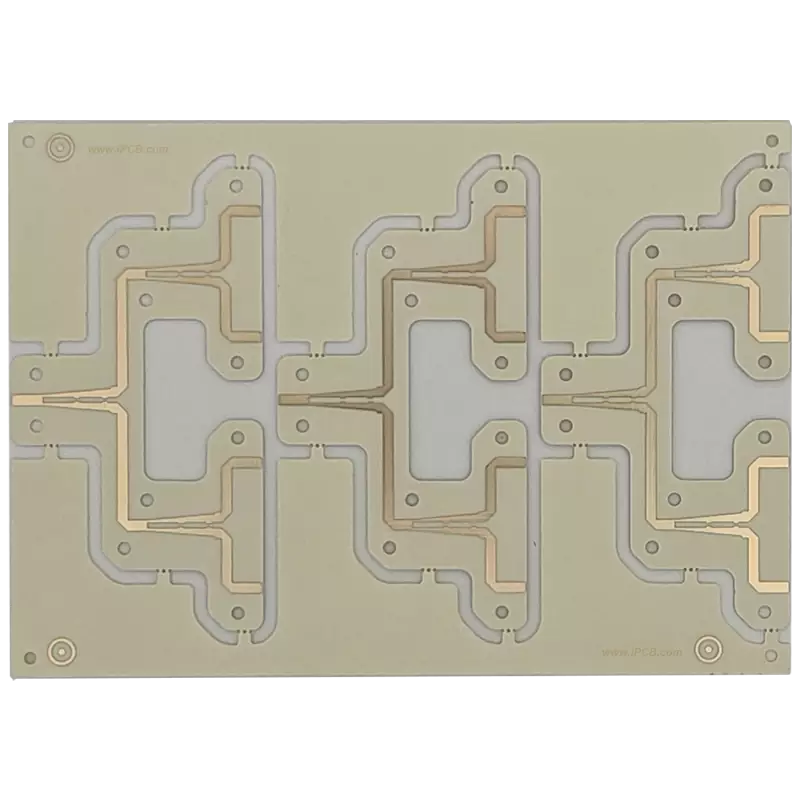

Product: RO4003C PCB

Material: Rogers RO4003C

Dielectric constant: 3.48+/-0.05

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.762mm (30mil)

Finished product thickness: 0.85mm

Solder mask color: None

Screen color: None

Surface treatment: immersion gold

Product application: Communication

Rogers RO4003C model

4450B BOND PLY 14X24 UNPUNCHED SHEET, 4450B BOND PLY 24X20 UNPUNCHED SHEET, RO4003C 24X18 1E 0080+-001/DI, RO4003C 48X36 1E 0320+-002/DI, RO4003C 12X18 1E 0320+-002/DI, RO4003C 12X18 1E 0080+-001/DI, RO4003C 24X18 5TC/5TC 0087+-001/DI, RO4003C 24X18 5E 0080+-001/DI, RO4003C 48X36 5E 0320+-002/DI, RO4003C 48X36 1E 02000+-0015/DI, RO4003C 24X18 5E 0320+-002/DI-RSZ, RO4003C 48X36 1E 0080+-001/DI, RORO4003C hydrocarbon ceramics, RO4003C 24X18 5E 0160+-0015/DI, RO4003C 24X18 1E 0200+-0015/DI, RO4003C 48X36 5E 0200+-0015/DI, RO4003C 24X18 5TC/5TC

Application of RO4003C PCB

Locomotives, rail transit, electricity, renewable energy, body and chassis, lighting, equipment and inverters, defense industrial equipment, onboard, onboard communication, onboard entertainment, vehicle networking, industrial automation, industrial servos, indoor lighting, smart homes, industrial equipment control, mobile phone related, electric vehicle power systems, communication equipment, IoT, warehousing, security systems, global communication systems, high reliability complex multi-layer circuits, wireless communication equipment.

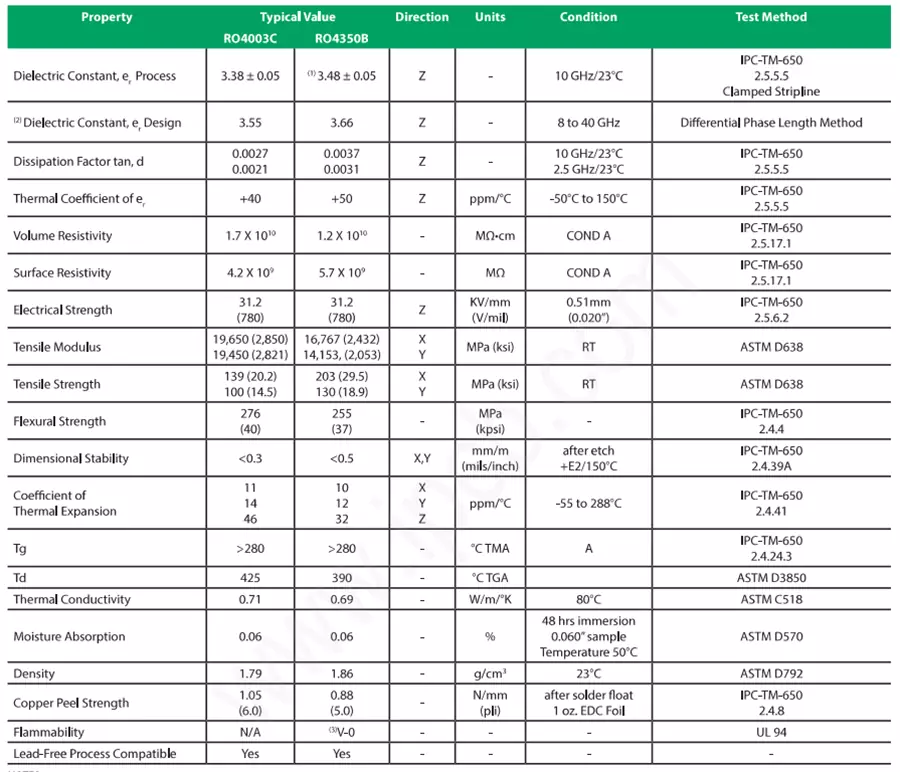

Rogers RO4000 Series DataSheet

Rogers RO4003C material is a proprietary hydrocarbon composite material reinforced with glass cloth and filled with ceramics, which combines the electrical properties of PTFE/glass cloth with the processability of epoxy resin/glass.

Characteristics of RO4003C

Dielectric constant (DK): 3.38 ± 0.05

Loss factor (DF): 0.0027

Z-axis thermal expansion coefficient 46 ppm/° C

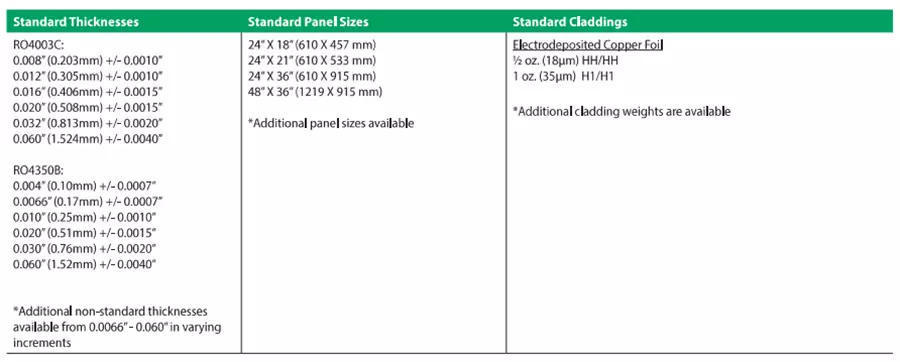

Medium thickness of RO4003C

0.203mm, 0.305mm, 0.406mm, 0.508mm, 0.813mm, 1.524mm

Dimensions of RO4003C material:

12*18inch(305*457mm)

18*24inch(457*610mm)

24*36inch(610*915mm)

36*48(915*1219mm)

Advantages of RO4003C PCB

Very suitable for multi-layer board (MLB) structure

Processing technology similar to FR-4, with lower cost

Designed for performance sensitive high-capacity applications

High cost-effectiveness

RO4003C PCB product features

1. Excellent electrical performance: The electrical performance of Rogers RO4003C is very close to that of PTFE/glass cloth material, with stable dielectric constant and low dielectric loss, which has significant advantages in high-frequency applications. Its dielectric constant fluctuates with temperature almost the lowest among similar materials, and it is also quite stable over a wide frequency range.

2. Excellent processing performance: The processability of Rogers RO4003C is similar to that of epoxy resin/glass cloth materials, and can be processed using standard epoxy resin/glass cloth processing techniques, allowing RF engineers to easily design circuits such as network matching and impedance control of transmission lines.

3. High cost-effectiveness: The price of Rogers RO4003C PCB is much lower than traditional microwave materials, and there is no need for special through-hole pre-treatment or operation procedures, making it highly competitive in price.

4. Stable mechanical performance: Rogers RO4003C PCB has excellent mechanical performance, with a thermal expansion coefficient similar to copper, which can provide excellent dimensional stability and is particularly important for multi-layer circuit design. Even in strict thermal shock applications, the RO4003C can ensure the quality of the through holes inside the board.

RO4003C PCB is suitable for high reliability applications such as aerospace, high-speed PCB, microwave PCB, etc. In addition, due to its unique mechanical properties, it can be processed using standard epoxy resin/glass cloth processing techniques at a much lower cost than traditional RF circuit board.

Product: RO4003C PCB

Material: Rogers RO4003C

Dielectric constant: 3.48+/-0.05

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.762mm (30mil)

Finished product thickness: 0.85mm

Solder mask color: None

Screen color: None

Surface treatment: immersion gold

Product application: Communication

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.