Rogers High Frequency Board is a circuit board material specialized for RF microwave applications and is manufactured by Rogers Corporation. This material is designed to handle high frequency signals with extremely low dielectric loss and excellent dielectric constant stability. This is critical to ensure signal integrity and minimize transmission delays. Key features include:

1.Low loss: Rogers sheets provide low dielectric loss, reducing the energy loss of signals during transmission.

2.Stable dielectric constant: Stability of the dielectric constant over a wide range of temperatures and frequencies is critical to maintaining circuit performance.

3.High Thermal Conductivity: Rogers boards typically have high thermal conductivity, which aids in the diffusion of heat, thereby protecting the circuitry from overheating.

RF microwave circuit boards are circuit boards used to process RF microwave signals, and their design and material selection have a direct impact on circuit performance. Rogers High Frequency Board typically need to be manufactured with materials that have low loss and low dielectric constant to ensure signal integrity and speed.

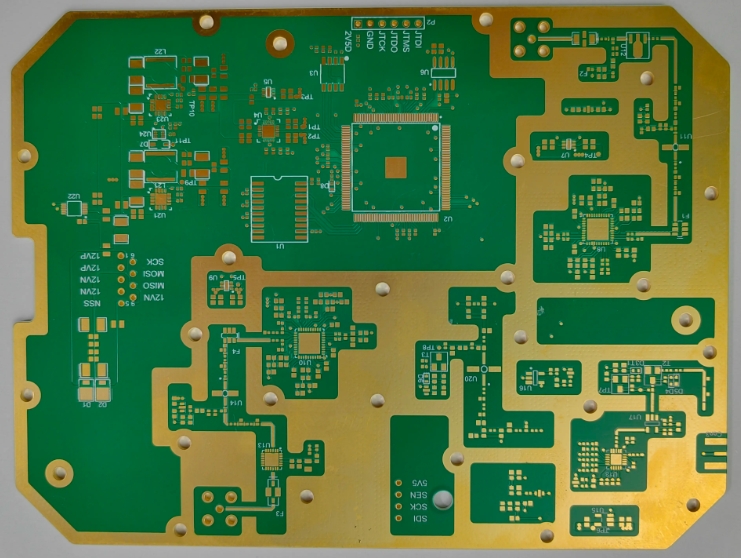

High Frequency Board

A metal substrate is a circuit board that uses a metallic material as a base, common metals include aluminum and copper. Characteristics of metal substrates include:

1.Excellent thermal conductivity: metal substrates conduct heat quickly, making them suitable for the heat dissipation needs of high-power electronic components.

2.High structural strength: Metal substrates have higher mechanical strength and better rigidity than typical fiberglass circuit boards.

3.Electromagnetic shielding: Metal substrates provide natural electromagnetic shielding and reduce electromagnetic interference.

In terms of applications,Rogers High Frequency boards/RF microwave boards are particularly suitable for satellite communications,radar systems,wireless networks and high-speed digital circuits due to their electromagnetic properties. Metal substrates, on the other hand, are more suitable for application scenarios such as automotive,power management,LED lighting and high power amplifiers,where good thermal management is required.

In terms of performance comparisons, Rogers High Frequency pcb/RF microwave boards and metal substrates each have their own strengths.Rogers High Frequency boards excel at handling high frequency signals,while metal substrates are better at handling high power and dissipating heat. Therefore, when selecting a circuit board material, engineers must decide which material to use based on the specific needs of the application.

Whether it's Rogers High Frequency boards/RF microwave boards or metal substrates,they all play a critical role in the performance and reliability of modern electronic systems.Proper material selection can significantly enhance the performance and extend the life of a product. As technology continues to advance,we can anticipate that these high performance circuit board materials will continue to play a key role in the communications and electronics industries.