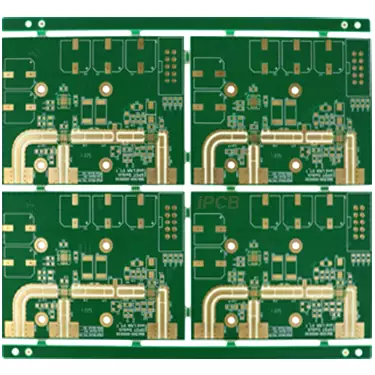

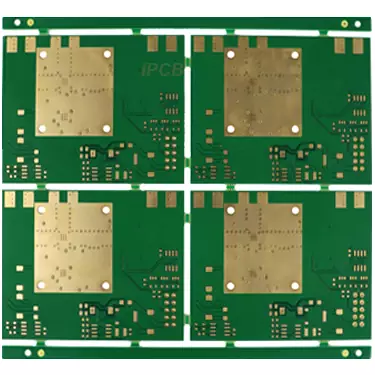

Product: RO4835 PCB

Material: Rogers RO4835 + FR-4

Layer: 6Layers

RO4835 dielectric constant: 3.48

RO4835 medium thickness: 4mil (0.1mm)

RO4835 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 1.2mm

Solder mask colors: green, red, blue

Surface treatment: Immersion gold

Application: Millimeter wave radar

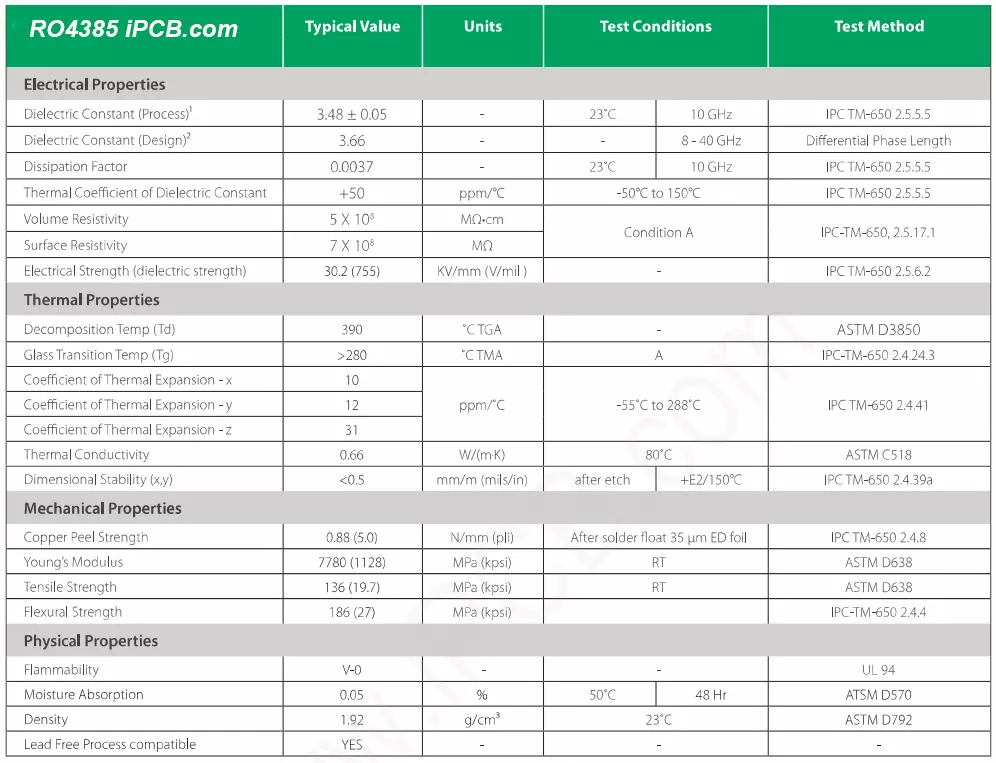

Rogers RO4835 is a high-frequency circuit board material filled with hydrocarbon resin and ceramic, which belongs to civilian products. It has the ability to be compatible with FR4 mixed pressure processing technology and lead-free soldering technology. The dielectric constant of Rogers RO4835 high-frequency circuit board material in the z-direction (thickness direction) is 3.48 at 10GHz, with a tolerance of ± 0.05. The thermal conductivity of this material is 0.69 W/m/° K, and it has excellent dimensional stability in the x-y plane.

RO4835 LoPro high-frequency circuit board is particularly suitable for industrial radar detection applications in short distances (<30m) of 60-81GHz (where excellent electrical characteristics are as important as cost efficiency). The RO4835 LoPro high-frequency circuit board provides both microwave RF and interconnection stability, which are also important indicators of high-frequency circuit board.

Rogers RO4835 can be used in wireless infrastructure, power amplifiers, radar systems, high-speed digital, hybrid vehicles, high-voltage rail transit traction, laser systems, and wind and solar energy conversion fields.

As a supplement to RO4835, RO4835T can be used as the inner circuit core board of multilayer board (MLBs) when thinner high-frequency circuit board are required for their design and processing. The RO4835T high-frequency circuit board has the characteristics of high-performance materials, achieving the best balance between price, performance, and durability, and can be processed and manufactured using standard FR-4 (epoxy resin/glass) technology.

Rogers RO4835 features

Dk=3.48

Using LoPro electrolytic (ED) copper foil

Thermosetting resin system with characteristic open fiber glass fiber cloth

Excellent relative dielectric constant uniformity

Low insertion loss at millimeter wave frequencies

Rogers RO4835 Datasheet

What is the difference between Rogers RO4835 vs Rogers RO4350B PCB?

1. Dielectric constant (Dk) is an important parameter for measuring the polarization ability of PCB materials, which affects the transmission speed of signals in the board. The dielectric constant of Rogers RO4835 is usually around 3.55, while the dielectric constant of RO4350B is about 3.66. This means that the propagation speed of the signal in RO4350B is slightly slower than that in RO4835, which requires consideration of its potential impact on the circuit response rate during design.

2. The loss factor (Df) characterizes the energy loss of materials in electromagnetic fields, which is particularly important for millimeter wave and high-frequency applications. The loss factor of RO4835 is usually better than that of RO4350B, which may result in lower heat dissipation and higher efficiency under high-frequency operating conditions.

3. Rogers RO4835 and Rogers RO4350B PCB also have differences in thermal conductivity. The thermal conductivity of RO4835 is higher than that of RO4350B, which makes it more capable of thermal management when handling high-power applications. Good thermal conductivity helps maintain the thermal stability of PCB board and prevent performance degradation or damage caused by high temperatures.

4. RO4835 is generally considered more suitable for higher frequency applications, such as Ka band radar systems, while RO4350B is widely used in slightly lower frequency communication devices, such as satellite communication.

5. Rogers RO4835 and Rogers RO4350B PCB have shown good performance in mechanical drilling, laser drilling, and electroplating processes, but in terms of chemical corrosion resistance and moisture absorption, RO4835 exhibits better performance, which is crucial for ensuring long-term reliability.

RO4835, due to its incorporation of antioxidants, has an astonishing tenfold increase in antioxidant performance compared to RO4350B, perfectly meeting the stringent requirements of IPC-4103 (substrate specification for high-speed and high-frequency use). However, just as every coin has two sides, the RO4835 may be slightly inferior to the RO4350B in certain performance aspects. For example, its dielectric constant temperature characteristics may decrease, which means it has stricter requirements for the temperature range of the product. In addition, the thermal expansion coefficient of RO4835, especially in the z-axis direction, may also perform poorly, which may lead to a decrease in the relative number of layers of the product. For high-frequency phase characteristics, RO4835 may also be slightly inadequate. Therefore, for products with strict requirements for phase characteristics, it may be necessary to carefully consider whether to choose RO4835.

Rogers RO4835 and RO4350B have significant differences in dielectric constant, loss factor, thermal conductivity, and applicable frequency range. Understanding these differences will help design engineers select the most suitable RF PCB Circuit Board based on specific application and performance requirements, in order to optimize the performance and reliability of circuit design.

Product: RO4835 PCB

Material: Rogers RO4835 + FR-4

Layer: 6Layers

RO4835 dielectric constant: 3.48

RO4835 medium thickness: 4mil (0.1mm)

RO4835 base copper thickness: 0.5oz

Outer copper thickness: 1oz

Finished PCB thickness: 1.2mm

Solder mask colors: green, red, blue

Surface treatment: Immersion gold

Application: Millimeter wave radar

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.