Relay load board is common electrical control components in electronic circuit design and testing. What is a relay? How does it work?

A relay is an electronic control device with a control system (also known as an input circuit) and a controlled system (also known as an output circuit). It is commonly used in automatic control circuits, essentially acting as an "automatic switch" that uses a smaller current to control a larger current. Therefore, it plays roles in automatic adjustment, safety protection, and circuit switching.

Relays are widely used in computer peripheral interface devices, constant temperature systems, temperature regulation, electric furnace heating control, motor control, CNC machinery, remote control systems, industrial automation devices; signal lights, dimming devices, flashers, stage lighting control systems; instruments, medical devices, copiers, automatic washing machines; automatic fire protection, security systems, and as switching devices for power capacitors used in power factor compensation, etc. They are also widely used in chemical plants, coal mines, and other environments requiring explosion-proof, moisture-proof, and corrosion-resistant applications.

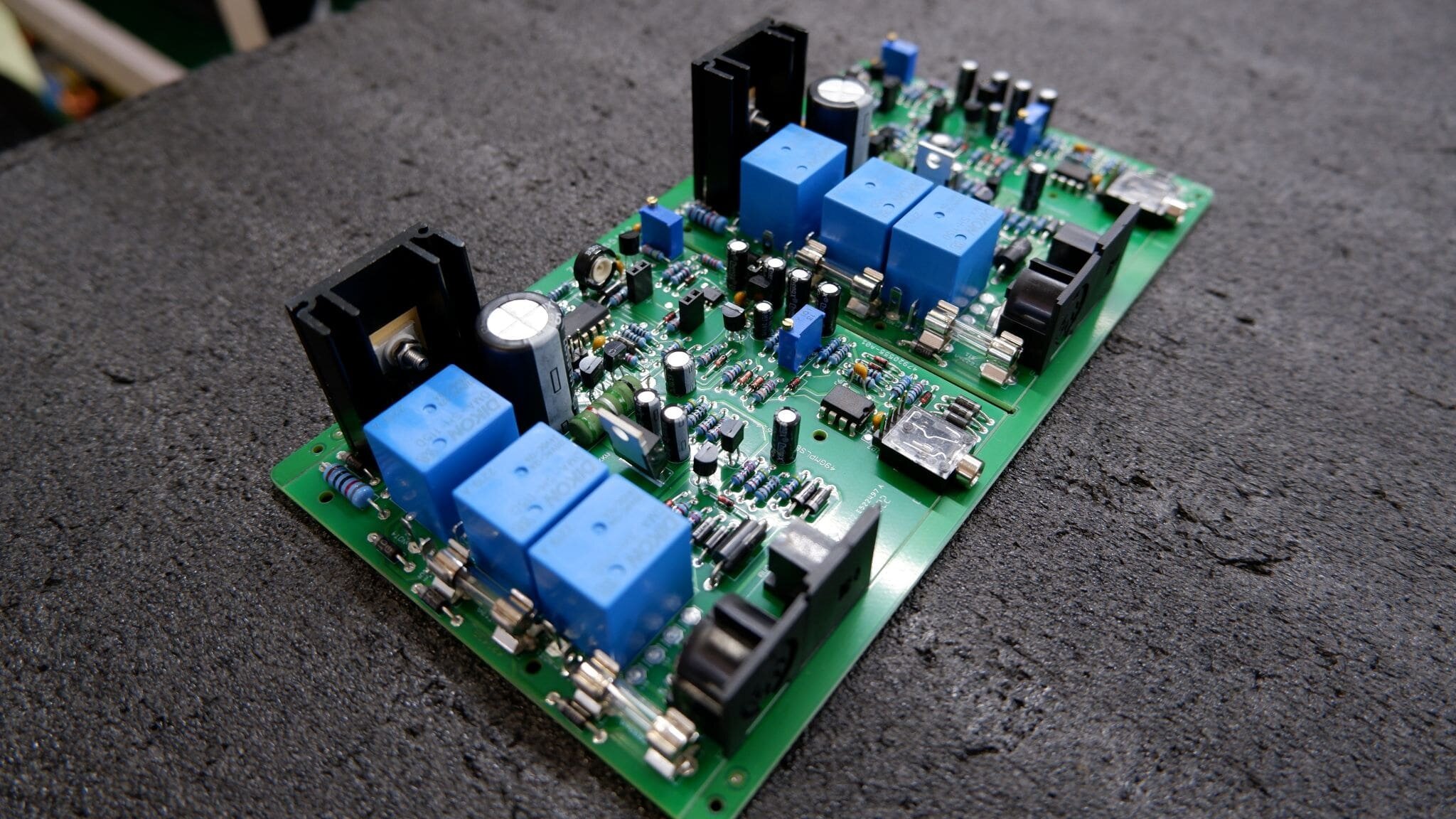

The substrate of a relay load board is usually a PCB, and relays, load components, and control interfaces are connected through wiring and soldering.

In relay load boards, the PCB plays a crucial role in support, interconnection, conductivity, and insulation, ensuring the stable and reliable operation of the entire test circuit.

PCB design affects relay load board performance:

Electrical performance: The copper thickness, trace width, and routing method of the PCB directly affect the current carrying capacity and signal integrity of the load board. For example, high-current relay load boards require wider power lines and increased copper thickness to reduce voltage drop.

Heat dissipation performance: Relays generate heat when switching loads; the PCB material (FR4, ceramic PCB, etc.) and heat dissipation design directly affect temperature rise and reliability.

Mechanical performance: The thickness and rigidity of the PCB determine the stability of the relay load board, especially on multi-channel or high-power boards, where mechanical strength is paramount.

PCB manufacturing process determines the achievable functions of the load board:

PCB layer count: Single-layer boards can meet simple load testing needs, while multi-layer boards can achieve complex circuit control and measurement.

Surface treatment: Processes such as HASL, immersion gold, and immersion silver can improve soldering quality and durability.

Microvias and vias: In multi-relay load boards, microvia and via designs ensure reliable signal and power connections.

PCBs provide the foundation for integration and modularity.

Relay load boards (RLBs) integrate multiple relays, load components, and measurement interfaces onto a single board, enabling multi-channel, high-density designs.

Modular PCB design allows for easy expansion or replacement of different load types, improving testing flexibility.

Relay load board

Design Considerations for Relay Load Boards

When designing an RLB, consider the following factors:

Load Selection: Select the load type based on the relay's rated current, voltage, and the actual application scenario to ensure reliable test results.

Heat Dissipation Design: High-power loads generate significant heat, requiring proper heatsink placement or enhanced ventilation to prevent overheating of resistors or relays.

Protection Circuits: Design appropriate protection circuits for potential surge voltages or reverse currents, such as diode snubber circuits, fuses, or overcurrent protection modules.

Standardized Test Interfaces: Ensure standardized control signal, power input, and measurement output interfaces for easy interface with automated test systems or controllers.

Reliability and Maintainability: Relay load boards should employ reliable soldering and wiring methods and be designed for easy replacement of relays and load components, improving maintenance efficiency.

Relay load boards, as crucial tools for relay testing and verification, play an irreplaceable role in electronic R&D, production testing, and laboratory research. By simulating real loads, providing measurement interfaces, and offering protection circuits, they make relay testing more efficient, safe, and reliable. With the continuous development of electronic technology and the increasing demand for automated testing, relay load board will evolve towards higher integration, intelligence, and modularity, providing electronic engineers with more convenient and accurate testing solutions.