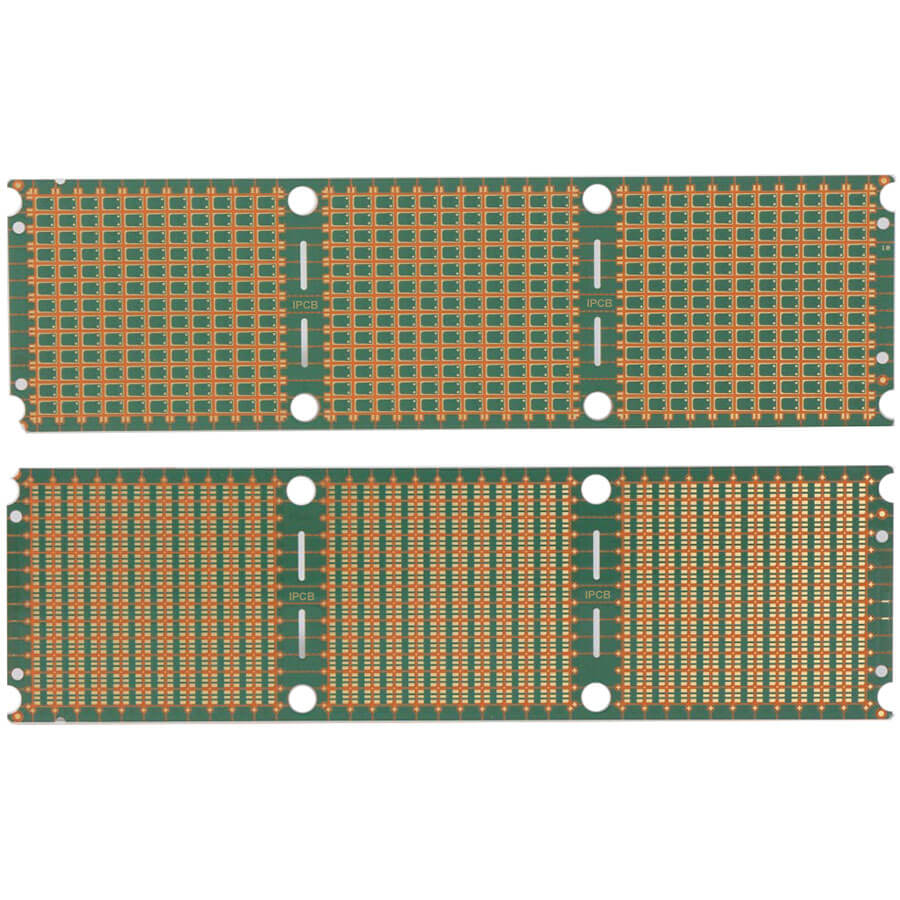

Product name: Sensing IC carrier board

Substrate: Shengyi SI10U

Layer: 4L

Finished board thickness: 0.25mm

Stacking: 1-2-1 HDI

Minimum line width/space: 35 / 35 μ m

Surface treatment: soft gold

Solder mask ink: TAIYO PSR4000 AUS308

Aperture: laser hole = 0.075mm, mechanical hole = 0.1mm

Features of Shengyi si10u: low CTE, high modulus, can effectively reduce the warpage of the packaging substrate, excellent heat and moisture resistance, good PCB processability, halogen-free material, tg280.

Sensor IC carrier board

The automobile oxygen sensor is a very important source of response information in the automobile engine control system. The oxygen content in the exhaust gas will determine the amount of fuel injected by the electronically controlled injector and the air intake amount of the intake manifold. This data will determine the car's fuel consumption. And whether the vehicle's emission standards meet the standards. The characteristics of the oxygen sensor can be fully demonstrated and the voltage can be output only when the temperature is above 300°C. This will be very important for the selection of carrier board.

Once the oxygen sensor works abnormally, the engine control unit will receive an incorrect mixture concentration echo signal, which will affect the precise control of the fuel injection amount. Under normal circumstances, when the oxygen sensor ages and its working efficiency begins to decrease:

A signal that the mixture is too lean is sent out, causing the engine control unit to increase the amount of fuel injection, thereby increasing fuel consumption, usually by 15%.

The engine power output is reduced, which affects the acceleration performance, the control efficiency becomes worse, and the driving pleasure is lost.

The concentration of the mixed gas is too high, incomplete combustion products are added, and the emissions exceed the standard.

If the mixture burns too richly for a long time, the engine operating temperature will be too high, and the expensive catalytic conversion device will be seriously damaged.

Currently, there are three main types of carrier boards used in automotive sensors: epoxy resin carrier boards, metal carrier boards, and ceramic carrier boards. For the oxygen sensor carrier board, the epoxy resin carrier board can be eliminated first, because epoxy resin cannot withstand high temperatures above 300°C, so only metal carrier boards and ceramic carrier boards are left. Currently, metal carrier boards are mainly copper carrier boards and aluminum carrier boards. However, both copper carrier boards and aluminum carrier boards are conductors. If used as carrier boards, they require an insulating layer before they can be used. However, the insulating layer It is also not able to withstand high temperatures above 300°C. So only ceramic carrier boards can still be used.

There are currently two main applications of ceramic carrier boards, one is alumina ceramic carrier board, and the other is aluminum nitride ceramic carrier boards. The biggest difference between the two carrier boards is the thermal conductivity. The thermal conductivity of alumina ceramic carrier boards Generally, it is 35W/(m·K), while aluminum nitride can reach a terrifying 230W/(m·K). As for withstanding temperature, both carrier boards can operate at high temperatures above 300°C.

It can be seen that the most suitable aluminum oxide sensor is the aluminum nitride ceramic carrier board. Only the aluminum nitride ceramic carrier board can dissipate heat in time and perform circuit heating faster, which can perfectly ensure that the exhaust gas contains oxygen. Amount of data transfer.

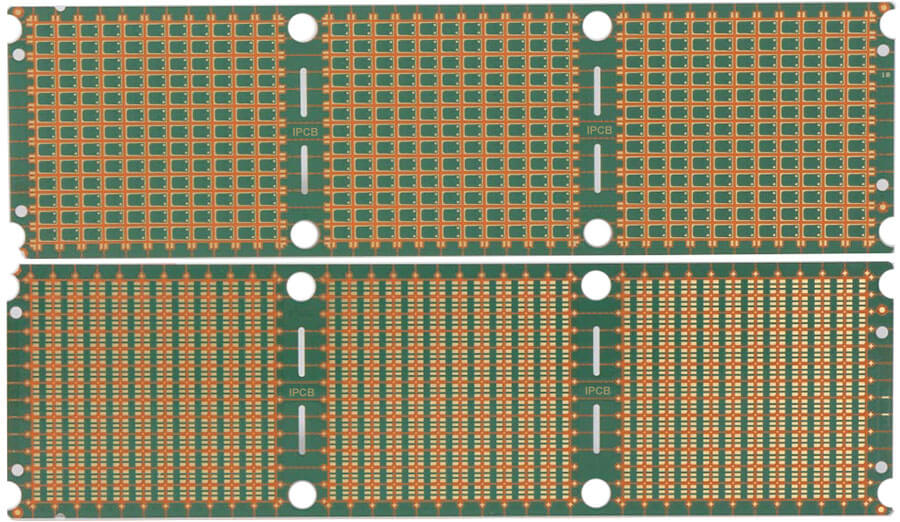

Product name: Sensing IC carrier board

Substrate: Shengyi SI10U

Layer: 4L

Finished board thickness: 0.25mm

Stacking: 1-2-1 HDI

Minimum line width/space: 35 / 35 μ m

Surface treatment: soft gold

Solder mask ink: TAIYO PSR4000 AUS308

Aperture: laser hole = 0.075mm, mechanical hole = 0.1mm

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.