requires simulation in the early stages, and the simulation results are the reference standards for the design.

3. Timely availability of materials

Many PCB high-frequency board procurement cycles are very long, even 2-3 months, and it is necessary to communicate with PCB high-frequency board manufacturers in advance to prepare materials as early as possible.

4. PCB high-frequency board cost factor cost

Check the price sensitivity of the product, whether it is a consumer product or an application in the fields of communication, medical, industrial, or military.

5. Applicability of laws and regulations, etc

To integrate with environmental regulations of different countries and meet requirements such as RoHS and halogen-free.

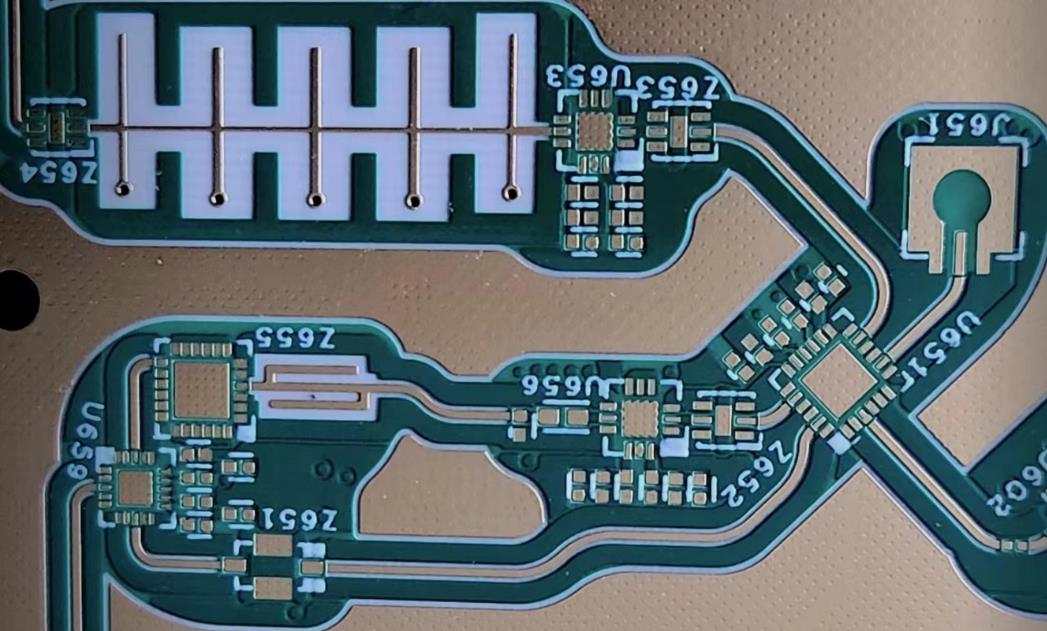

PCB high-frequency board

6. The operating speed of high-speed digital circuits is also a major factor to consider when selecting high-frequency PCB boards.

The higher the speed of the circuit, the smaller the Df value of the selected PCB should be. Circuit boards with medium to low loss will be suitable for 10Gb/s digital circuits. Boards with lower losses are suitable for 25Gb/s digital circuits; The ultra-low loss board will adapt to faster high-speed digital circuits, with speeds of 50Gb/s or higher.

From the perspective of PCB high-frequency board material Df

Circuit boards with Df ranging from 0.01 to 0.005 are suitable for digital circuits with an upper limit of 10Gb/s.

Df ranges from 0.005 to 0.003, and circuit boards are suitable for digital circuits with an upper limit of 25Gb/s.

Circuit boards with Df not exceeding 0.0015 are suitable for 50Gb/S or even higher speed digital circuits.

The above are the main factors to consider when choosing suitable high-frequency boards, and practical applications still need to be analyzed based on specific cases.

PCB design needs to consider all temperature changes to avoid quality loss and decay over time. Most PCB high-frequency boards require a temperature range of no more than 350 degrees Celsius for application. Considering that some PCB high-frequency board materials have higher decay temperatures, it becomes crucial to consider them during the PCB high-frequency board design phase.

Design requirements for drive circuit. The design of any specific driving circuit requires a stable impedance. However, considering that the dielectric constant (Dk) range of PCB high-frequency board materials is wider than that of FR-4 materials, impedance stability can be maintained. In addition, the efficiency of these types of PCB high-frequency board designs has also been improved. In most cases, the operation of most circuits operates at an impedance value of 50 Ω. It is also necessary to match this value with other circuit components to ensure maximum power transfer between the output and input. In addition, the circuit needs to avoid generating a large number of standing waves to eliminate any load reflections.

However, the good news is that there are many software tools on the market, such as computer-aided engineering, that allow for diverse and critical material selection for PCB high-frequency board design. Therefore, the deployment of such tools makes it possible to select PCB high-frequency boards with preferred dielectric constants to ensure impedance matching and stability.

When selecting PCB high-frequency board materials, other key factors such as dissipation factor prove to be crucial. PCB high-frequency board design engineers should consider important material characteristics, such as power loss, which increases with the increase of operating frequency. Another important characteristic is thermal conductivity, which determines the conduction content of the material's head. For example, the amplifier of a missile guidance system can cause electrical and mechanical changes in the material properties of the PCB high-frequency board, as long as the heat cannot be properly managed. Therefore, it may cause malfunctions and serious problems.