PCB SMT Prototype Assembly, also commonly referred to as SMT sample assembly or SMT prototyping, involves mounting and soldering components onto a small number of PCBs using SMT (Surface Mount Technology) before mass production. This process is used to verify circuit design, structural layout, and overall functionality.

Compared to large-scale SMT production, prototype assembly is characterized by small quantities, fast turnaround times, and high flexibility, emphasizing engineering support capabilities, process adaptability, and an understanding of design details.

Electronic assembly is the process of integrating various electronic components onto a printed circuit board (PCB), involving multiple steps to ensure complete circuit functionality. SMT technology, as a crucial part of electronic assembly, achieves high-density component mounting through automated equipment, improving overall manufacturing levels.

SMT Prototype Assembly

Now that we understand what SMT PCBA is, let's detail the SMT prototype assembly process. In the surface mount process, we typically perform the following steps:

1. Material Inspection

The first step in the SMT PCB assembly process is a comprehensive inspection of all incoming electronic components. This includes not only the PCB itself but also all components. Every SMD component must exactly match the BOM (Bill of Materials) provided by the customer, including package type, size, and appearance specifications. The PCB must also be in perfect condition, without warping, cracks, or other damage, to ensure smooth subsequent assembly.

2. Preparation Before SMT Assembly

After confirming that all materials are available, thorough preparation is required for SMT PCB prototype assembly. This includes creating solder paste stencils, baking the PCBs and BGA chips, preparing the pick-and-place files required for mounting, and configuring the appropriate feeders for the SMT assembly process. All these preparations ensure that the placement process is smooth and accurate.

3. Solder Paste Application

Once the preparations are complete, the surface mount assembly of the PCB can begin. The first step is to evenly apply solder paste to the pads of the PCB. This requires a customized stainless steel stencil corresponding to the PCB pads, through which the solder paste is precisely printed onto the circuit board surface. This step is crucial for ensuring solder joint reliability and welding quality.

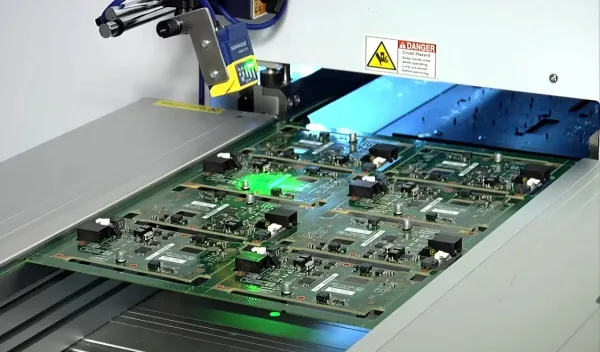

4. Component Placement Using a Pick-and-Place Machine

We use high-precision pick-and-place machines to place SMD components onto PCBs printed with solder paste. High-precision machines are used to ensure accurate placement of components on the PCB pads. SMD PCB components are typically supplied in reels/trays, but it is also common for SMD PCB components to be supplied in loose packaging for prototype surface mount PCB assembly. They are loaded into the pick-and-place machine. The SMT machine places these SMD PCB components in the correct positions, placing them at the pre-programmed correct XY coordinates. After SMT assembly is complete, the SMD PCB components are soldered to the PCB in a reflow oven. After placing the SMD PCB components on the first PCB, but before going through the reflow oven, our online production engineers will perform a first-article inspection to ensure the SMD PCB components are correct. Dedicated first-article testing equipment is required for this SMT PCB manufacturing process.

5. Soldering Components on the PCB

The circuit boards are placed in a long conveyor-belt-style reflow oven. This process heats the circuit board until the solder paste slowly melts. The ideal temperature profile ensures that the solder paste melts and solidifies optimally. This creates a strong, permanent connection for all components. Reflow ovens typically use nitrogen gas to prevent contamination.

6. 100% AOI Inspection

All PCBs undergo visual inspection using Automated Optical Inspection (AOI), a system that works with high-speed cameras. For parts that cannot be seen, X-ray inspection is used, which can verify the quality of hidden solder joints. If problems are found during the inspection, rework or repair is performed, and the cause of the problem is analyzed.

7. 100% Visual Inspection

100% visual inspection refers to a manual inspection of each PCB, board by board and area by area, by experienced inspectors after the SMT prototype assembly is completed. This inspection serves as an important complement to automated inspections (such as AOI, X-ray), mainly to confirm that the soldering appearance and assembly details meet the process requirements.

8. Final Inspection and Anti-Static Packaging

After all tests and inspections are completed and confirmed as qualified, the prototypes will enter the final inspection stage. After final confirmation, the PCBs will be professionally packaged using anti-static materials to effectively prevent electrostatic damage, mechanical collisions, and environmental influences, ensuring the product remains in good condition during transportation and storage.

SMT Prototype Assembly

Common Defects in SMT Prototype Assembly

The goal of SMT assembly is zero defects. As circuit board sizes shrink, problems can arise. To produce high-quality products, these potential defects must be identified and addressed. Below are some common defects we encounter during the SMT assembly process.

1. Insufficient Solder Coverage

This error results in broken or weak connections on the circuit board. This is caused by insufficient solder, leading to a weak connection between the component and the PCB pad. This may be due to printing errors or insufficient solder paste. It could also be due to an unoptimized stencil design. Low reflow soldering temperature can also be a contributing factor.

2. Solder Bridging

Solder bridging refers to solder incorrectly connecting two contacts. This creates an unintended circuit on the board. This can lead to potential short circuits and subsequent malfunctions. Excessive solder paste can also cause bridging. An unoptimized temperature profile in the reflow oven can also lead to bridging.

PCB SMT Prototype Assembly is not just simple "surface mount prototyping," but a comprehensive process that integrates design understanding, process experience, and engineering services. High-quality prototype assembly helps customers identify problems earlier, reduce R&D risks, and lay a solid foundation for subsequent mass production. In the increasingly competitive electronics manufacturing industry, choosing professional and reliable PCB SMT prototype assembly services will be a crucial guarantee for product success.