High-TG PCB (high glass transition temperature printed circuit board) is a key performance indicator for PCB materials. It refers to the temperature at which the material transitions from a rigid glassy state to a flexible rubbery state. For common PCB substrate materials, such as FR-4, the Tg value is approximately 130°C to 150°C. When the temperature rises above a certain level, it softens, deforms, or even melts, and its mechanical and electrical properties deteriorate dramatically. High-TG PCBs have a glass transition temperature (Tg) significantly higher than that of conventional FR-4 materials (typically ≥170°C). As electronic devices evolve toward high-performance, high-density, and high-temperature environments, high-TG PCBs have become a key material due to their excellent heat resistance, mechanical stability, and reliability.

Core Features of High TG PCB

1. Excellent Thermal Stability: High-TG PCBs have a lower CTE in the Z-axis, minimizing differential expansion with copper layers and components at high temperatures, reducing the risk of solder joint cracking. This effectively minimizes performance changes caused by thermal expansion. In devices that operate in high-temperature environments for extended periods, conventional PCBs can cause problems such as broken circuits and loosened solder joints due to thermal expansion and contraction. High-TG PCBs, with their excellent thermal stability, ensure stable operation.

2. Excellent Electrical Performance: In high-frequency applications, high-TG materials typically exhibit more stable dielectric constants (Dk) and dissipation factors (Df), making them suitable for high-speed signal transmission.

3. High Mechanical Strength: They offer enhanced flex and impact resistance in high-temperature environments, making them suitable for harsh operating conditions (such as automotive engine compartments).

4. Excellent Moisture Resistance: In humid environments, conventional PCB materials may absorb moisture, resulting in degraded electrical performance and even causing short circuits and other faults. High-TG PCBs, however, have a lower moisture absorption rate and strong moisture resistance, ensuring stable operation in humid environments.

Figure 1: High TG PCB maintains stable working state in humid environment

Common materials for high TG PCB

1.Enhanced epoxy resin: such as Isola 370HR (Tg 180 ° C), Tuc 862 (Tg 170 ° C).

2.BT resin: used for IC carrier boards, with a Tg of approximately 180-220 ° C.

3.Polyimide (PI): Tg can reach above 250 ° C, used in high extreme environments such as aerospace.

4.Ceramic filling material: such as Rogers RO4835 (high-frequency high TG hybrid material).

Common high TG PCB types and characteristics

Commonly used high TG PCBs are mainly high TG FR-4, divided into different performance levels

1. High TG FR-4 (Tg 170 ℃ -180 ℃)

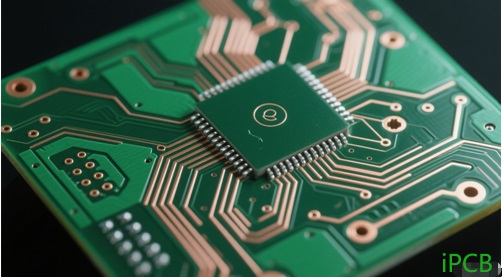

The most widely used is the upgraded version of the regular FR-4. The substrate is mostly dark green, the copper foil circuit is smooth, the thermal decomposition temperature is above 320 ℃, and it is not easy to layer and bubble during welding. Used for automotive electronics, industrial power supplies, etc., with high cost-effectiveness.

Figure 2: High TG FR-4 (Tg 170 ℃ -180 ℃) PCB board

2. Ultra high TG FR-4 (Tg 180 ℃ -200 ℃)

When the long-term operating temperature of the equipment exceeds 120 ℃, it should be selected. The substrate has high hardness and is partially coated with blue or black solder mask. The thickness tolerance of the board is strict, making it suitable for high-density wiring. Used for 5G base station power amplifiers, high-end server motherboards, etc.

Figure 3: Ultra high TG FR-4 (Tg 180 ℃ -200 ℃) PCB board with blue solder mask layer

3. Special high TG materials (Tg above 200 ℃)

Based on polyimide, BT resin, etc., with a Tg of over 250 ℃, low radiation resistance and moisture absorption. Polyimide substrate is brownish yellow and lightweight; The BT resin substrate is light yellow and has a smooth surface. Used for aerospace, medical high-frequency instruments, etc., with a relatively high price.

Figure 4: Brown yellow polyimide substrate special high TG material PCB board

Common features: No deformation after high temperature treatment, continuous in a 200 ℃ oven for 2 hours, with warpage controlled within 0.2%

Differences in raw materials between high TG board and ordinary board

The core difference between high TG board and ordinary board lies in the raw material formula and performance, which directly affects Tg and overall performance:

1. Different resin systems: ordinary boards are made of ordinary epoxy resin with a Tg of 130 ℃ -150 ℃; High TG board is made of modified epoxy resin or special high-performance resin, with a Tg of 170 ℃ or above.

2. Fillers and reinforcement materials: Adjust the parameters of glass fiber cloth or add special fillers to high TG board to enhance high temperature stability; Ordinary boards focus on cost control.

3. Process adaptability: High TG materials require higher temperature and pressure curing to form high-temperature resistant structures.

Key application areas of high TG PCB

1. High frequency communication equipment:

5G base stations handle a lot of data and generate a lot of heat. High TG PCBs meet the electrical performance requirements at high temperatures and are used in base stations, routers, etc. to ensure signal transmission.

2. Medical devices

Medical equipment has extremely high requirements for safety and reliability. Some medical equipment, such as high-temperature disinfected medical devices, need to withstand high temperature environments during the disinfection process. High TG PCBs can maintain stable working conditions under such harsh conditions, providing reliable guarantees for the normal operation of medical equipment and ensuring patient safety.

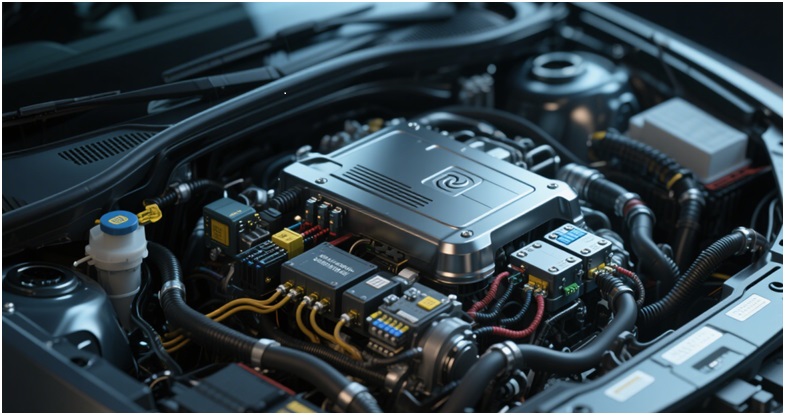

3. Automotive Electronics

The engine compartment temperature of a car is high, and electronic devices need to be resistant to high and low temperatures, as well as humidity. High TG PCB is used for engine management systems, sensors, etc., such as new energy vehicle battery management systems, to ensure the safe and efficient operation of batteries

Figure 5: Electronic devices inside the engine compartment of a car, using high TG PCB to cope with high temperatures

4. Aerospace

Aerospace electronic equipment operates in extreme environments, and high TG PCBs are used in aircraft, satellites, and other applications such as satellite communication modules to ensure smooth mission execution.

5. Industrial control

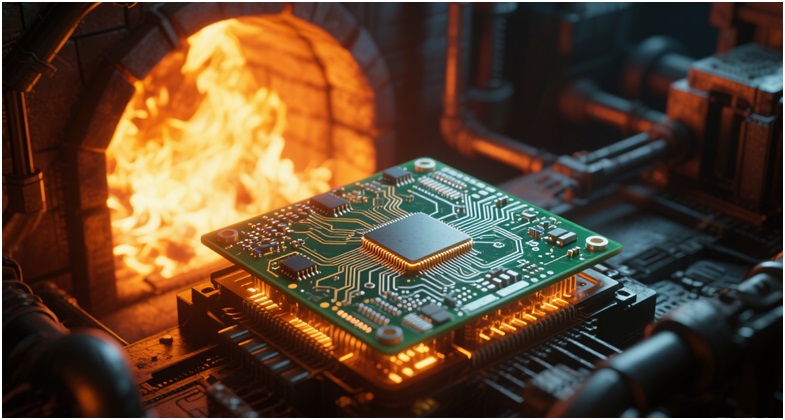

The industrial environment is harsh, and high TG PCBs ensure stable operation of controllers and monitoring equipment in industries such as steel and chemical equipment. For example, in the temperature control system of industrial kilns, high TG PCBs can accurately control and monitor the temperature inside the kiln, ensuring the production quality of products.

Figure 6: High TG PCB in Industrial Kiln Temperature Control System

Challenges in High TG PCB Manufacturing Process

1.Optimization of lamination process: High TG materials require higher lamination temperatures (possibly up to 200 ° C) and pressures, and parameters need to be adjusted to avoid uneven resin curing.

2.Drilling and processing: The material has high hardness and requires the use of diamond coated drill bits to reduce the roughness of the hole wall.

3.Surface treatment: High temperature soldering (such as lead-free process peak temperature of 260 ° C) requires surface coatings (such as ENIG, OSP) to be compatible with high TG substrates.

High TG PCB has become the cornerstone of high-temperature, high-power, and high-frequency applications by improving heat resistance and reliability. When selecting, it is necessary to comprehensively evaluate Tg, CTE, cost, and process adaptability. In the future, with the advancement of materials science, the demand for high TG PCBs will continue to grow, and they will demonstrate their excellent performance in more fields, promoting the development of electronic devices towards higher performance and reliability.