Material: Rogers RF material

Dielectric constant: 2.17-10.2

Base copper thickness: 18um-70um

Finished copper thickness: 35um-70um

Medium thickness: 5mil-62mil

Finished product thickness: 0.127-1.6mm

Solder mask color: customized

Screen color: customized

Surface treatment: Glod, OSP, Silver

Product application: RF Communication

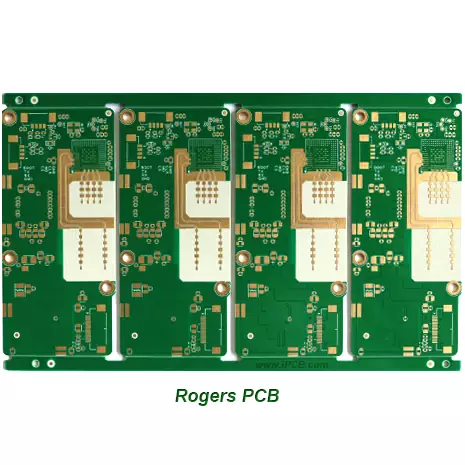

In electronic manufacturing, various PCB boards are encountered, one of which is Rogers PCB, which is widely used in high-end electronics such as high-speed signal transmission, microwave antennas, and RF products due to its superior performance and material properties. Rogers is a partner with excellent agility and reliability, proactive and keeping up with the rapid development of technology.

Rogers PCB high-frequency board is different from conventional FR4 PCB board. Rogers PCB has superior dielectric constant and temperature stability. Its dielectric constant thermal expansion coefficient is very consistent with copper foil, which can improve the shortcomings of FR4 PCB board. It is very suitable for high-speed electronic design, commercial microwave, and RF applications. Its low water absorption rate is very suitable for high humidity applications.

Advantages of Rogers PCB

1. Rogers PCB adopts ceramic or special polymer composite materials, without epoxy resin, thus having lower dielectric constant (DK) and dielectric loss, as well as excellent temperature stability. These characteristics make Rogers PCB perform particularly well in high-frequency environments.

2. Rogers PCB has high precision in thickness control, strong adhesion of copper sheets, excellent heat dissipation performance, no delamination or blistering, ensuring the long-term stability and reliability of the PCB.

3. Rogers PCB is suitable for high-speed PCB design, commercial microwave antennas, RF products, and aerospace industries that require high reliability.

What is the difference between Rogers PCB vs FR-4 PCB?

1. Material composition Rogers PCB uses ceramic or special polymer materials, while FR-4 is mainly composed of epoxy resin and glass fiber. Rogers materials have superior dielectric properties and are suitable for high-frequency applications.

2. The DK value of Rogers PCB is lower and stable with frequency variation, which helps reduce reflection and loss in signal transmission. The DK value of FR-4 is higher and varies greatly with frequency.

3. Rogers PCB has excellent temperature stability and is suitable for working in a wide temperature range. FR-4 performance may decrease in high temperature environments.

4. Rogers PCB has extremely low water absorption and is suitable for high humidity environments, while FR-4 is relatively easy to absorb water and may affect electrical performance.

5. Although Rogers PCB has a high material cost, it is particularly suitable for fields with extremely high performance requirements due to its excellent performance. FR-4 on the other hand, is widely used in the manufacturing of general electronic products due to its lower cost.

6. However, the processing technology of Rogers PCB is somewhat compatible with FR-4 PCB, providing manufacturers with more options.

Rogers PCB Material

What are the products of Rogers PCB?

3000 series (PTFE+ceramic/PTFE+ceramic glass fiber, DK=3.0-10.2): RO3003, RO3003G2, RO3035, RO3006, RO3010, RO3203, RO3206, RO3210

4000 series (hydrocarbons+polytetrafluoroethylene, DK=3.38-6.15): RO4350B, RO4003C, RO4835, RO4360G2

(Hydrocarbons+Polytetrafluoroethylene+Ceramic Glass Fiber, DK=3.3-3.5): RO4533, RO4534, RO4535, RO4725JXR, RO4730JXR, RO4730G3

5000 series (glass fiber+polytetrafluoroethylene, DK=1.96-2.33): RT5880, RT5880LZ, RT5870

6000 series is suitable for electronic circuits and microwave circuits that require high dielectric constants.

(PTFE+ceramic, DK=2.94-10.2): RT6002, RT6202

TMM series (hydrocarbons+ceramics, DK=3.27-12.85): TMM3, TMM4, TMM10, TMM10i, TMM13i

Other: Kappa 438

Prepreg materials: RO4450B, RO4450F

Adhesive film: 2929, 3001, ULTRALAM3908

iPCB is a PCB manufacturer specializing in Rogers PCB, which can meet various high-frequency PCB board needs of customers. iPCB has different specifications of materials such as RO4003C, RO3003, RO4350B, RT5880, RT5870, RO4450F Prepreg, etc., which can meet your immediate response PCB needs. We have rich experience in RFID data process engineering and a complete high-frequency material processing control system to ensure product design functionality.

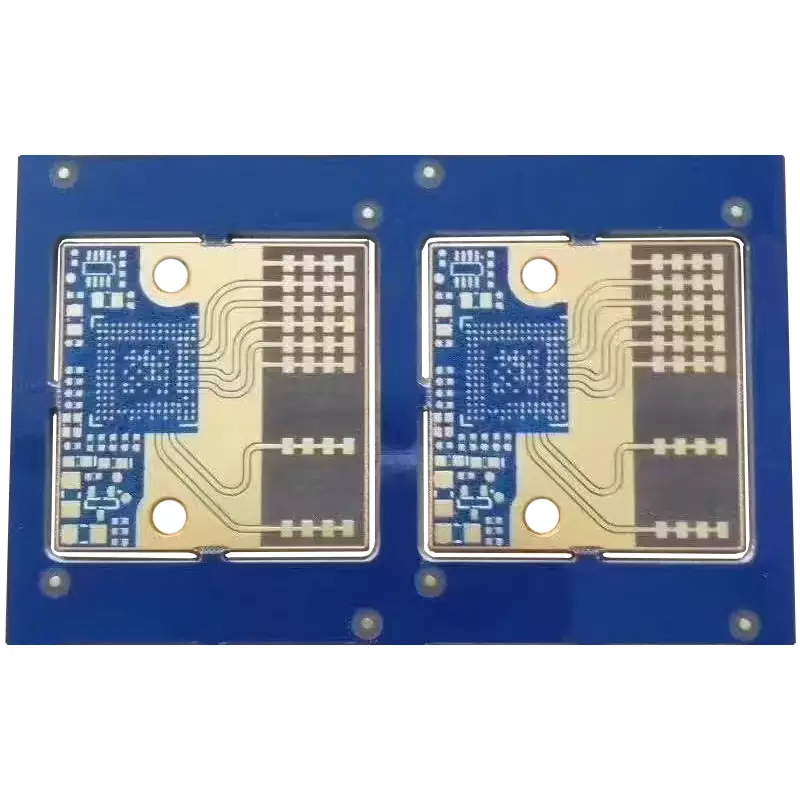

Material: Rogers RF material

Dielectric constant: 2.17-10.2

Base copper thickness: 18um-70um

Finished copper thickness: 35um-70um

Medium thickness: 5mil-62mil

Finished product thickness: 0.127-1.6mm

Solder mask color: customized

Screen color: customized

Surface treatment: Glod, OSP, Silver

Product application: RF Communication

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.