Obtaining consistent and predictable phase from any PCB at higher frequencies is not a trivial or routine task. The phase of the signal from a high-frequency, high-speed PCB depends heavily on the structure of its transmission line and the dielectric constant (Dk) of its circuit materials. Electromagnetic waves travel fastest in any object with the lowest Dk (e.g., air with a Dk of 1.0). As Dk increases, wave propagation slows down, with a corresponding effect on the phase response of the transmitted signal. When the Dk of the propagation medium changes, phase distortion of the waveform occurs because the waveform may accelerate or decelerate in the propagation medium, and the Dk may become lower or higher, respectively.

The Dk of RF materials is usually anisotropic, with different Dk values in the three dimensions (3D) of length, width and thickness (x, y and z). For some types of circuit design, not only must the difference in Dk be considered, but also the effect of Dk on phase already included in the circuit fabrication method. As PCB frequencies increase, especially at microwave and millimetre wave frequencies such as those used in fifth-generation (5G) cellular wireless communication network infrastructure equipment and advanced driver assistance systems (ADAS) in electronically-assisted vehicles, phase stability and predictability will become increasingly important.

What causes the Dk of RF circuit materials to change?

In some cases, the difference in Dk on the PCB is due to material effects (e.g. changes in copper surface roughness). In some cases, the Dk variation is caused by the PCB manufacturing method. Some PCB Dk variations are caused by harsh environments (e.g. higher operating temperatures). By understanding how PCB Dk varies due to material properties, manufacturing methods, environment and even Dk testing methods, Dk variations that translate into PCB phase changes can be better understood and predicted, and hopefully minimised.

Anisotropy is an important component of circuit materials,and the Dk variation characteristics are very similar to the 3D mathematical tensor. Different values of Dk on the three axes result in different fluxes and field strengths in the three directions.Depending on the type of transmission line used in the circuit, the phase of a circuit with a coupled structure can be changed by material anisotropy, and the performance of the circuit depends on its orientation in the circuit material.Typically, the anisotropy of a circuit material varies with thickness and frequency, and materials with lower Dk values have less anisotropy. Material reinforcement can also play a role: circuit materials with glass fibre reinforcement are generally more anisotropic than those without glass reinforcement. When phase is critical and PCB Dk is part of the circuit design modelling, the comparison of Dk values between the two materials should always be made on the same axis.

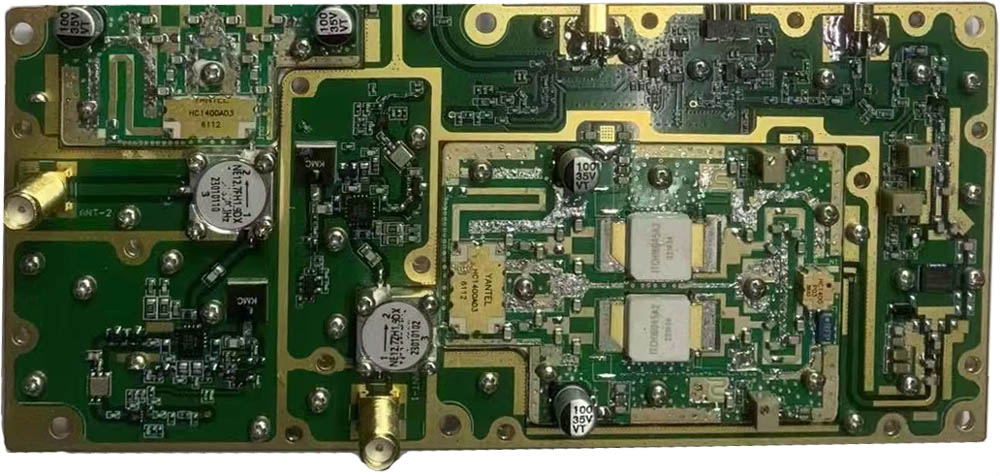

RF Circuit Boards

Designing Dk in Depth

The effective Dk of a circuit is a value based on how EM waves travel through certain types of transmission line circuits. Depending on the transmission line, some EM waves will travel through the combination of conductive metals that form the transmission line, some through the dielectric material of the PCB, and others through the air surrounding the PCB. The Dk value for air (1.00) is lower than for any circuit material, and the effective Dk for commemorative items is the combined Dk value for EM waves travelling through the conductors of the transmission line, in the dielectric material, and partly in the air around the substrate. Design Dk attempts to provide a more practical version of effective Dk and incorporates the effects of different cable technologies, manufacturing methods, conductors and even test methods used to measure Dk. Design Dk is the Dk selected from the material when tested in circuit form and is the appropriate Dk value to use in circuit design and simulation.Design Dk is not the effective Dk of the circuit, but Design Dk uses effective Dk measurements to determine the Dk of the material as shown in the circuit performance.

Variations in different parts of the circuit on a given RF circuit material will result in variations in design Dk.For example, variations in the thickness of the copper forming the circuit conductors mean that the design Dk will be different for each different thickness,and will mean that the phase response of the circuit formed by these conductors will change.The roughness of the copper conductor surface also affects the design Dk and phase response,with smoother copper (e.g. rolled copper) having less effect on the design Dk or phase response than rougher copper.

The thickness of the PCB dielectric material will determine the effect of the surface roughness of the conductor copper on the design Dk and phase response of the circuit. Thicker substrate materials tend to minimise the effect of copper conductor surface roughness, and the design Dk value is closer to the substrate material's intrinsic Dk, even for copper conductors with rougher surfaces.For example,ROGERS' 6.6 mils thick RO4350B circuit material has an average design Dk value of 3.96 for the range of 8 to 40 GHz.For the same material at 30 mils thick,the Dk value for the same frequency range is 3.96,and the Dk value for the same frequency range is 3.96 for the same material. For the same material with a thickness of 30mils, the design Dk value drops to an average of 3.68 for the same frequency range.At twice the thickness (60mils),the design Dk is 3.66, which is the inherent Dk of glass fibre reinforced laminates.

From this example,a thicker circuit substrate can provide a lower Dk design value and the associated advantages.However,in circuits made from thicker substrate materials,especially at millimetre wave frequencies where the signal wavelength is small,it is often more difficult to achieve consistent amplitude and phase at higher frequencies.Higher frequency circuits are more suited to thinner circuit materials where the dielectric portion of the material has less impact on design Dk and circuit performance. Thinner PCB substrates are mainly affected by conductive effects to realise signal loss and phase performance.At millimetre wave frequencies,they are also more sensitive to conductor characteristics (e.g. copper surface roughness) than thicker substrates with respect to the design Dk of the circuit material.

Selecting RF Circuits

At RF/microwave and millimetre wave frequencies,circuit designers rely on several different transmission line technologies,such as microstrip,strip line and ground coplanar waveguide (GCPW) circuits,each requiring different fabrication methods and challenges associated with the advantages.For example,differences in the coupling behaviour of GCPW circuits will affect the design Dk of the circuit.Closely coupled GCPW circuits with tightly spaced transmission lines minimise losses by more efficiently utilising the air between coplanar coupling regions for EM propagation. By using thicker copper conductors,the sidewalls of the coupling conductors are higher and more air in the coupling region is used for EM propagation.This helps to minimise circuit losses,but emphasises the importance of minimising variations in copper conductor thickness.

For a given circuit and circuit material,many factors will affect the design of Dk. Operating temperature will change the design Dk and performance based on the Dk temperature coefficient of the circuit material (TCDk), with lower values indicating less dependence on temperature. High relative humidity (RH) can improve the design Dk of RF circuit materials,especially for highly hygroscopic materials. The characteristics of the RF circuit material as well as factors in the circuit manufacturing process and operating environment all play a role in determining the design Dk of the circuit material.By understanding these effects, they can be minimised.