With the increasing demand for thinner, smarter, and higher-density electronic products, Flexible Printed Circuit Boards (FPCBs) have become a critical component in modern electronics design. Among various types of FPCBs, the Single-Sided Flexible PCB stands out for its simplicity, light weight, and flexibility. It is widely applied in consumer electronics, wearable devices, LED lighting, automotive electronics, and industrial control systems. This article provides an in-depth analysis of single-sided flexible PCBs, including technical structure, key features, design considerations, application scenarios, and future development trends, providing engineers with practical technical insights.

1. Overview and Structure of Single-Sided Flexible PCB

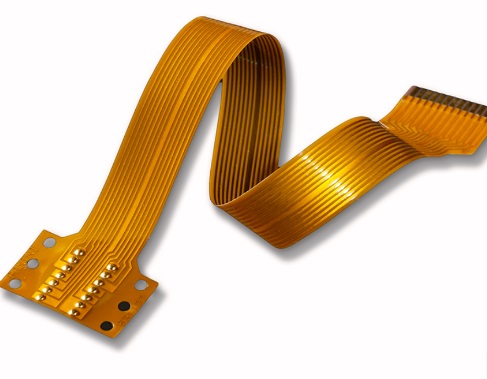

A single-sided flexible PCB is a flexible board with copper traces only on one side, enabling reliable signal and power transmission while offering flexibility and lightweight characteristics. Its core structure consists of:

1.1Flexible Substrate

Common materials: Polyimide (PI) and Polyester (PET)

Thickness range: 12–50 μm, commonly 25 μm

Properties: High temperature resistance (PI up to 260°C), excellent mechanical flexibility, suitable for repeated bending

1.2 Copper Foil

Single-sided traces, copper thickness typically 9–35 μm (1/3–1 oz)

Determines current carrying capacity, e.g., 1 oz copper with 0.2 mm trace can carry ~1A

Copper may be electrodeposited or rolled, ensuring stable electrical performance

1.3 Coverlay / Solder Mask

Protects copper traces from short circuits, oxidation, and mechanical damage

Commonly flexible PI coverlay or liquid solder mask, with temperature resistance of 230–260°C

In bending regions, coverlay is often thinned to improve flex lifespan

1.4 Vias / Through-Holes (Optional)

Rarely used in single-sided flexible PCBs

Only applied when components need mechanical support or strengthening

1.5 Connector Interface

Often connected to Wire-to-Board connectors or FPC sockets

Can use crimping, soldering, or insulation displacement contact (IDC) methods for reliable external connection

2. Key Features and Advantages

2.1 Single-Sided Traces and Simple Structure

Traces are only on one side, simplifying design and manufacturing

Electrical performance is stable and suitable for low to medium complexity circuits

Lower difficulty and higher yield compared to double-sided or multilayer flexible PCBs

2.2 Flexibility and Thin Profile

Total thickness: 0.05–0.15 mm, weight reduced by 50–70% compared to rigid PCB

Minimum bending radius typically ≥5× board thickness

Bending lifespan: 5,000–10,000 cycles depending on copper thickness, trace width, and bending radius

Ideal for foldable electronics and wearable devices due to space-saving properties

2.3 High Temperature Resistance and Reliability

Polyimide substrate tolerates up to 260°C, compatible with reflow and wave soldering

Coverlay protects traces from oxidation

Flex substrate absorbs mechanical stress under vibration and shock

2.4 Cost-Effectiveness and Customizability

Single-sided design uses less material, resulting in lower production costs

Can be cut into various shapes (L, U, serpentine) for compact or irregular layouts

Unit cost can be 20–40% lower than double-sided or multilayer FPCBs in mass production

2.5 Assembly and Maintenance Convenience

Can be folded or rolled for 3D routing

Reduces the number of connectors, improving system reliability

Easier maintenance or replacement, especially in wearables and complex instruments

3. Design Considerations and Engineering Practices

Despite its simple structure, single-sided flexible PCB design requires attention to the following technical details:

3.1 Trace Design

Minimum trace width: 0.1–0.2 mm

Minimum trace spacing: 0.1–0.2 mm

Current capacity depends on copper thickness and trace width

Example: 1 oz copper, 0.2 mm trace can carry 0.5–1A

Bend areas should avoid overlapping traces; minimum bending radius ≥5× board thickness

Minimize vias in bend areas to reduce stress concentration

3.2 Coverlay and Solder Mask

Thin solder mask in bending areas to reduce mechanical stress

Flexible PI coverlay recommended for longer bending lifespan

Solder mask can be thermally or UV-cured to withstand reflow temperatures

3.3 Component Placement and Mechanical Support

Surface-mount components should be placed in non-bending regions

Pins or connectors require metal reinforcement to prevent solder joint damage

SMT connectors require consideration of pad area and supporting pillars

3.4 Manufacturing and Testing

Production process: substrate lamination → photolithography → etching → solder mask → coverlay → shaping

Reflow soldering temperature: ≤260°C

Bending lifespan test: 5,000–10,000 cycles depending on copper thickness, trace width, and bending radius

Electrical testing: contact resistance ≤20 mΩ, insulation resistance ≥100 MΩ

4. Typical Applications and Data Examples

4.1 Consumer Electronics

Products: smartphones, tablets, laptop foldable cables

Parameters: 12–18 μm copper, 0.08–0.12 mm board thickness, ~8,000 bending cycles

Advantages: lightweight, foldable, suitable for automated assembly

4.2 Wearable Devices

Products: smart bands, smartwatches, health monitoring devices

Features: high-density routing, miniaturization, lightweight

Design considerations: bending radius ≤3 mm, 12 μm copper to ensure durability during daily movement

4.3 LED Lighting

Products: flexible LED strips, advertising screens, automotive LED lighting

Parameters: current 0.5–2A, board thickness 0.1 mm

Advantages: flexible, vibration-resistant, good thermal management

4.4 Automotive Electronics

Products: instrument panels, control modules, sensor wiring

Parameters: operating temperature -40°C to +125°C, vibration resistance 10–20G

Advantages: high reliability, heat tolerance, lightweight

4.5 Industrial and Medical Devices

Products: miniature sensors, control modules

Features: micro-routing, high reliability, high precision

Advantages: reduced space occupancy, extended service life

5. Future Trends

5.1 Miniaturization and High-Density Design

Trace spacing decreasing to 0.05 mm

Multi-folded and high-pin-count designs for complex routing

5.2 High-Speed Signal Transmission

Support USB 3.0, LVDS, HDMI, and other high-speed interfaces

Differential routing and shielding layers becoming standard

5.3 Advanced High-Reliability Materials

Polyimide (PI), Liquid Crystal Polymer (LCP) with chemical resistance

Gold-plated contacts and flexible coverlay to extend bending life

5.4 Smart Manufacturing and Testing

Automated photolithography, laser cutting, and online bending lifespan testing

CAD/CAE simulation for bending stress optimization

6. Conclusion

Single-sided flexible PCBs provide single-sided traces, thin and flexible form factor, high-temperature resistance, reliability, and easy assembly, making them indispensable in modern electronic designs. Engineers should focus on:

Material selection and copper thickness matching current and temperature requirements

Trace width, spacing, and bending radius optimization to ensure durability

Coverlay and solder mask design for mechanical stress protection

Component placement and mechanical reinforcement for long-term reliability

High-density, high-speed, and miniaturization trends for future complex electronics

By combining engineering data with practical application experience, single-sided flexible PCBs can not only meet conventional electronic performance requirements but also deliver long lifespan and high reliability in wearable devices, LED lighting, automotive electronics, and medical equipment. Mastering these technical insights enables engineers to make informed design and selection decisions, enhancing product reliability and competitiveness.