The importance of Rigid-Flexible Laminates (RFLs) has been increasing with the growing rate of introduction of RFLs in electronic products. In the past, rigid-flexible laminates were mostly used in mobile phone batteries, and the market was gradually welcomed by circuit board companies such as Huatong and Xinxing. But in the lens module, display module, true wireless Bluetooth headset, wearable devices and other new applications, more and more rigid-flexible plywood manufacturers are willing to invest. In addition to Taiwan's Yew Wah and Ting Ying, Rigid-Flex plywood manufacturers and many mainland manufacturers have also begun to lay the groundwork.

1.What is FPC?

The birth and development of FPC and PCB gave birth to the new products of rigid-flexible plywood. Therefore, FPC and PCB are flexible circuit boards and rigid circuit boards, which are assembled together through pressing and other processes according to the relevant process requirements to form circuit boards with FPC characteristics and PCB characteristics.

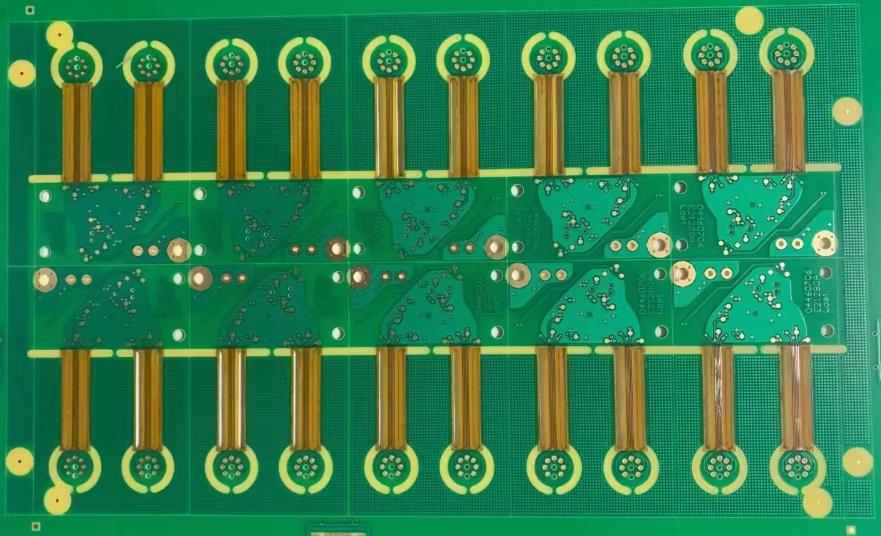

rigid-flex pcb

2.Flexible and rigid plywood classification

If classified according to the soft and hard plywood manufacturing process, the joining method of soft and hard plywood can be divided into two categories of soft and hard plywood and soft and hard plywood. The difference lies in the craftsmanship of flexible and rigid laminates. Flexible and rigid boards can be combined, which is common with blind and buried holes in the design, can achieve higher density circuit design, the technology of rigid-flexible composite boards is to separate the flexible boards and rigid boards, and then they are pressed into a single circuit board. Flex/Rigid-Flex PCBs have signal connections but no through-hole design. However, the commonly used Rigid-Flex PCBs refer to all Rigid-Flex PCB products, without a breakdown of the two.

Rigid-flex PCBs were first used in the field of battery modules. Nowadays, for all mobile phone brands around the world, the use of RIGID-FLEX plywood for batteries has become a consensus, and will probably become a long-term trend. At the same time, in order to accommodate more lenses in an increasingly small space, mobile phone lens modules have also begun to use rigid-flexible plywood. Currently, Korean and Chinese brands of mobile phones using rigid-flexible laminates as the mainstream lens technology. It is also gradually extended to other mobile phone modules such as displays. As for the lightweight and multi-functional features of wearable devices, naturally expected to become a large-scale introduction of rigid-flexible plywood the next application.

In the future, the combination of rigid-flexible plywood in other consumer electronics products will only see more and more opportunities. Some industry insiders have revealed that the Internet of Things products they are seeing now, including smart home appliances such as smart speakers, may have adopted Rigid-Flex plywood in specific functional modules due to their design and cost requirements.