Choosing the right RF PCB manufacturer for your application is an important decision as it directly affects the quality, cost and lead time of your product. Especially for high frequency and RF applications, choosing an experienced RF PCB manufacturer is especially critical. Here are some key factors that can help you make an informed choice:

Determine requirements:

Before you start selecting a manufacturer, you first need to define your needs.

Product type: Determine the type of PCB you need, such as single-sided, double-sided, or multilayer.For RF PCBs, high layer counts and complex stacking structures are often required.

Size and number of layers: Define the required PCB size and number of layers.

Materials and Finishes: Select the appropriate materials (e.g. Rogers or Taconic) and finishes for the application.This is especially important in RF PCBs, where material properties have a direct impact on the quality of signal transmission.

Quality Standards: Determine the required quality standards, such as IPC-A-600.

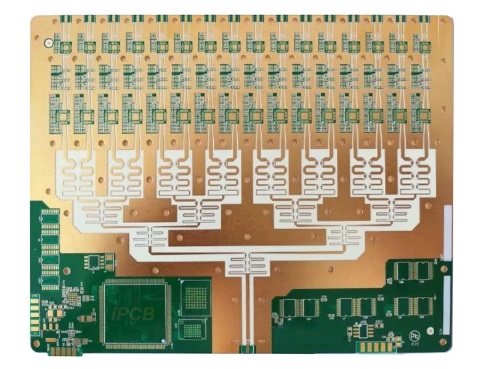

RF PCB

Key factors when selecting a manufacturer:

1. Quality Standards: First, understand the RF PCBmanufacturer's quality control processes and standards. Ask if they follow international standards such as IPC-A-600 or ISO 9001. RF PCB manufacturers often require additional high-frequency test equipment to ensure that the boards perform as required for RF applications.

2. Technical capabilities: Different manufacturers may specialize in different technical areas. For example, some manufacturers may specialize in High Density Interconnect (HDI) boards, whereas for RF PCB manufacturers, they are required to have extensive experience in high frequency signal processing, use of low loss materials and impedance control. In addition, professional RF PCB manufacturers are usually equipped with advanced test equipment, such as network analyzers, to verify RF performance.

3. Production Capability: Understand the RF PCB manufacturer's production scale and capability, including their monthly production volume, maximum board size and minimum lot size requirements. Ensure that they can meet your production needs and can handle complex RF PCB designs such as mixed-compression technology and blind buried hole structures.

4. Lead Time: Lead time is critical to the success of your project. Choose an RF PCB manufacturer that offers fast delivery and make sure they can provide expedited service in the event of an emergency. RF PCBs are relatively complex to manufacture, so it's especially important to choose an RF PCB manufacturer with a proven track record of reliable delivery.

5. Price: Get quotes and compare prices from different RF PCB manufacturers. Although RF PCBs are usually costly, price should not be the only deciding factor, but should be considered in conjunction with quality, service and delivery time.

6. Customer Service: Good customer service ensures that communication is smooth and problems are resolved in a timely manner. Choose a manufacturer that is responsive, familiar with RF PCB applications and easy to communicate with.

7. Sampling: Before deciding to go into mass production, ask the RF PCB manufacturer to provide samples to evaluate their production quality and workmanship. For example, check for compliance with your requirements for insertion loss, return loss, and signal integrity.

8. Environmental considerations: Consider the manufacturer's environmental policies and practices to ensure that they comply with relevant environmental regulations and use environmentally friendly materials and production methods.

9. Geographic location: Consider the manufacturer's geographic location as it can impact lead times and logistics costs. For RF PCB projects, choosing an RF PCB manufacturer with efficient logistics support can reduce potential delays.

10. Reputation and recommendations: Research the RF PCB manufacturer's history and market reputation. When choosing a specialized RF PCB manufacturer, refer to feedback from other HF product customers to see how they have performed on similar projects.

11. Technical support: Choose an RF PCB manufacturer that offers comprehensive technical support and can provide optimization advice during the design phase, such as how to reduce signal interference and optimize impedance control design.

12. Certifications and qualifications: Check if the RF PCB manufacturer has the necessary industry certifications and qualifications, such as UL certification or HF material processing certification, which can be an indicator of their level of expertise.

13. Contract terms: Review contract terms carefully, including price, delivery time, quality assurance, return policy, etc.

14. Long-term cooperation potential: Consider whether the RF PCB manufacturer is suitable for long-term cooperation, their business stability and ability to adapt to market changes. For RF PCB manufacturers, the ability for continuous R&D and technology improvement is critical.

15. Risk Management: Understand the RF PCB manufacturer's risk management strategy to ensure that they are able to cope with supply chain disruptions or other potential issues, such as shortages of critical high-frequency materials.

By taking all of these factors into consideration, you can be more confident in choosing an RF PCB manufacturer that can meet your specific needs. Remember, establishing a good relationship with an RF PCB manufacturer is critical to ensuring the success of your project. A professional RF PCB manufacturer is not just a supplier, it's your partner in high frequency technology.