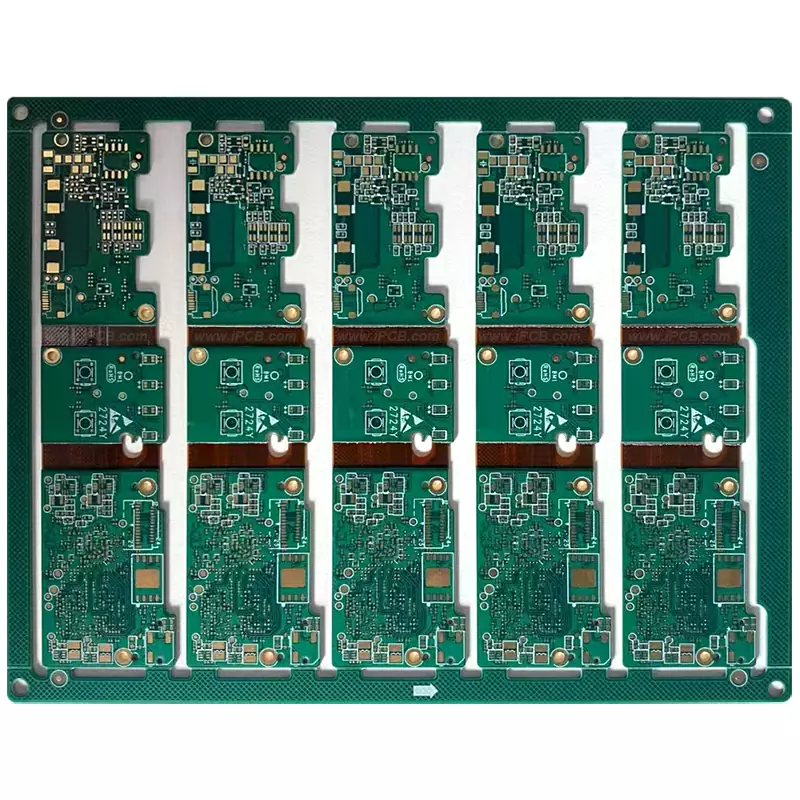

Product Name: Rigid-Flex PCB Connector

Substrate: FR-4+PI

Layer: 6L

Hard board thickness: 0.8mm

Soft board thickness: 0.2mm

Copper plating thickness: 0.025mm

Surface treatment: ENIG

Minimum line width/spacing: 4/4 mil

Product Applications: Connector

Rigid-Flex PCB is an integral part of the entire machine, usually cannot form electronic products and must have external connection issues. For example, electrical connections are required between Rigid-Flex PCBs, between Rigid-Flex PCBs and off board components, and between Rigid-Flex PCBs and equipment panels. Choosing the optimal combination of reliability, technicality, and economy is one of the important aspects of Rigid-Flex PCB design.

Connector connections are commonly used in complex instruments and equipment. This' building block 'structure not only ensures the quality of mass production and reduces system costs, but also provides convenience for debugging and maintenance. When the equipment malfunctions, maintenance personnel do not need to check the component level (i.e. check the cause of the malfunction and trace the specific source of the component. This task requires a lot of time). As long as the board is identified as abnormal, it can be replaced immediately, eliminating faults in the shortest possible time, shortening downtime, and improving equipment utilization. The replaced circuit board can be repaired within sufficient time and used as a spare part after repair.

1. Standard pin connection

This method can be used for external connection of Rigid-Flex PCB, especially in small instruments where pin connections are commonly used. Connect two Rigid-Flex PCBs through standard pins, which are generally parallel or perpendicular, making it easy to achieve mass production.

2. Rigid-Flex PCB connector

This method involves making a plug from the edge of the Rigid-Flex PCB, and designing the plug part according to the size of the socket, the number of contact points, the distance between contact points, and the position of the positioning hole, to match it with a dedicated Rigid-Flex PCB socket.

When manufacturing PCB board, the plug part needs to be gold-plated to improve wear resistance and reduce contact resistance. This method is easy to assemble, has good interchangeability and maintenance performance, and is suitable for standardized mass production. The disadvantage is that the cost of Rigid-Flex PCB increases, and there are higher requirements for the manufacturing accuracy and process of Rigid-Flex PCB; The reliability is slightly poor, often due to poor contact caused by oxidation of the plug or aging of the socket spring. In order to improve the reliability of external connections, the same outgoing line is often connected in parallel through contacts on the same or both sides of the circuit board.

The connection method of Rigid-Flex PCB connectors is commonly used for products with multi board structures. There are two types of connectors for Rigid-Flex PCB or baseboards: spring type and pin type.

Rigid-Flex PCB

Rigid-Flex PCB has many advantages

1. It can effectively save PCB space and reduce the use of connectors or HotBar manufacturing processes,

Due to the integration of Rigid-Flex PCB, it can save space that would otherwise require connectors or HotBar processes. For some PCBs with high-density requirements, one less connector is needed. Space is like finding a treasure. This also saves the cost of parts using connectors or the cost of HotBar process. In addition, by eliminating the need for connectors, the space between the two PCBs can be made more compact.

2. Shorten signal transmission distance, improve speed, and effectively enhance reliability. The traditional signal transmission through connectors is "PCB → connector → FPC → connector → PCB", while the rigid flex PCB, (iPCB's exquisite technology and rich experience. Rigid-Flex PCB, iPCB has been focusing on the FPCB industry for many years and is a professional high-precision Rigid-Flex PCB manufacturer).

The signal transmission of Rigid-Flex PCB is reduced to "PCB → FPC → PCB", and the problem of signal transmission attenuation between different media is also reduced due to the shorter signal transmission distance. The circuits on general PCBs are made of copper, while the contact terminals of connectors are gold-plated and the solder pins are fully tinned, requiring solder paste. When soldered onto a PCB, signal transmission between different media inevitably attenuates. If we switch to Rigid-Flex PCB, these media will be reduced and the signal transmission capability can be relatively improved. For products that require high signal accuracy, it can help improve their reliability.

3. Simplify product assembly and save assembly time. Using Rigid-Flex PCB can reduce the time required for SMT parts, as the number of connectors is reduced. It also reduces the assembly time of the entire machine, as it eliminates the assembly action of inserting FPC into the connector or the manufacturing process of HotBar. It also reduces the cost of parts management and inventory, as BOM has been reduced, resulting in less management.

4. Rigid-Flex PCB has other advantages: it is flexible and versatile, can be 3D wired, and can change shape according to space constraints.

5. Rigid-Flex PCB is resistant to high and low temperatures and flame retardant.

6. Foldable does not affect signal transmission function.

7. Can prevent static interference.

8. Stable chemical changes, good stability, and high reliability.

9. Facilitate the design of related products, reduce assembly time and errors, and increase the service life of related products.

10. Rigid-Flex PCB application product reduces volume and weight significantly

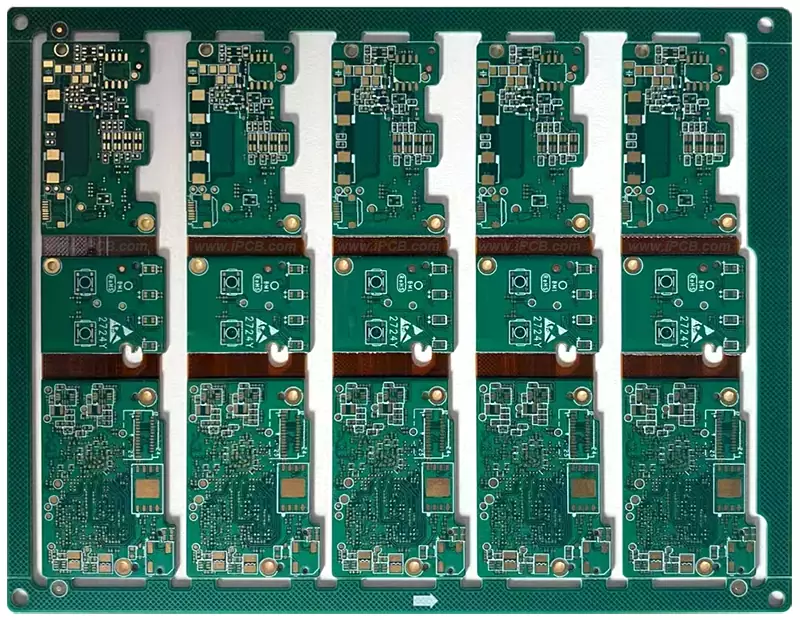

Product Name: Rigid-Flex PCB Connector

Substrate: FR-4+PI

Layer: 6L

Hard board thickness: 0.8mm

Soft board thickness: 0.2mm

Copper plating thickness: 0.025mm

Surface treatment: ENIG

Minimum line width/spacing: 4/4 mil

Product Applications: Connector

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.