PCB deformation board warpage refers to the PCB board in the processing, the use of the process of shape changes, mainly including bending, warping, twisting and so on. PCB deformation warpage will affect the normal use of PCB circuit boards, and even lead to PCB circuit board damage, so it is necessary to carry out in-depth analysis and research on the causes of its production.

In PCB milling, how to reduce or eliminate the deformation caused by different data characteristics or processing warpage has become one of the problems faced by PCB manufacturers.

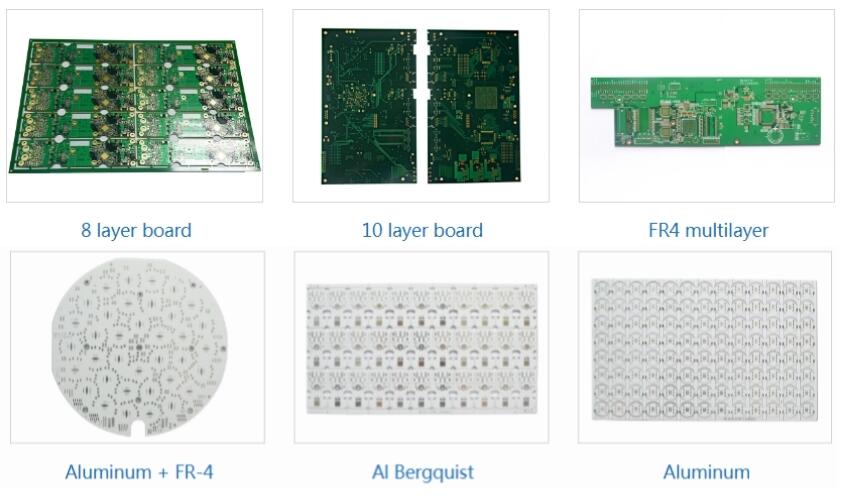

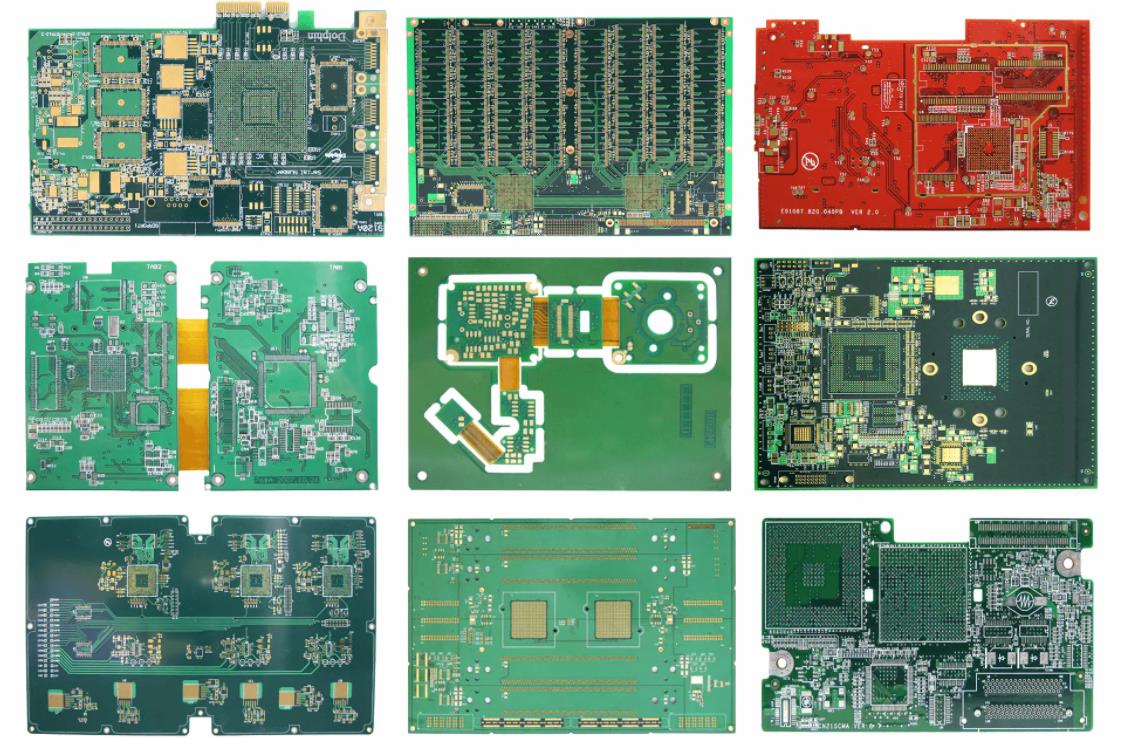

PCB circuit board

The following are some of the PCB board deformation board warpage reasons:

1.Unreasonable PCB design

PCB board design is an important factor affecting its deformation board warpage.If the design is not reasonable, it will lead to deformation of the PCB board in the processing and use of the process of warpage.For example, if the length and width of the board is not reasonable, or the layout of the components on the board is not reasonable, will lead to deformation of the PCB board warpage.

2.Improper selection of data

The selection of PCB data is also an important factor that affects the deformation of the board.Different data have different characteristics, such as coefficient of thermal expansion.Density, etc.If the choice of data and PCB application environment does not match, it will lead to PCB deformation board warpage.

3.PCB processing technology is not appropriate

PCB processing technology is also an important factor affecting the deformation of the board warpage.If the processing technology is not appropriate, it will lead to PCB deformation board warpage.For example, if the welding temperature is too high or too long, it will lead to PCB deformation board warpage, if the drilling depth is too large or hole diameter is too small, it will lead to PCB deformation board warpage.

4.Improper use of the environment

The use of the PCB board environment is also an important factor affecting the deformation of the board warpage.If the use of the environment is not appropriate, it will lead to PCB deformation board warpage.For example, if the ambient temperature is too high or humidity is too high, it will lead to PCB warpage.If used in a high-frequency electromagnetic field environment, it will lead to PCB deformation and warpage.

5.The weight of the PCB board itself will cause the board to be depressed and deformed.

General soldering furnace will use the chain to drive the PCB board in the soldering furnace forward, if the board has too heavy parts, or the board size is too large, because of its own weight and the middle of the concave phenomenon, resulting in board bending.

6.The depth of V-Cut and connecting strips will affect the amount of warpage of deformed boards.

V-Cut is to cut grooves in the original sheet, so the place where the V-Cut occurs will be prone to deformation and board warpage.

7.Deformation caused by the PCB processing process

The cause of deformation board warpage during PCB processing is very complex,which can be divided into two kinds of stresses:thermal stress and mechanical stress.Thermal stress is mainly generated in the lamination process, mechanical stress is mainly generated by the board stacking.Transportation.Baking process.

Below is a brief discussion of the process sequence.

Laminates from the material:laminates press size,hot plate temperature difference between different areas,will lead to different areas in the process of lamination resin curing speed and degree of subtle differences, but also produce local stress, in the future processing of the gradual release of deformation of the board warpage.

Pressing:PCB pressing process is the main process of generating heat stress, which is released in the subsequent drilling, shaping or baking processes, resulting in board deformation and board warpage.

Soldermask, characters and other baking processes: Since soldermask ink can not be stacked on top of each other during curing,PCB boards are placed vertically in the racks for baking and curing,and the boards are easily deformed and warped under the effect of self-weight or strong winds from the baking oven.

Hot air solder levelling:the entire hot air solder levelling process for the sudden heat and cold process, there will inevitably be thermal stress, resulting in micro-strain and overall deformation of the board warpage area.

Storage:PCB boards in the semi-finished stage of storage are generally inserted in the shelf, the shelf is not suitable for adjusting the tension, or storage process, such as stacking boards will make the boards produce mechanical deformation board warpage.

In addition to the above factors,there are many other factors that affect the deformation of the PCB board warpage, once you find the PCB board deformation board warpage, you need to immediately check the reasons for the occurrence of, and make improvements.

PCB circuit board

PCB deformation board warpage preventive measures

1.Reasonable design PCB

When choosing the board,you need to choose the right board according to the application environment.For example, if the application environment has a higher temperature, you need to choose a board with a smaller coefficient of thermal expansion.If the application environment is more humid, you need to choose a better moisture-proof performance of the board.

2.Reasonable layout of components

In order to avoid signal interference between components, the distance between components should be reasonable.If the distance between components is too small, it will cause signal interference.If the distance between components is too large, it will lead to a reduction in the space utilisation of the board.The height of the components should also be reasonable.If the height of the components is too small, it will cause signal interference.If the height of the components is too large, it will lead to a reduction in the space utilisation of the board.

3.Selection of suitable processing technology

3.1.Select the appropriate soldering temperature and time

During the soldering process, it is necessary to select the appropriate soldering temperature and time.If the soldering temperature is too high or too long, it will lead to PCB board deformation board warpage.If the soldering temperature is too low or the time is too short, it will lead to weak soldering.

3.2.Select the appropriate drilling depth and hole diameter

In the drilling process, you need to choose the appropriate drilling depth and hole diameter.If the drilling depth is too large or the hole diameter is too small, it will lead to PCB deformation and board warpage.

In addition to the above factors, the causes of PCB warpage and preventive measures for PCB warpage.There are many other factors affecting PCB warpage, once you find the PCB warpage, you need to immediately check the causes and make improvements.