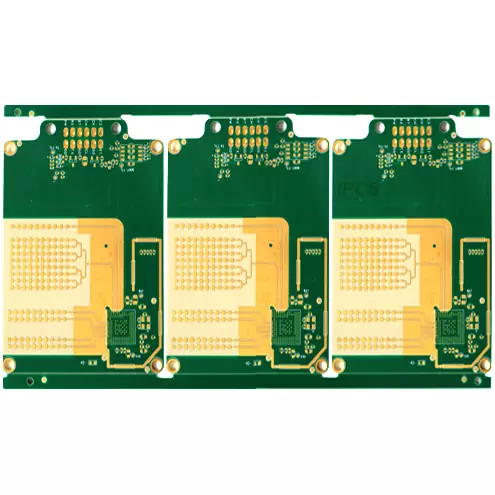

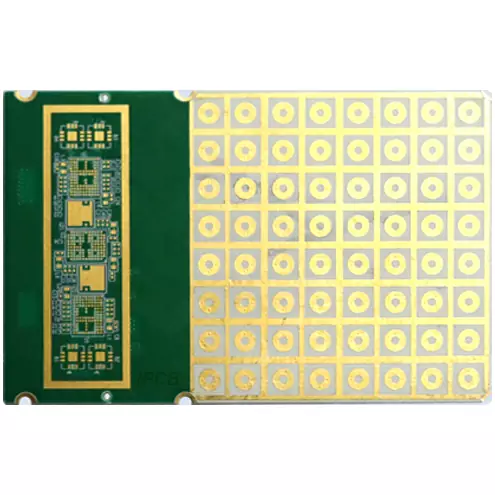

Product: RO3003 PCB

Material: Rogers RO3003

Layer: 2-8Layers

RO3003 Dk: 3.0

RO3003 Df: 5mil (0.127mm)

RO3003 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Solder mask colors: green, red, blue

Surface treatment: silver, gold, osp

Application: radar, instrument

Rogers RO3003 high-frequency PCB board still exhibits excellent dielectric constant (Dk) stability at different temperatures and frequencies. The unique design enhances the stability of RO3003 high-frequency PCB material and eliminates the step change in dielectric constant of general PTFE materials at room temperature. RO3003 is highly suitable for applications such as automotive radar (77 GHz), advanced driver assistance systems (ADAS), and 5G wireless infrastructure (millimeter wave).

RO3003 PCB uses the best resin and special fillers, as well as ED copper material with extremely low copper foil surface roughness (vlp). Its dielectric constants at 10GHz and 77GHz are 3.00 (clamped strip line method) and 3.07 (microstrip differential phase method), respectively. The loss of Ro3003 high-frequency circuit board material is also very low. According to the microstrip line differential length method, the insertion loss at 77GHz on 5mil Ro3003 material is only 1.3dB/inch.

RO3003 features

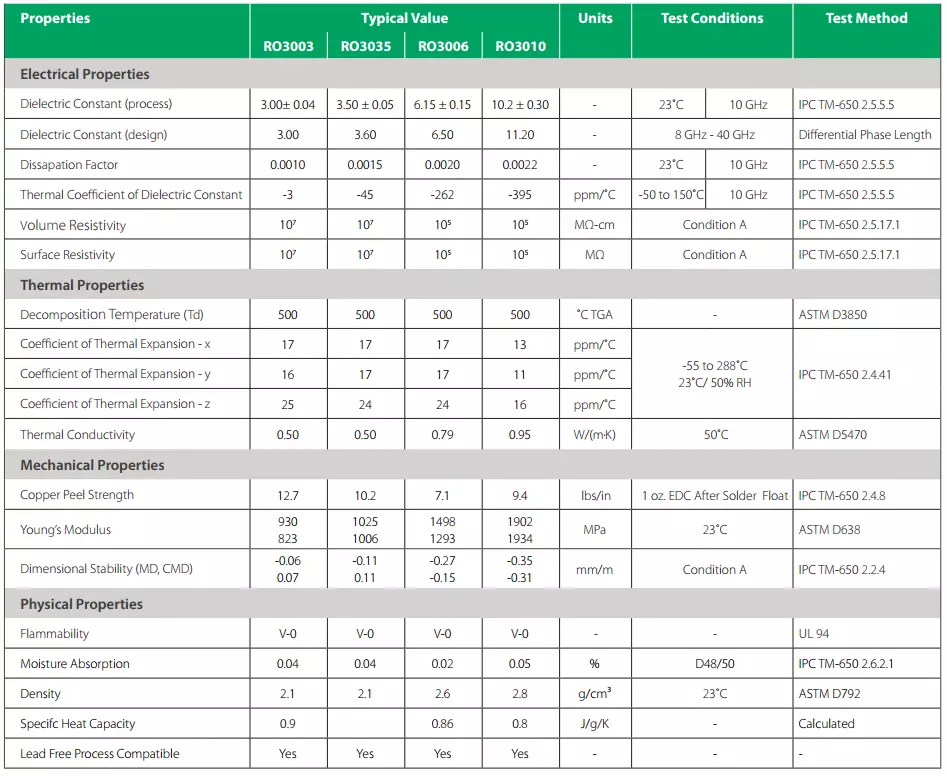

Dk =3.00 +/- .04

Df= 0.0010@10GHz

X. The CTE of the Y and Z axes is low, at 17, 16, and 25 ppm/° C, respectively

Low Dk loss, widely used in 77 GHz radar applications

High cost-effective circuit board manufacturing

Rogers RO3003 Datasheet

In the Rogers RO3000 material series, the initial low Dk of polytetrafluoroethylene (PTFE) is improved by adding ceramic materials and sometimes using woven glass reinforcement materials. Although additives can produce a range of circuit materials with a wide selection of Dk values (from as low as 3 to just above 10), these values are strictly controlled through each circuit board. Through these added materials, the advantages of polytetrafluoroethylene (PTFE) have been enhanced in terms of electrical consistency and mechanical strength, and the strict tolerance of Dk values is quite impressive.

The lowest Dk value belongs to RO3003, and the material's Z-axis measured at 10 GHz has a Dk value of 3.00. The Dk tolerance of the entire material is very significant, with a minimum of ± 0.04, indicating impressive control in manufacturing this material using polytetrafluoroethylene (PTFE) and other material components.

The main material added to RO3003 is ceramic, which results in a slightly higher Dk than the nominal Dk of polytetrafluoroethylene (PTFE). In order to achieve higher mechanical strength, Rogers RO3203 circuit board not only added ceramic materials, but also added glass cloth reinforcement materials. At 10 GHz, the process Dk only slightly increased by 3.02, while maintaining the same strict Dk tolerance of ± 0.04.

The higher the Dk value, the smaller the circuit characteristics for a given signal frequency. The Rogers RO3000 series components support polytetrafluoroethylene (PTFE) with different mixtures of ceramic and woven glass reinforcement materials, providing a Dk value of up to 10. For example, the RO3035 circuit board increases the Dk to 3.50 by adding ceramic material to polytetrafluoroethylene (PTFE) while maintaining a Dk tolerance of ± 0.05. By adding more ceramics or different types of ceramics to polytetrafluoroethylene (PTFE), the RO3006 circuit board increases the process Dk value to 6.15 while maintaining a Dk tolerance of ± 0.15.

The circuit board can also provide mechanical strength enhanced by woven glass, as well as the same Dk value and Dk tolerance as the RO3206 circuit board. The RO3010 circuit board can add a ceramic part of polytetrafluoroethylene (PTFE) composite material to achieve a process Dk of 10.20 and a Dk tolerance of ± 0.30. It can also be reinforced with woven glass and provide the same process Dk of 10.20, but with a slightly lower Dk tolerance of ± 0.50, which is the same as the RO3210 circuit board.

Strictly control the material quantity of each composite material, and even if the Dk value increases, the Dk tolerance will always remain strict. In each case, the quality of individual materials (including basic polytetrafluoroethylene (PTFE) materials) is crucial for achieving composite material Dk values within such a strict window.

For users who prefer a Dk value as close as possible to the basic polytetrafluoroethylene (PTFE) value of about 2, Rogers RT5000 RF circuit materials include RT5870 circuit board with a process Dk value of 2.33 and RT5880 circuit board with a process Dk value of 2.20; The Dk values of both materials are maintained throughout the entire material, with an astonishingly strict tolerance of ± 0.02. These circuit board based on polytetrafluoroethylene (PTFE) use composite materials with different random glass fiber contents to achieve different Dk values.

The composition of high-frequency circuit board materials contributes greatly to their high-frequency performance, but it also affects the processing method of circuit materials during PCB manufacturing. Although RT5870 and RT5880 circuit board can provide Dk values close to polytetrafluoroethylene (PTFE) and excellent performance at the highest frequency, they are not very friendly to circuit manufacturing processes, especially when using low-cost FR-4 circuit materials as a reference for processing. On the other hand, due to the use of composite materials, RO3000 circuit materials based on polytetrafluoroethylene (PTFE) are more compatible with larger batch circuit manufacturing processes.

iPCB is a professional RF Circuit Board manufacturer that can urgently produce high-frequency PCB board, mixed voltage high-frequency board, special circuit board, microwave RF board, microwave antenna board, and other products. Our warehouse has long-term inventory of high-frequency board such as Rogers, Taconic, F4B, TP-2, FR-4, RO3003, etc. We can quickly deliver high-frequency PCB model.

Product: RO3003 PCB

Material: Rogers RO3003

Layer: 2-8Layers

RO3003 Dk: 3.0

RO3003 Df: 5mil (0.127mm)

RO3003 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Solder mask colors: green, red, blue

Surface treatment: silver, gold, osp

Application: radar, instrument

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.