Copper is an excellent conductor for RF/microwave printed circuit boards. It is the basis for designing low loss transmission lines such as microstrip lines and strip lines. However, the surface roughness of copper foil may vary on different circuit materials, even in different areas of the same material, which can affect high-frequency performance. In an ideal situation, in order to provide consistent signal transmission characteristics on and between circuit boards, the copper foil on the circuit board should be smooth and well consistent. However, in reality, the copper foil surface of any copper-clad laminated circuit board has a certain roughness, which may affect the final performance of the circuit board.

Some electromagnetic simulation software allows users to define key characteristics of added circuit board materials, such as dielectric constant (Dk) and copper foil surface roughness. In the process of circuit design and performance simulation, it is possible to make the simulation results very consistent with the actual circuit measurement results, even if there is a certain degree of variation in the surface roughness of the copper foil throughout the circuit board.

What is dielectric constant?

When modeling and simulating circuits in commercial electromagnetic simulation software, it is important to fully consider the influence of copper foil surface roughness on circuit board materials, understand how copper foil surface roughness affects the performance of high-frequency circuits, and the relationship between Dk and copper foil surface roughness of materials. In fact, the Dk value of circuits made of circuit board materials is affected by the surface roughness of copper foil. In electromagnetic simulation software, the Dk value of such circuits is usually referred to as the Design Dk value.

For example, due to changes in the Copper foil roughness, the phase response of circuits processed on this material may undergo unpredictable changes. Under certain high-frequency application conditions (due to the smaller wavelength of the signal), this change will be more significant, such as the electronic safety systems currently used in advanced driver assistance systems (ADAS) in automobiles, and the millimeter wave frequency band planned for high-speed short-range data links in fifth generation (5G) mobile wireless communication networks.

The design Dk value is frequency dependent, usually taking the value at 10GHz as the design Dk value, and the Dk value may vary at different frequencies. The design Dk is obtained from testing microstrip transmission line circuits and is the Dk value in the z-axis (thickness) direction of the material.

Some electromagnetic simulation software only uses the design Dk values in the z-axis direction for simulation, while others may require both the z-axis and x-y plane Dk values of the circuit board material. When considering the anisotropic parameters of a circuit, it is usually necessary to input the Dk value of the material in the x-y plane in the software.

Which dielectric constant should be used?

The design Dk value of circuit board materials is extremely important for the accuracy of circuit electromagnetic simulation. Understanding the testing method for the design Dk value of a specific material by circuit board material manufacturers is very helpful. The design Dk of the material is obtained through the use of microstrip differential phase length testing method.

Although the Dk value of circuit board materials can be measured under strict environmental control conditions, there are still many Dk testing methods based on existing circuits. For example, microstrip ring resonator method and microstrip differential phase length method. Under precise testing conditions (frequency), the performance measurement of the circuit reveals the characteristics of the circuit board material, which helps determine its Dk value. However, any changes in the circuit, such as conductor etching and copper plating thickness, can lead to inaccurate measurement of material Dk values. When using multi-layer circuits (such as strip line based circuits) to determine the Dk of materials, other variables may also lead to inaccurate measurement of the Dk value of circuit board materials. For example, the thickness variation of the inner layer of the multi-layer board, or the Dk of the adhesive material used for connection may be different from that of the core board material. Therefore, in order to obtain accurate simulation results in simulation software, these factors must be taken into account when determining the Dk of the circuit board material or the final design Dk.

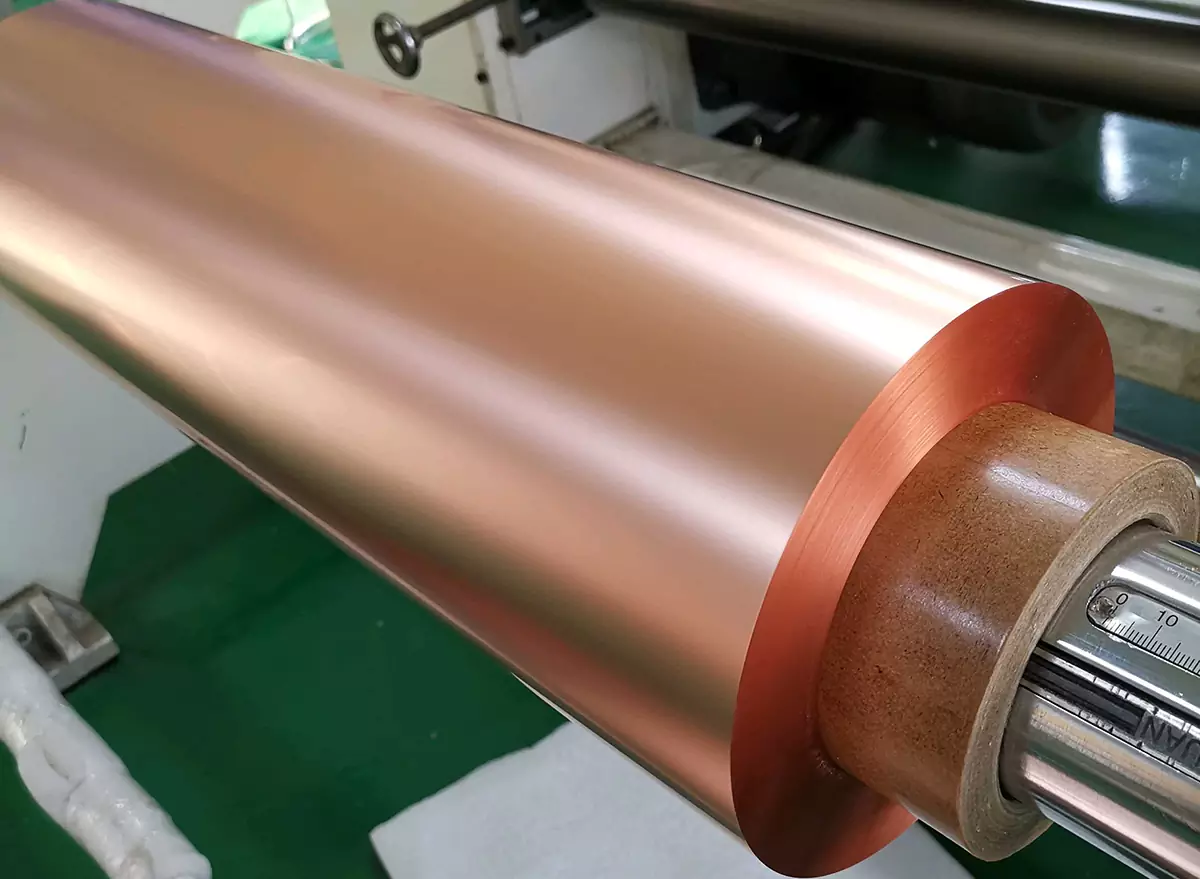

PCB copper foil

Rogers PCB provide design Dk values, and the testing method is based on microstrip transmission line circuits to determine the material's Dk value. These design Dk values are clearly indicated in the circuit board material data sheet, and this Dk value does not include the influence of Copper foil roughness. However, the MWI-2018 software tool provides information on the effects of copper foil roughness and more detailed material design Dk, which is very useful for circuit modeling in commercial electromagnetic simulation software. MWI-2018 can be downloaded for free from Rogers Technical Support Center.

Rogers' MWI-2018 software can display the design Dk value of each circuit board material through various options. One option is Bulk Dk, which only considers the material itself and does not take into account the influence of copper foil surface roughness. This design Dk value can be used in simulation software to calculate the phase response effect caused by copper foil roughness on the circuit, without the need for a "preloaded" design Dk value. When some simulation software does not embed such simulators, it is necessary to choose another design Dk value that includes the influence of copper foil surface roughness.

At present, many commercial electromagnetic simulation software can model the circuit of the influence of Copper foil roughness on phase response. For example, HFSS electromagnetic simulation software from ANSYS, CST Studio suite from Computer Simulation Technology, and Sonnet electromagnetic simulation software from Sonnet Software. ANSYS HFSS software can predict the phase effect of copper foil surface roughness in circuits. These electromagnetic simulation software can already calculate the influence of copper foil surface roughness on circuit phase performance, and therefore do not require additional data or design Dk values that do not include the influence of copper foil roughness, Bulk Dk.

For simulation software that cannot predict the effect of Copper foil roughness, design Dk containing the effect of copper foil roughness should be used instead of "Bulk Dk". These values can be found in the MWI-2018 tool software, which includes design Dk for all Rogers materials. Choosing different Dk values during simulation can affect the accuracy of the simulation results. For simulation software that can calculate the effect of copper foil surface roughness on circuit phase response, the Bulk Dk value should be selected because the simulation software has already taken into account these phase effects caused by copper foil. If the design Dk value with the influence of copper foil roughness is selected again, the circuit simulation will consider the impact of copper foil roughness twice, resulting in inaccurate simulation.

Do you have any questions regarding the design or manufacturing of high-frequency circuit board? iPCB can provide you with relevant assistance. Please contact iPCB's engineers for help now.