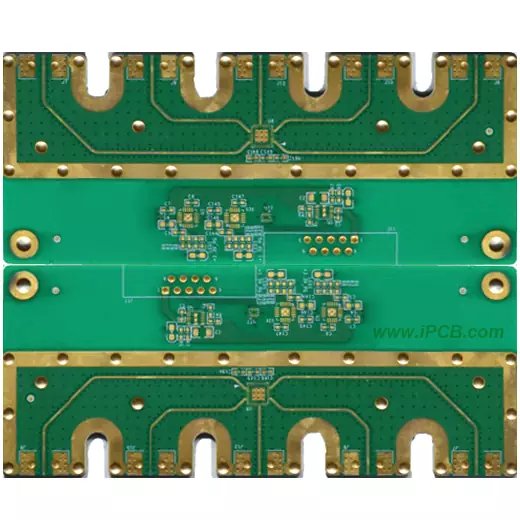

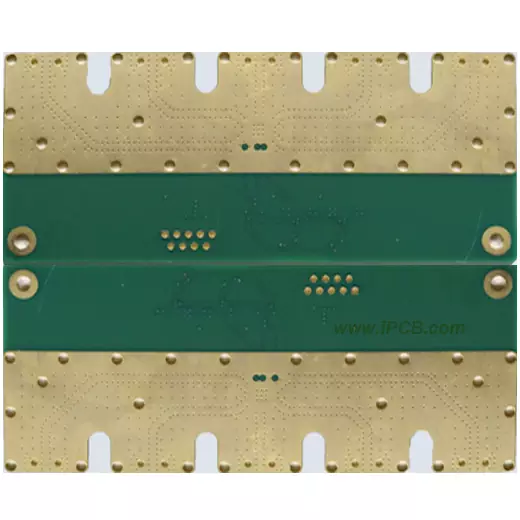

Material: Rogers 5870

Layer: 1L-16L

5870 dk: 2.33

5870 df: 0.0012

Base copper thickness: 0.5oz

Outer copper thickness: 1oz

5880 thickness: 10mil, 20mil, 30mil, 60mil

Solder mask colors: green, red, blue

Surface treatment: Immersion silver, Gold

Application: Microstrip line, radar, missile

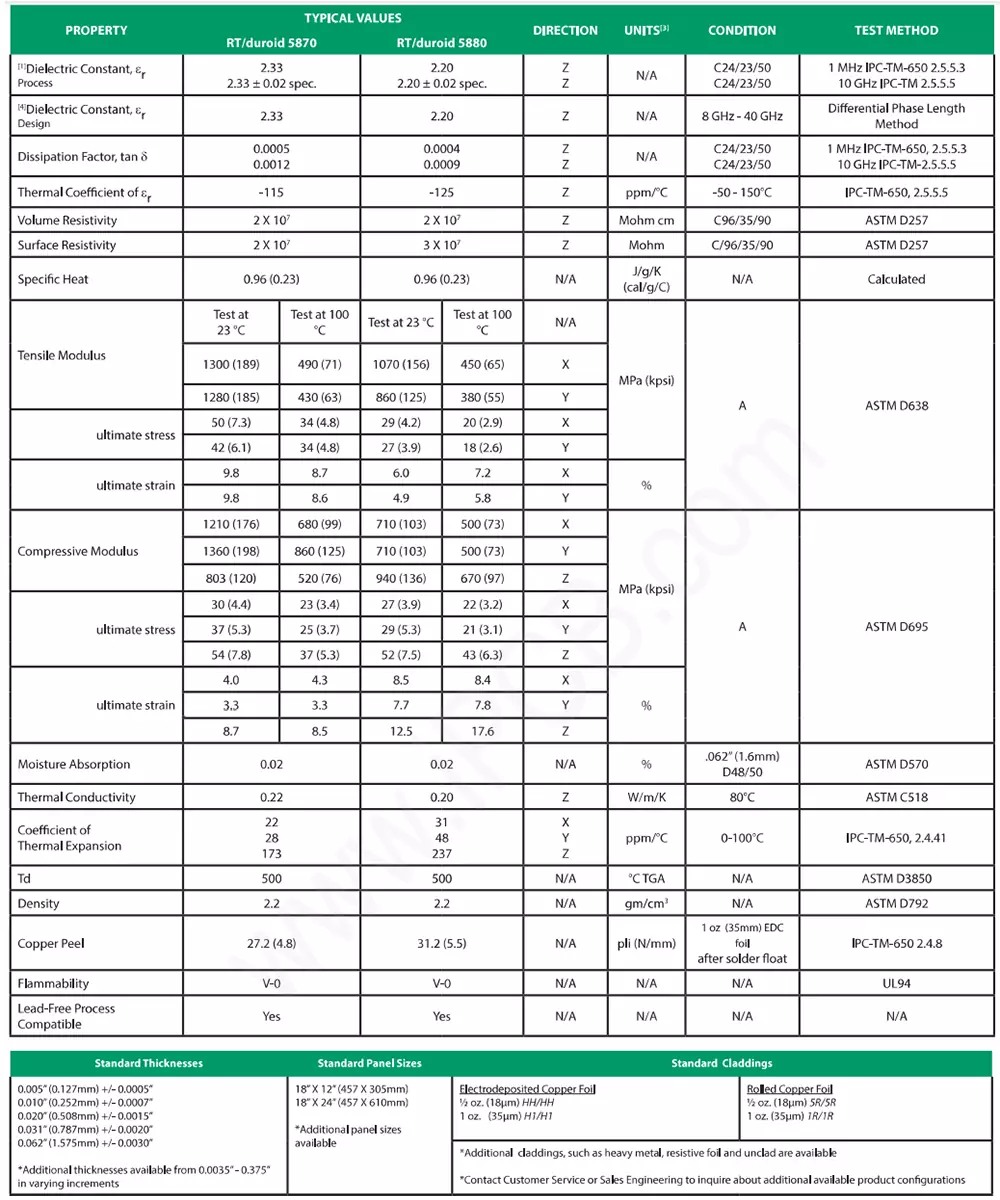

Rogers RT/duroid 5870 and Rogers RT/duroid 5880 are both high-frequency circuit boards made of polytetrafluoroethylene (PTFE) composite material and reinforced with glass microfibers.

The similarities between Rogers 5870 and 5880

Rogers 5870 and 5880 are both composite materials based on PTFE, which have excellent electrical performance and low loss characteristics.

Rogers 5870 and 5880 both use glass microfibers to enhance the mechanical and electrical properties of materials.

Rogers 5870 and 5880 are both suitable for high-frequency, broadband, and applications that require minimal dispersion and loss, such as commercial aviation telephone circuits, microstrip and strip line circuits, millimeter wave applications, military radar systems, missile guidance systems, and point-to-point digital radio antennas.

Rogers 5870 and 5880 are both able to resist solvents and reagents commonly used for etching printed circuit boards or electroplating edges and holes.

The difference between Rogers 5870 and 5880

1. RT/duroid 5880 has a lower dielectric constant than 5870, which makes it have lower signal delay and better performance in high-frequency applications. The dielectric constant of RT/duroid 5880 is 2.20 ± 0.02, while the dielectric constant of RT/duroid 5870 is 2.33 ± 0.02.

2. The dielectric loss factor of RT/duroid 5880 is lower than that of 5870, indicating that it has smaller losses in high-frequency signal transmission. The dielectric loss factor of Rogers 5880 is 0.0009, while the dielectric loss factor of Rogers 5870 is 0.0012.

3. Rogers 5880 and Rogers 5870 have different coefficients of thermal expansion in different axes, which can affect the dimensional stability of the circuit board under temperature changes.

4. Rogers 5880 and Rogers 5870 both have very low water absorption rates, but the specific values differ, which affects the performance of the material in humid environments.

Rogers 5870 and Rogers 5880

When choosing between Rogers 5870 or Rogers 5880, RF circuit board designer need to decide which material to use based on specific application requirements such as signal frequency, transmission rate, cost budget, and space limitations. Both RT 5880 and RT 5870 have their unique advantages and application scenarios, and choosing the right one can significantly improve the performance of the final product.

Material: Rogers 5870

Layer: 1L-16L

5870 dk: 2.33

5870 df: 0.0012

Base copper thickness: 0.5oz

Outer copper thickness: 1oz

5880 thickness: 10mil, 20mil, 30mil, 60mil

Solder mask colors: green, red, blue

Surface treatment: Immersion silver, Gold

Application: Microstrip line, radar, missile

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.