PCBs are widely used in all electronic devices. Different PCBs are made from a variety of materials. Among the many PCB material brands, rogers pcb board material is a preferred material for high-frequency, high-speed PCB design due to its excellent electrical performance, good processing adaptability, and wide range of applications. Rogers PCB board material primarily includes ceramic-filled PTFE (polytetrafluoroethylene) composites, glass-reinforced hydrocarbon/ceramic composites, and the RT series materials, characterized by a low dielectric constant. Unlike traditional FR-4 materials, these materials offer improved dielectric properties, signal integrity, and dimensional stability, making them particularly suitable for high-frequency radio frequency (RF) and microwave applications such as radar, antennas, and cellular communications.

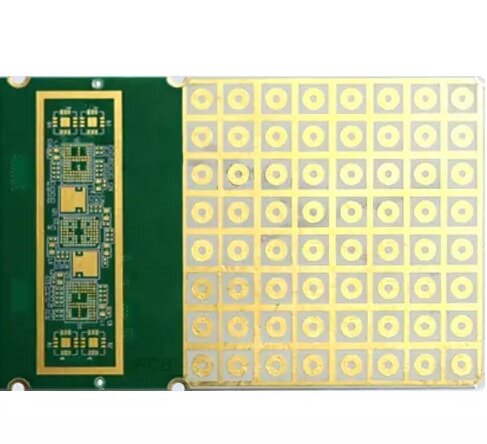

rogers pcb board material

What is rogers pcb board material?

Rogers Corporation is a leading global high-performance engineered materials company headquartered in the United States. Founded in 1832, it has a nearly 200-year history of materials research and development. Its Electronic Solutions division specializes in the development and manufacture of high-frequency PCB materials, offering a variety of circuit board substrates, including the RO4000 series, RO3000 series, TMM series, and RT/Duroid series. Elements in PCB Materials.

Most PCB materials are composed of copper and dielectric. Copper is used to etch conductors or traces. Copper foil types include roll-annealed, reverse-treated, and electrodeposited. Dielectric is an insulating material with various properties, such as Df, Tg, and Dk. It is crucial that it is compatible with copper. According to IPC standards, different material types have different requirements:

PCB Material Types: IPC Standards

Rigid PCBs and Multilayer PCBs: IPC-4101

Flexible PCBs: IPC-4202

High-Speed and High-Frequency Applications: IPC-4103

Flexible PCB Materials and Adhesive Films: IPC-4203

Advantages over Traditional FR-4 Materials

Excellent Dielectric Properties:

Rogers PCB material has lower dielectric loss (Df), meaning less energy is lost during signal transmission, meeting the stringent requirements of high-frequency signal transmission.

Stable Dielectric Constant (Dk):

The Dk value exhibits minimal variation across frequency and temperature, improving signal stability and circuit reliability. Improved Dimensional Stability:

The excellent match with copper foil and low thermal expansion coefficient improve plated through-hole (PTH) reliability and facilitate the integration of components such as ceramic chip carriers.

Excellent Signal Integrity:

The fine microstructure and smooth copper surface help improve signal speed and quality, especially in high-speed PCB designs.

rogers pcb board material

Rogers pcb board material Widely Used in the Market

Rogers Corporation is a leading producer of RF and microwave PCB materials. Rogers pcb board material are primarily characterized by their excellent performance in microwave and RF applications. Their products are widely used in many fields, including automotive, telecommunications, medical, wireless, aerospace, and portable devices. Here we discuss some of the most widely used types.

Rogers 4350B: Laminates made with this material offer tightly controlled dielectric constants and low dielectric losses. These materials are used in g= high-power laminates and have a UL 94 V-0 rating. With a Dk of 3.66 and optimal performance in the 8 to 40 GHz frequency range, they can be used in cell site antennas and microwave links. Rogers 4003C: Rogers 4003C offers a consistent dielectric constant across the entire PCB, as fiberglass/epoxy-glass or traditional microwave laminates are the base materials, but these materials require special processing with through-holes and handling processes. These PCBs utilize RF tags and, due to the material's Dk of approximately 3.55, automotive-grade radar and sensors.

Rogers 3003: Its highly stable dielectric constant and low dissipation factor make it well-suited for RF PCBs. High-frequency radar applications operating near 77 GHz, 6G wireless applications, and driver assistance products can be designed using this material.

Rogers RT Series: These materials are used in multilayer microwave applications due to their low dielectric constant and minimal losses. They are used in missile guidance systems and military radar systems, which require a low dielectric constant (Dk) of 2.20. Rogers RT comes in two varieties: Duroid 6002 and Duriod 5880. They all feature low dielectric constants and low dielectric loss, enabling exceptional precision in printed circuit board performance.

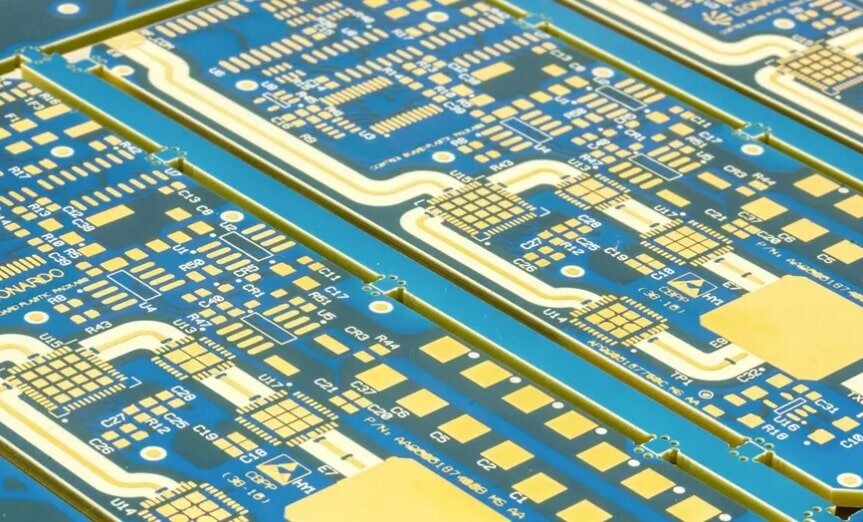

RO4000 Series: RO4000 Series boards are high-performance PCB materials from Rogers Corporation, particularly suited for high-frequency applications. These boards are commonly used in wireless infrastructure, satellite communications, and radar systems.

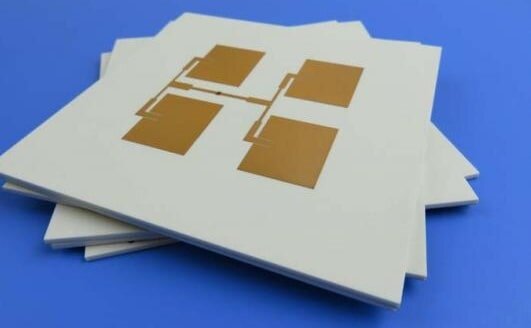

TC350 Material

Flexible LCP Film

Advantages of Rogers PCB Board Materials

Excellent Electrical Performance

The dielectric constant and dissipation factor remain stable at high frequencies and varying temperatures, ensuring efficient and reliable signal transmission, making them particularly suitable for high-speed and RF circuits.

Strong Thermal Management

Excellent thermal conductivity and low coefficient of thermal expansion help dissipate heat from high-power devices, reducing board deformation and solder joint damage.

Easy Processing

Types such as RO4350B can be processed using the same process as FR-4, reducing manufacturing complexity and costs while improving production efficiency.

Strong Environmental Resistance

rogers pcb board material

Excellent moisture and corrosion resistance make them suitable for harsh operating environments such as aerospace, marine, and military applications. Typical Applications of Rogers PCB Material

5G communications equipment: antennas, base station filters, RF front-end modules, etc.

Automotive radar systems: millimeter-wave radar, autonomous driving perception modules.

Aerospace: satellite communication modules, avionics systems.

Medical equipment: RF imaging systems, microwave therapy devices.

Military radar and communications: high-frequency jamming systems, signal processing modules.

High-end routers and switches: data centers, edge computing servers, and other high-speed interconnect devices.

Rogers pcb board material, with its superior technical specifications and diverse product range, meets the electronics industry's demand for high-performance materials. Whether in RF and microwave circuit boards, flexible circuit boards, or high-power electronic devices, Rogers PCB material demonstrates its unique advantages. With the growing demand for high-speed signal transmission and high-frequency microwave technology, rogers pcb board material will continue to play a key role in the PCB industry.