Product: RO4725 RO4730 PCB

Material: RO4725JXR,RO4730JXR,RO4730G3

Dielectric constant: 2.55, 3.0

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 20-60mil

Solder mask color: None

Screen color: None

Surface treatment: immersion gold

Application: High end antenna

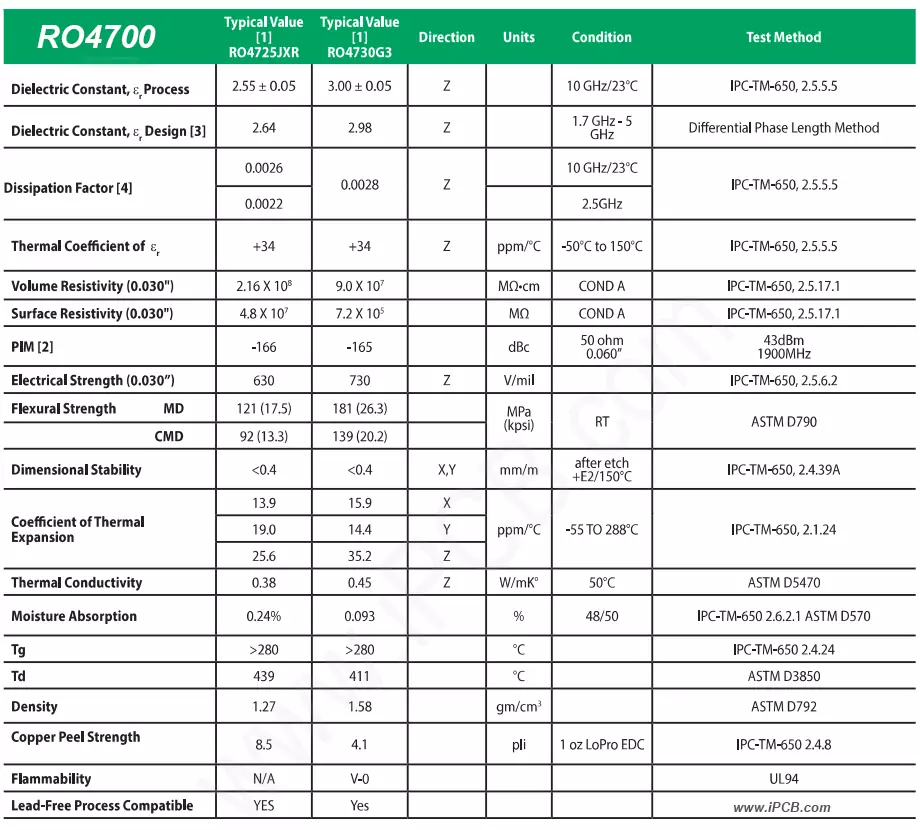

RO4700 series antenna grade RF circuit board is a reliable PCB material, and the RO4725JXR and RO4730G3RF can be used to replace traditional PTFE based RF circuit board.

RO4725JXR and RO4730G3 RF circuit board have the mechanical and electrical performance required by antenna designers. The dielectric constants (Dk) of this series of RF circuit board were tested at 25GHz using LoPr inversion treatment on electrolytic copper foil, with values of 2.55 and 30, respectively, and a loss tangent angle Df of 0.0022. These values can minimize signal loss while allowing PCB antenna designers to achieve significant gain. The RO4700 series RF circuit board material can provide excellent PM performance, with a value of less than -160dBc (measured at an input power of 43dBm for a 1900MHz signal).

RO4700 series antenna grade RF circuit board is compatible with traditional epoxy resin and high-temperature lead-free soldering processes. These RF circuit board do not require traditional special treatments based on PTFE materials, such as pre-treatment of plated through holes. Multilayer RF circuit board can be formed by pressing RO4400 adhesive sheets at 175 ° C. The resin system of the RO4700XR series material is designed to provide PCB antenna designers with the performance they are pursuing. The glass transition temperature of the RO4700XR series materials exceeds 280 ℃ (536 ℉), resulting in a low Z-axis CTE. Additionally, the reliability of plated through holes and the machinability of lead-free soldering are even better.

Advantages of RO4725JXR and RO4730G3

1. Reduce PIM (Passive Intermodulation) - typical value<-164dBc

2. Low insertion loss

3. Suitable for multi-layer compression design (5G antenna)

4. Low PIM value, the RO4730 series has the lowest PIM value among all antenna grade RF circuit board

5. LoPro copper foil brings excellent passive intermodulation (PIM)

6. Improve mechanical hardness relative to PTFE material

RO4700 series models

4725JXR24X181TC/1TC0607+-004/DI, RO4725JXR hydrocarbons/ceramics/glass cloth, 4725JXR48X361TC/1TC0607+-004/DI, 4725JXR48X361TC/1TC0307+-002/DI, 4725JXR24X185TC/5TC0607+-004/DI, RO4700, 4730JXR24X181TC/1TC0607+-004/DI, 4730JXR24X181TC/1TC0307+-002/DI, 4730JXR48X361TC/1TC0607+-004/DI, RO4730JXR hydrocarbons/ceramics/glass cloth, 4730JXR48X361TC/1TC0307+-002/DI, 4730JXR24X181TC/1TC0407+-003/DI RO4725JXR、RO4730JXR

RO4725JXR, RO4730JXR, RO4730G3 Purpose

Locomotives, rail transit, electricity, renewable energy, body and chassis, lighting, equipment and inverters, defense industrial equipment, onboard, onboard communication, onboard entertainment, vehicle networking, industrial automation, industrial servos, indoor lighting, smart homes, industrial equipment control, mobile phone related, electric vehicle power systems, communication equipment, IoT, warehousing, security systems, cellular base station antennas.

RO4725JXR and RO4730G3

In antenna PCB applications, insertion loss is also important, but more importantly, the passive intermodulation index. Rogers' antenna grade RF circuit board RO4725JXR and RO4730JXR have excellent intermodulation performance. At the same time, in certain application scenarios of antenna PCB, a certain degree of hardness or multi-layer board design is also required. The RO4700JXR series board is based on a hydrocarbon resin system, which has sufficient hardness and can be processed and mixed in multiple layers like FR-4 board, making it very suitable for antenna PCB.

The improved RO4700JXR series antenna grade RF circuit board is designed for base stations, RFID, and other antenna PCB, using low loss media and low roughness copper foil to reduce the impact of passive intermodulation (PIM) and achieve low insertion loss. The specially designed RO4700JXR thermosetting resin system uses hollow spherical fillers to achieve a lightweight and low-density RF circuit board, which is about 30% lighter than PTFE material coated with glass fiber.

The RO4725JXR (2.55Dk) and RO4730JXR (3.0DK) RF circuit board also provide a lower cost solution for high-frequency circuit board used in base stations and other antenna PCB.

The RO4700 circuit board has a very low Z-axis coefficient of thermal expansion (CTE, below 30PPM/degree Celsius), which improves design flexibility. The TCDk of the RF circuit board is below 40PPM/degree Celsius, ensuring consistent circuit performance even in the event of short-term temperature changes. Similar to Rogers RO4350B and RO4003C, the RO4700JXR series board has a high glass transition temperature (Tg) exceeding 280 degrees Celsius, meeting lead-free processes and automated mounting requirements.

RO4725JXR, RO4730JXR, and RO4730G3 comply with RoHS standards and are compatible with PCB manufacturing technology and plated through-hole (PTH) processing. Compared to other filling materials, RO4725JXR, RO4730JXR, and RO4730G3 are designed specifically for base stations and other RFID antennas. The halogen-free patented RF circuit board supports longer tool life, thereby reducing manufacturing costs.

Comparison of Several RF Circuit Board Materials

The main difference between RO4725 and RO4730 is the dielectric constant. RO4725JXR has a dielectric constant of 2.55, while RO4730JXR has a dielectric constant of 3.0. They all belong to the same series and use hydrocarbon and ceramic fillers.

The dielectric constant of RO4725JXR is 2.55, and the dielectric constant of the semi cured sheet 4450F is 3.52. If two layers are laminated together, the thickness of the semi cured sheet needs to be two sheets of 4450F with a thickness of 4mil. The thickness with inconsistent dielectric constants can reach 0.2mm, which has a significant impact on the overall antenna performance. Therefore, using the two-layer laminated design of RO4533, the dielectric constant of the RO4533 board is 3.3, which is similar to that of the semi cured sheet 4450F, and can avoid the impact of inconsistent dielectric constants on the antenna PCB performance.

F4B and 4450F are two different resin systems, as F4B is a thermoplastic material and 4450F is a thermosetting material. After compression, residual pore walls and delamination problems are prone to occur Based on the dielectric constant and thickness of F4B, RO4725JXR is used for design, which belongs to the same resin system as 4450F, making it easy to process and ensuring the stability of the antenna PCB.

The dielectric constant of AD255C and RO4725JXR is both 2.55, and their difference is that AD255C is made of polytetrafluoroethylene material with glass cloth, with a loss factor of 0.0011. The board is relatively soft, making it difficult to process. RO4725JXR is a hydrocarbon ceramic filler with a loss factor of 0.0026. The plate is relatively hard and easy to process.

Currently, Rogers has a wide range of products that correspond to different levels of application markets and requirements. The main features of its products are high reliability and consistency. RO4725JXR, RO4730JXR, RO4730G3, AD300C/255C/250C series, etc. Select AD300C, AD255C, and AD250C (flexible substrate) for the mid to high end diversity antenna PCB. RO4725 and RO4730 are recommended for mid to high end antennas, and RO4533 and RO4535 are recommended for mid to low end antennas.

Product: RO4725 RO4730 PCB

Material: RO4725JXR,RO4730JXR,RO4730G3

Dielectric constant: 2.55, 3.0

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 20-60mil

Solder mask color: None

Screen color: None

Surface treatment: immersion gold

Application: High end antenna

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.