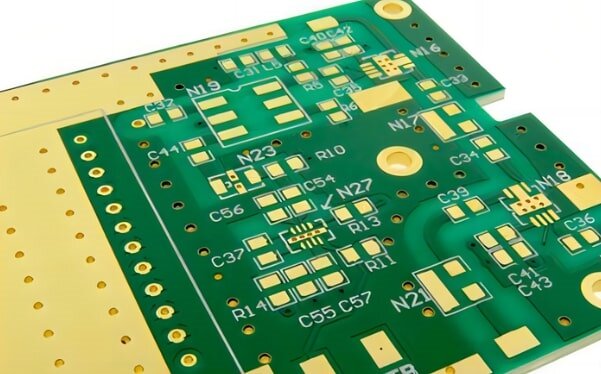

Rogers substrates are used in high-frequency and high-speed fields. Compared with ordinary FR-4 materials, rogers substrate price are generally higher, but they also reflect their superior performance advantages.

What is Rogers PCB?

Rogers PCB maintains stability at high temperatures and minimizes signal loss. Unlike ordinary FR-4 boards, this specialized Rogers PCB material performs well even in harsh environments. It will be your first choice for RF and microwave designs.

The dielectric constant (Dk) of these substrates also remains stable at different frequencies. Therefore, the signals in your high-speed design will be optimally protected. Because they conduct heat more efficiently than FR-4, they are ideal for high-power applications. This gives Rogers the stability you need for difficult builds.

Rogers substrate price

Main factors affecting the price of Rogers circuit boards: The price of Rogers substrates varies depending on the specific model, thickness, copper foil thickness, and purchase quantity.

Material model and specification

High-end models with high Dk and low Df (dielectric loss) are more expensive. For example, the price of RT/duroid 5880 is usually higher than RO4003C.

Board thickness and copper foil thickness

Different thicknesses affect the cost. Common thicknesses are 0.254mm~3.2mm, and copper thicknesses are often 0.5oz, 1oz, 2oz, etc.

Processing difficulty and precision requirements

High-frequency boards usually require higher impedance control, tolerance accuracy, and hole wall processing, which affects the manufacturing process and quotation.

Order quantity and delivery time

Bulk orders or standard delivery time (5~7 working days) have better prices, and expedited orders or small batch trial production will increase costs.

Is it a hybrid board?

Some designs use a "Rogers + FR-4" hybrid structure to balance Rogers substrate price and performance. This hybrid processing is more complicated and also affects the overall quotation.

Types of Rogers PCB laminates

Rogers substrate

Here are some common Rogers PCB laminate types we use.

RO3000

The RO3000 series is suitable for commercial RF and microwave circuits. PTFE ceramic material can minimize signal loss. Its stable mechanical properties help you produce multilayer boards more easily. Signal integrity remains consistent no matter how high the temperature.

RO4000

If you need the best high-frequency PCB material in the industry. Made of a ceramic laminate with hydrocarbons, it provides excellent RF performance with minimal losses. One of its main advantages is that it is easily processed with FR-4 processes. As a result, RF PCB manufacturing becomes simple and cost-effective.

Rogers 3003

Designed for high-frequency applications, it is an ideal material for 5G antennas and the best Rogers PCB material for 77 GHz automotive radar systems.

Rogers 3010

Rogers 3010 is more economical. This ceramic-filled PTFE material provides excellent stability.

Rogers 3006

If your application requires extreme reliability, choose Rogers 3006. It has extremely stable electrical and mechanical properties. Its dielectric constant remains constant over a very wide temperature range. This predictability means that your circuit will perform exactly as designed every time.

Although Rogers substrate price are high, they are an irreplaceable choice for high-end products that pursue signal integrity, low dielectric loss, high-frequency stability, and environmental adaptability.