The process of transferring RF PCB energy from a coaxial connector to a printed circuit board (PCB) is often called signal injection, and its characteristics are difficult to describe. The efficiency of energy transfer will vary greatly depending on the circuit structure. Factors such as PCB material and its thickness and operating frequency range, as well as connector design and its interaction with circuit materials all affect performance. Performance can be improved by understanding different signal injection settings and reviewing some optimization cases of RF microwave signal injection methods.

Achieving effective signal injection is design dependent, and generally wideband optimization is more challenging than narrowband. Generally, high-frequency injection becomes more difficult as the frequency increases. At the same time, there may also be more problems as the thickness of the circuit material increases and the complexity of the circuit structure increases.

RF PCB signal injection design and optimization

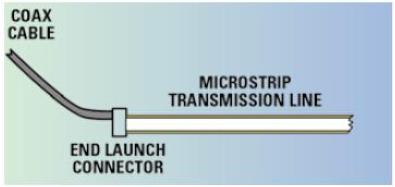

Signal injection from coaxial cables and connectors to microstrip PCBs. The electromagnetic (EM) field distribution across coaxial cables and connectors is cylindrical, while the EM field distribution within a PCB is planar or rectangular. From one propagation medium into another, the field distribution changes to adapt to the new environment, creating anomalies. Changes depend on the type of media; for example, whether signal injection is from coaxial cables and connectors to microstrip, grounded coplanar waveguide (GCPW), or stripline. The type of coaxial cable connector also plays an important role.

Signal injection from coaxial cables and connectors to microstrip

Optimization involves several variables. Understanding EM field distribution within a coaxial cable/connector is useful, but ground loops must also be considered part of the propagation medium. It is often helpful to achieve a smooth impedance transition from one propagation medium to another. Understanding capacitive and inductive reactance at impedance discontinuities allows us to understand circuit behavior. If three-dimensional (3D) EM simulations can be performed, the current density distribution can be observed. In addition, it is best to take into account practical considerations regarding radiation losses.

Although a ground loop between the signal launch connector and the PCB may not appear to be a problem, with a very continuous ground loop from the connector to the PCB, this is not always the case. There is usually a small surface resistance between the metal of the connector and the PCB. There are also small differences in the conductivity of the soldering shops and metals that connect different parts. At lower RF and microwave frequencies, these small differences generally have less impact, but at higher frequencies they can have a significant impact on performance. The actual length of the ground return path affects the transmission quality that can be achieved with a given connector and PCB combination.

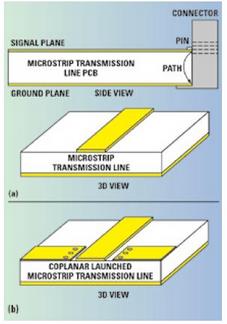

As electromagnetic wave energy travels from the connector pins to the signal wires of a microstrip PCB, the ground return path back to the connector housing may be too long for thick microstrip transmission lines. Using PCB materials with higher dielectric constants can worsen the problem by adding electrical length to the ground loop. Path lengthening causes frequency-dependent problems, resulting in local phase velocity and capacitance differences. Both are related to and affect the impedance within the transformation region, resulting in return loss differences. Ideally, the length of the ground loop should be minimized so that there are no impedance anomalies in the signal injection area. Note that the connector shown in Figure 2a has its ground point only at the bottom of the circuit, which is the worst case scenario. Many RF connectors have their ground pins on the same layer as the signals. In this case, the ground pad will also be designed there on the PCB.

The figure below shows a grounded coplanar waveguide to microstrip signal injection circuit. Here, the main body of the circuit is microstrip, but the signal injection area is a grounded coplanar waveguide (GCPW). Coplanar emission microstrip is useful because it minimizes ground loops and has other useful properties. If you use a connector with ground pins on both sides of the signal conductor, the ground pin spacing has a significant impact on performance. This distance has been shown to affect frequency response.

Thick microstrip transmission line circuit and long ground return path to connector (a)

Grounded coplanar waveguide to microstrip signal injection circuit (b)

When conducting experiments using coplanar waveguide to microstrip based on Rogers' 10mil thick RO4350B laminate, a connector with a different ground spacing at the coplanar waveguide port but similar other parts was used. Connector A has a ground separation of approximately 0.030", while Connector B has a ground separation of 0.064". In both cases, the connector launches onto the same circuit.

Testing coplanar waveguide-to-microstrip circuits using port-like coaxial connectors with different ground spacing

The x-axis represents frequency, with 5 GHz per division. When the microwave frequency is lower (< 5 GHz), the performance is equivalent, but when the frequency is higher than 15 GHz, the performance of circuits with larger ground separation becomes worse. The connectors are similar, although the pin diameters of the 2 models are slightly different, with Connector B having larger pin diameters and designed for use with thicker PCB materials. This may also lead to performance differences.

A simple and effective signal injection optimization method is to minimize the impedance mismatch in the signal emission area. The rise in the impedance curve is basically due to the addition of inductors, while the drop in the impedance curve is due to the addition of capacitors. For thick microstrip transmission lines (assuming the PCB material has a low dielectric constant, about 3.6), the wires are wider - much wider than the inner conductor of the connector. Due to the large size difference between circuit wires and connector wires, there will be strong capacitive jumps during transition. Capacitive jumps can usually be reduced by tapering the circuit wire to reduce the size gap where it connects to the coaxial connector pins. Narrowing a PCB trace increases its inductance, or decreases its capacitance, thereby offsetting the capacitive jump in the impedance curve.

The effect on different frequencies must be considered. Longer gradient lines will produce stronger sensitivity to low frequencies. For example, if the return loss is poor at low frequencies and there is a capacitive impedance spike, a longer gradient line may be appropriate. On the contrary, shorter gradient lines have a greater effect on high frequencies.

For coplanar structures, additional capacitance is added when adjacent ground planes are close together. Usually, the inductance and capacitance of the signal injection area in the corresponding frequency band is adjusted by adjusting the distance between the gradient signal line and the adjacent ground. In some cases, the adjacent ground pads of the coplanar waveguide are wider on one section of the gradient to accommodate lower frequency bands. The spacing then narrows in the wider portion of the gradient line, which is not long enough to affect the higher frequency PCB. Generally speaking, narrowing the wire gradient creates new sensuality. The length of the gradient line affects the frequency response. Changing the adjacent ground pads of a coplanar waveguide can change the capacitance. The reason why the pad spacing can change the frequency response is that the change in capacitance plays a major role.