The RF and microwave PCB industry is growing rapidly, and the push for faster and cheaper production of PCB assemblies continues. This aggressive pace causes PCB design rules to conflict with component requirements. The disconnect between designers and manufacturers leads to blind following of these rules, eliminating opportunities for increased effectiveness.

These issues require designers to be aware of potential problems and pitfalls in order to avoid them. Now we discuss some of the challenges unique to RF and microwave PCB circuit design and some suggestions on how to deal with them, covering everything from basic design tips to practical advice on high-volume RF assembly.

Today we share basic design tips for RF PCB and microwave PCB. Here are some pitfalls in the process to prevent them from happening.

Component placement

Components should be placed as close to the center of the RF and microwave PCB boards as possible. This minimizes parasitic inductance, which can degrade performance at higher frequencies. Components should also be placed as close as possible to their mating connectors. This reduces coupling between traces and improves signal integrity. For example, if you are designing a high-speed digital interface board, it is critical to maintain a minimum distance between traces on opposite sides of the board. This minimizes crosstalk between RF and microwave signals on different layers on the PCB.

Poor grounding

Grounding is a critical aspect of any circuit. If you have any poor grounding in your RF and microwave PCB design, you may end up causing interference with other circuits or even damage your circuit. For example, if your RF and microwave PCB board has traces on both sides, one side may have better connections than the other (due to different environmental conditions). This can cause problems. To avoid this, make sure all traces are well grounded throughout their entire length using multiple vias and thick traces.

Route optimization

Routing paths can be optimized to reduce noise by eliminating vias (interconnect points) in unnecessary areas. Vias are often used as ground planes to help reduce airborne radiation. However, vias can also be used as antennas if they are located near high-impedance points on RF and microwave PCB boards, such as power lines. In this case, they may radiate electromagnetic energy into free space or other nearby conductors, such as traces or cables to a ground plane.

Loop area

Compared to linear traces, loop areas cause signal degradation due to their high impedance. For this reason, use multiple vias instead of a single via whenever possible to minimize loop area, or place them as close as possible to component pads so that they are in contact with the vias that need to be connected to in RF and microwave. Minimum length between component pads on printed circuit board.

Conducting noise

Conducted noise travels through conductive paths, such as traces or ground planes. Conducted noise can be caused by switching transistors, microcontrollers, or other electronic devices on RF and microwave PCB boards. When these devices are turned off, they emit current spikes that create electromagnetic fields that radiate from your RF and microwave PCB boards. These spikes are called transient current spikes, and they can travel through the ground plane on RF and microwave PCB boards, creating an electrostatic discharge (ESD) event if they reach the antenna at the end of the board.

Use multi-layer RF PCB and microwave PCB boards

The more layers you add to an RF and microwave PCB board, the more copper surface area available to dissipate heat and provide a return path for current flow. This means that multilayer boards are ideal for high-frequency applications such as RF/microwave systems, where heat must be efficiently dissipated while maintaining a low-impedance return path for high-frequency currents in the antenna.

Return signal loss

Antenna return signal loss is an important consideration in RF and microwave PCB design. Return loss of any RF and microwave PCB board is defined as the power ratio between the forward wave and the reflected wave at a given frequency. Ideally, this value should be greater than -20 dB at all frequencies of interest. In practice, however, you should consider -10 dB as the minimum requirement for most applications.

The main contributors to return loss include impedance mismatch in the ground plane and leakage current. Impedance mismatches between an antenna and its associated components can cause reflections, resulting in reduced efficiency and reduced effectiveness. For example, ensuring that the impedance match between the antenna and coaxial cable is within +/-2% will help ensure good efficiency.

Leakage currents can also cause considerable losses by reflecting signals back to their source circuits or radiating them into free space, causing interference to other devices or systems on RF and microwave PCBs.

RF PCB laminate characteristics

PCB laminate properties are the basis for RF and microwave PCB board performance. The laminate types available have different properties, including dielectric constant (dk), loss tangent, and temperature coefficient. These factors will affect the performance of your RF and microwave PCB boards throughout their life cycle. These characteristics can be affected by many factors, including the thickness of the PCB material, the type of substrate used, and even the number of layers on the RF and microwave PCB boards themselves.

RO4350B mixed pressure laminated structure

The most important factor when selecting a PCB laminate is ensuring it is compatible with your RF and microwave PCB design requirements. For example, if you require high frequency performance, you may want to choose a high dielectric constant material such as Rogers Core or PTFE laminate. However, if you don't need high frequency performance, a higher dk factor material such as FR4 may be sufficient for your needs.

Transmission lines and vias for RF and Microwave PCBs

Transmission lines are used to conduct radio frequency signals from one place to another. Transmission lines have different impedance values and can be classified based on their electrical length. Impedance is the resistance to electrical flow caused by inductance, capacitance, and other electrical characteristics. Transmission lines usually consist of a single conductor or a pair of conductors (shielded or unshielded). The impedance of a transmission line depends on its physical length and operating frequency.

The main purpose of transmission lines is to reduce signal reflections during conversion between two devices on RF and microwave PCBs. To do this, you must ensure that there are no discontinuities in the line that could cause reflections or standing waves. This requires careful design planning when placing components on your RF and microwave PCB board layout and selecting the correct transmission line design for your application.

There are three types of transmission lines: coaxial cable, microstrip line, and slot line.

Coaxial cable

Coaxial cables are used in high-frequency applications up to 40 GHz because they can handle high currents across the entire bandwidth with little loss. Coaxial cable is typically made from copper wire, but other RF and microwave PCB materials, such as silver-plated copper, can also be used, depending on the frequency band and power requirements of the application.

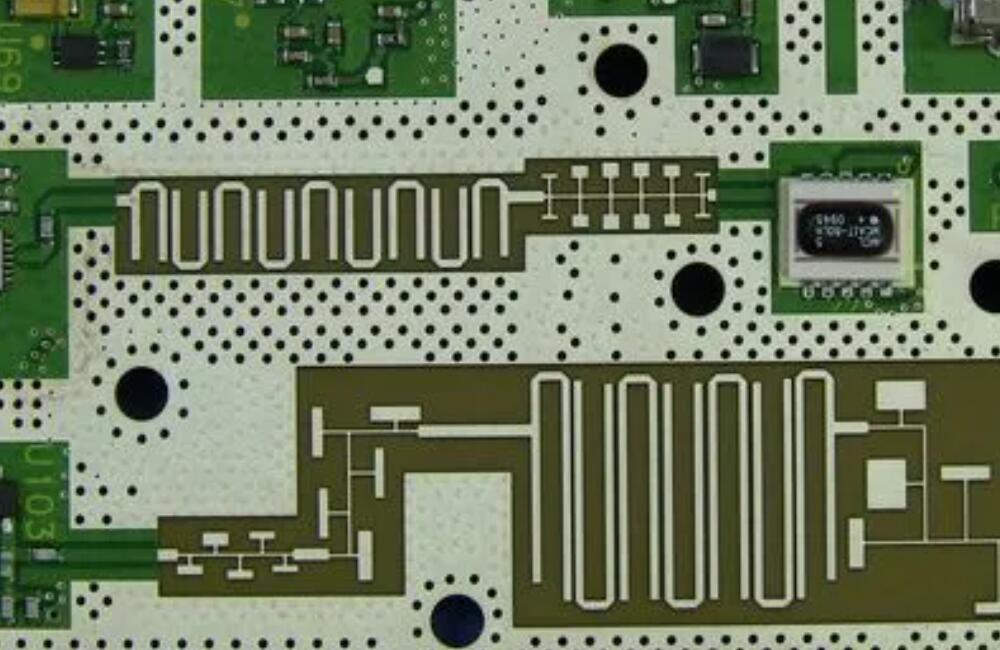

Microstrip

Microstrip is the most commonly used transmission line. It consists of a ground plane on one side of the RF PCB laminateand overhead signal traces on the other side. The ground plane should be wider than the signal traces, so there is no interaction between them. The dielectric layer should be at least 1/4 inch thick for millimeter wave frequencies and 1/2 inch thick for UHF or higher frequencies. At lower frequencies, you can use thinner dielectrics, such as FR-4 or Rogers RO4350B, without adding losses due to fringe fields between the ground plane and the signal traces.

Stripline

Stripline is similar to microstrip except that it does not have a ground plane on one or both sides of the RF PCB laminate. It has less loss than microstrip because there are no fringing fields between the two conductors. Striplines are often used when high-speed signals must be transmitted over long distances without causing impedance mismatches at the bends in the stripline or reflections from the connectors installed at its ends.

Power plane clearance

Power plane gap is the distance between two conductive layers. This gap is designed to reduce undesirable coupling between different signal layers or between signal layers and ground or reference planes. It also limits interference between adjacent traces and prevents crosstalk between adjacent signal layers. It also helps avoid arcing or sparking around sharp corners, which can be dangerous and affect the effectiveness of the circuit.

The minimum recommended clearance for a power layer is 0.15mm from any other signal layer, including vias on the same layer. For example, if there are two signal layers very close to each other, then you should ensure that there is at least 0.15mm between them to avoid any interference issues between them due to the capacitive coupling or inductive coupling effects of nearby vias or traces on these two floors.

Today iPCB provides a general sharing of RF and microwave PCB design and assembly challenges associated with RF and microwave PCB manufacturing. The challenges vary depending on whether you are designing complex RF and microwave PCB boards or working with ultra-small components. While what we cover here is far from comprehensive, hopefully it provides a useful starting point for anyone interested in learning more about RF and microwave PCBs. Follow iPCB to learn more and get started on your next RF and microwave PCB project.