In the process of PCBA,reflow soldering is a very important process, the role of reflow soldering is to use solder paste to solder the PCB board and components together. Reflow soldering has an internal heating circuit, the air or nitrogen heated to a high enough temperature after blowing to the PCB board has been affixed to the components,so that the components on both sides of the solder melted and bonded to the motherboard.The advantage of this process is that the temperature is easy to control, the soldering process can also avoid oxidation, manufacturing costs are also easier to control.

Reflow soldering has the advantages of fast, convenient, can simultaneously weld multiple pieces of soldering,the time is greatly reduced, can reduce the cost of installation and production; after welding the connection performance is better,the joints are solid,with higher reliability, strength and high quality,reflow soldering operation requirements are not high,applicable to any size of the soldered parts, can be used in a variety of ways to operate; it can be automated, and does not take up space,can be better suited to the automation of small products.It can be operated automatically and does not take up much space,so it can be better applied to the automatic assembly of small products,which can greatly reduce the labour cost during installation.

The principle of reflow soldering is very simple, it is the circuit board soldering parts in advance to apply the appropriate amount of solder,and then paste the surface assembly components,and then use the external heat source to make the solder flow again to the welding of a welding process, reflow soldering heating process can be divided into preheating, heat preservation,soldering and cooling of four temperature zones.

Reflow soldering is mainly two ways to achieve:

1.Along the direction of travel of the transmission system, so that the circuit board through the furnace in order of the four temperature zones.

2.The circuit board is parked in a fixed position, under the action of the control system,in accordance with the four temperature regions of the gradient law regulation,control of temperature change.

We can understand the internal structure of the reflow soldering machine to better grasp the principle of reflow soldering.

reflow soldering

Reflow soldering machine structure composition:

Reflow soldering machine is mainly composed of four parts: transmission system, control system, heating system and cooling system. Due to the heating of different pipelines, the internal composition of the structure will be different, the following we will heat the reflow soldering machine as an example:

1.Transmission system: transmission system mainly mesh belt and chain type two types,which can be placed arbitrarily mesh belt transmission of printed boards, suitable for single-panel soldering, which overcomes the heat of the printed board may cause the defects of the depression, but the dual-panel soldering and wiring equipment has limitations in the use of transmission; chain transmission is the PCB is placed in the stainless steel chain lengthening pins on the transmission of the width of the chain is adjustable to adapt to different printed board widths.The width of the chain can be adjusted to adapt to the requirements of different board width, but for wide or ultra-thin boards may cause depression after heating.

2.Control system: the control system is the hub of the reflow soldering machine, its operating pipeline,flexibility and the functions it has a direct impact on the use of equipment,advanced reflow soldering equipment has all adopted a computer or PLC control pipeline,the use of computers rich in hardware and software resources to greatly enrich and improve the function of the reflow soldering equipment,and effectively ensure that the quality of production and management improvement.

3.Heating system: the heating system of each temperature zone are used in a forced independent loop, independent control up and down the heating pipe, so that the furnace chamber temperature is accurate,uniform and large heat capacity,which the temperature controller through the PID control to maintain the temperature at the set value,the temperature sensor using thermocouples to measure the temperature of the gas stream.

4.Cooling system:cooling system mainly heat exchanger cooling and fan cooling two kinds,PCB board after reflow soldering, must be immediately cooled, in order to get a good welding effect.In the cooling system due to the flux is easy to condense,must be regularly checked and cleaned flux flux screening programme on the flux,otherwise the decline in the efficiency of the heat cycle will reduce the efficiency of the cooling system,so that the cooling deterioration, resulting in a decline in the quality of the product soldering.

In order to improve the quality of soldering,we all need to test the reflow oven temperature.The four temperature zones of the reflow soldering equipment (warming zone,preheating constant temperature zone,reflow soldering zone, cooling zone) have different temperature zones with special functions.

Then the reflow soldering temperature test contains that several aspects?

1.Reflow soldering furnace temperature test

In accordance with the furnace temperature tester operating specifications and operating procedures for the requirements of the temperature sensor welded to the PCB board corresponding test points

In accordance with the furnace temperature tester operating specifications and operating procedures of the requirements of the furnace temperature tester and the PCB board placed on the track of the welding equipment

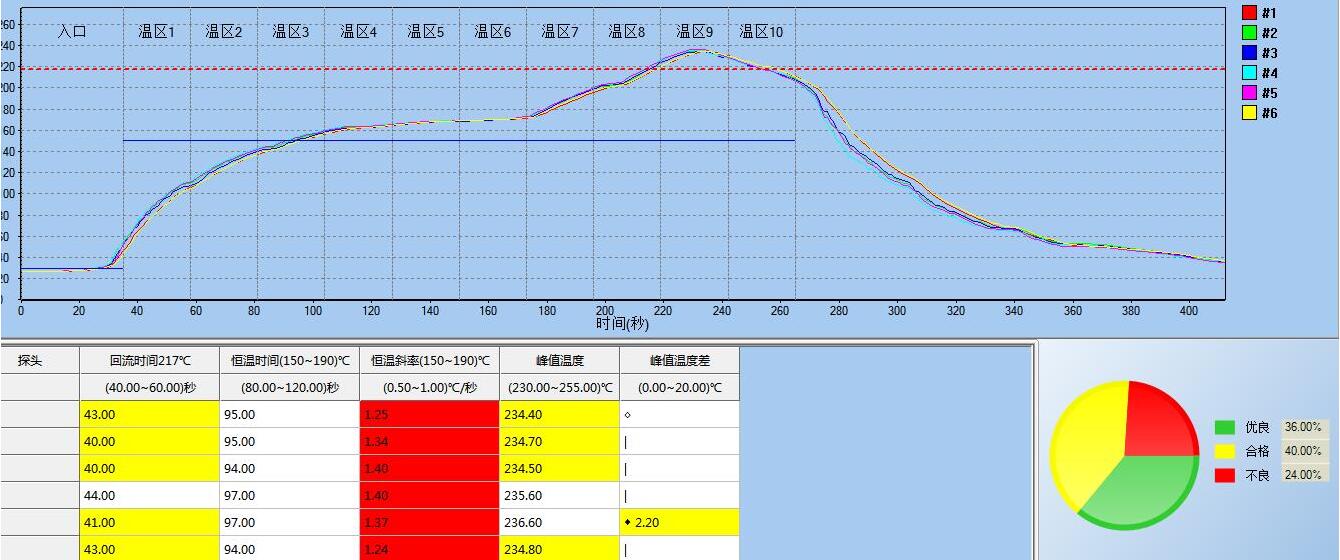

Run the welding equipment, the temperature profile of the welding equipment for data acquisition.Furnace temperature tester data acquisition device is shown in the figure.

Reflow temperature

2.Furnace temperature tester data acquisition device obtained temperature curve data into the furnace temperature tester,using analysis software to analyse the actual temperature curve.If the actual welding temperature profile does not reach the preset result, then correct the temperature profile again.The corrected welding programme will be imported into the welding equipment again.

3.Furnace Temperature Curve Correction: Run the welding equipment again and acquire data on the corrected welding temperature curve. The temperature profile is analysed to see if it overlaps with the ideal temperature profile.

Finally,there is one more point that we must be concerned about,in the SMT processing production,there is also the issue of the cooling zone. Misunderstanding of the cooling zone is that after the board soldering is completed, in order to ensure the stability of the solder joints, cooling solder paste for curing,is to keep the solder joints cold and stable.

However,it is not true that the higher the cooling rate, the better. It should be considered in conjunction with the cooling capacity of the reflow soldering equipment and the thermal shock that the PCB, components and solder joints can withstand. A balance should be struck between ensuring the quality of the solder joints without damaging the PCB and components.The minimum cooling rate should be above 2.5°C and the optimum cooling rate above 3°C.Considering the thermal shock that the components and PCB can withstand,the maximum cooling rate should be controlled at 6-10℃.When choosing the equipment for SMT production,it is better to choose the reflow soldering with water cooling function to get a stronger cooling capacity reserve.