Product: Rogers CuClad PCB

Material: Cuclad Series

Layer: Double-sided and multi-layer

CuClad Dk: 2.17 - 2.5

CuClad Df: 0.0009 - 0.0025

CuClad base copper thickness: 0.5oz

Outer copper thickness: 1oz

Solder mask colors: green, red, blue

Surface treatment: silver, gold, osp

Application: Radar, satellite, instrument

Rogers CuClad high-frequency PCB material is a composite material made of glass fiber cloth and PTFE, which can be used as PCB substrate and antenna cover in high-frequency circuit applications. The dielectric constant (Dk) of CuClad high-frequency PCB material ranges from 2.17 to 2.60. CuClad PCB has the characteristics of low dielectric loss, X-band loss tangent value between 0.0009 and 0.0018, and low moisture absorption rate. Rogers CuClad high-frequency PCB material can provide a maximum size of 36 "x 48".

Rogers CuClad high-frequency PCB includes CuClad 217, CuClad 233, CuClad 250, CuClad 6250, CuClad 6700

CuClad 217

Dk=2.17 or 2.20

Df =0.0009

Using a lower glass fiber/PTFE ratio to achieve the lowest dielectric constant and loss factor among similar products.

Low moisture absorption and low gas release rate

Stable dielectric constant with frequency variation

CuClad 233

Dk = 2.33

Df = 0.0013

By using a moderate ratio of fiberglass to PTFE, a balance can be achieved between reducing the dielectric constant and improving the loss factor, without affecting the mechanical properties.

CuClad 233 uses a staggered woven fabric structure for better dimensional stability while balancing electrical and mechanical properties.

CuClad 250

Dk = 2.40 - 2.60

Df = 0.0018

Using a higher ratio of fiberglass to PTFE can provide mechanical properties similar to traditional substrates.

CuClad 250 provides better dimensional stability and lower thermal expansion characteristics in all directions.

CuClad 6250

Dk = 2.32

Df = 0.0015

Thickness of 0.0015 "(. 038mm)

CuClad 6250 is an ethylene acrylic thermoplastic copolymer that can be used for low-temperature and low-pressure bonding of PTFE/glass materials. CuClad 6250 offers 24 "(610 mm) roll or sheet sizes.

CuClad 6700

Dk =2.35

Df = 0.0025

Thickness of 0.0015 "(0.038 mm) and 0.003" (. 076 mm)

CuClad 6700 is a thermoplastic copolymer of trichlorofluoroethylene (CTFE). Recommended for bonding PTFE (polytetrafluoroethylene) substrates in microwave ribbon line structures and other multilayer board circuits. It can also be used for bonding other structural and electrical components. CuClad 6700 is available in 24 "(610 mm) roll and sheet sizes.

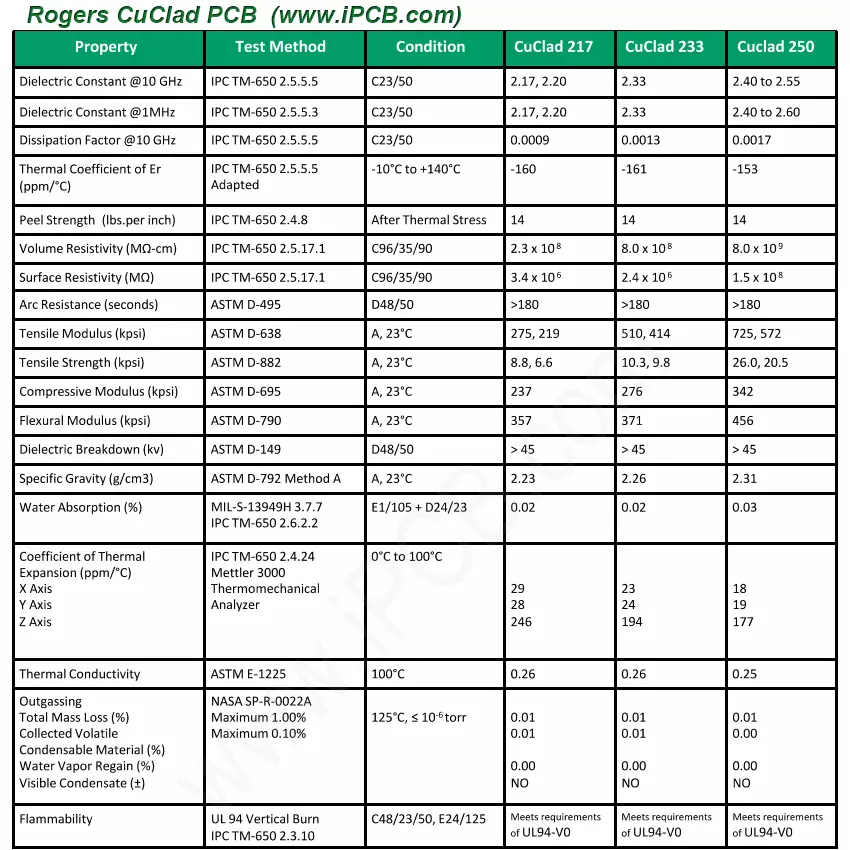

Rogers CuClad SheetData

CuClad Series - CuClad 217, CuClad 233, CuClad 250 are very unique high-frequency circuit boards. The cross layered structure makes the electrical and mechanical properties isotropic in the plane, achieving a good balance between electrical and mechanical properties. CuClad 217, CuClad 233, CuClad 250 use glass woven fabric with strictly controlled PTFE content to provide low dielectric constant values, resulting in wider wires and effectively reducing insertion loss. Suitable for aviation, satellite equipment and other equipment that require strict requirements (CuClad 233's planar CTE matches aluminum used in aircraft surfaces and structures).

Product: Rogers CuClad PCB

Material: Cuclad Series

Layer: Double-sided and multi-layer

CuClad Dk: 2.17 - 2.5

CuClad Df: 0.0009 - 0.0025

CuClad base copper thickness: 0.5oz

Outer copper thickness: 1oz

Solder mask colors: green, red, blue

Surface treatment: silver, gold, osp

Application: Radar, satellite, instrument

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.