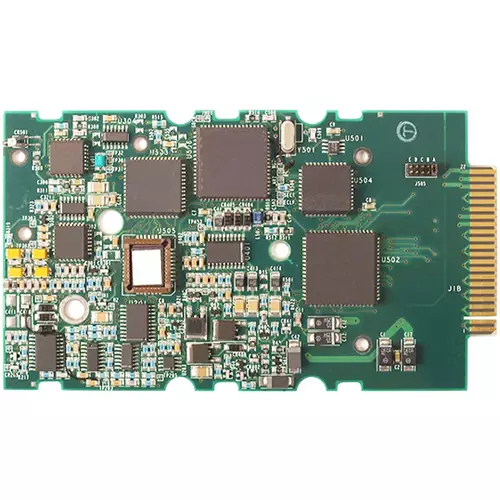

Product Name: Semiconductor Equipment PCBA

Surface technology: Immersion gold+gold finger

Green soldermask/white silkscreen

PCB testing: Yes

PCBA testing: Yes

Provide PCB manufacturing: Yes

iPCB provides complete electronic components.

PCBA testing: Yes

(Customer provides testing steps with video)

RoHS compliant lead-free assembly

Application: Semiconductor Equipment

Semiconductor equipment includes semiconductor equipment, packaging equipment, and testing equipment. Semiconductor equipment is one of the most important devices in the semiconductor production process, mainly divided into two categories: front-end process equipment and back-end process equipment. The testing equipment in semiconductor devices is an important link in ensuring the quality and reliability of semiconductor products. Testing equipment is the process of inspecting and evaluating semiconductor products to ensure that their quality and performance meet the requirements.

With the continuous development and progress of semiconductor technology, semiconductor manufacturing equipment is also constantly evolving and improving.

Higher production efficiency: With the continuous expansion of the semiconductor market and intensified competition, semiconductor equipment requires higher production efficiency to meet market demand. In order to improve production efficiency, semiconductor equipment needs to achieve faster speed, higher accuracy, and more reliable stability. For example, robotic arm equipment needs to achieve faster and more accurate handling and positioning, while control systems need to achieve more efficient and stable control and scheduling.

More refined manufacturing processes: With the increasing complexity of semiconductor chips and the continuous refinement of process requirements, semiconductor equipment needs to have more refined manufacturing processes. For example, lithography equipment needs to achieve finer lithography lines and higher resolution, while thin film deposition equipment needs to achieve more uniform and stable thin film deposition. In addition, etching equipment, measuring equipment, etc. also need to continuously improve process technology to adapt to more refined process requirements.

More intelligent control system: With the continuous development of automation technology and artificial intelligence technology, semiconductor equipment needs to achieve more intelligent control systems. By introducing technologies such as artificial intelligence and machine learning, autonomous control and optimized scheduling of equipment can be achieved, improving production efficiency and product quality. For example, the control system can learn and analyze production data through machine learning algorithms to achieve precise control and optimization of the production process.

More environmentally friendly production methods: With the continuous improvement of environmental awareness and the increasingly strict policies and regulations, semiconductor equipment needs to achieve more environmentally friendly production methods. During the manufacturing and use of equipment, it is necessary to minimize the impact on the environment as much as possible, such as adopting energy-saving design and reducing waste emissions. In addition, the equipment also needs to continuously improve its process technology to reduce environmental pollution.

More flexible production lines: With changes in market demand and technological development, semiconductor equipment needs to achieve more flexible production lines. The production line needs to have higher adaptability, scalability, and maintainability to adapt to chip production of different types and process requirements. For example, production lines can achieve flexible combination and expansion of different equipment through modular design, and predictive maintenance and rapid repair of equipment can be achieved through intelligent maintenance systems.

Lower manufacturing costs: In order to improve market competitiveness, semiconductor equipment needs to achieve lower manufacturing costs. Cost control and optimization are necessary for material selection, design optimization, and production processes of equipment. For example, devices can use new materials, optimize structural design, simplify production processes, and other methods to reduce manufacturing costs. In addition, equipment also needs to reduce operating costs by improving production efficiency and reducing failure rates.

The development trend of semiconductor equipment is multifaceted, including improving production efficiency, achieving finer manufacturing processes, implementing smarter control systems, implementing more environmentally friendly production methods, implementing more flexible production lines, and reducing manufacturing costs. These development trends will help improve the performance and market competitiveness of semiconductor equipment, and promote the sustainable development of the semiconductor industry.

Product Name: Semiconductor Equipment PCBA

Surface technology: Immersion gold+gold finger

Green soldermask/white silkscreen

PCB testing: Yes

PCBA testing: Yes

Provide PCB manufacturing: Yes

iPCB provides complete electronic components.

PCBA testing: Yes

(Customer provides testing steps with video)

RoHS compliant lead-free assembly

Application: Semiconductor Equipment

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.