On the solder mask,openings need to be created to allow the PCB pads to be soldered or connected, and some vias without PCB ink are covered for heat dissipation. These openings on the solder mask are called solder mask openings.Solder mask openings are used to expose the PCB to solder/tin. It needs to be precise, otherwise the copper on the circuit board may be exposed unnecessarily, causing corrosion and damage. In layman's terms,it is to remove the paint layer on the circuit so that the circuit can expose the tin.

Concept of solder mask:

The solder mask is the soldermask, which refers to the part of the printed circuit board that is to be painted with green oil. In fact, this solder mask uses a negative film output, so after the shape of the solder mask is mapped to the board, it is not painted with green oil solder mask, but the copper skin is exposed.

The solder mask is a thin layer of polymer coating, usually applied to the copper surface of the printed circuit board (PCB), designed to prevent oxidation and avoid the formation of solder bridges between closely spaced pads, that is, undesirable electrical connections between two conductors, usually achieved by a small piece of solder. Solder mask is not necessarily used for hand soldering components, but it is critical for boards that are mass produced using reflow or wave soldering techniques. Once applied, holes must be opened in the solder mask by photolithography to allow connections to be made at any location where the components are soldered. Traditionally, solder mask is green, but many other colors are available.

Process requirements for solder mask:

The role of solder mask in controlling soldering defects during the reflow soldering process is important, and PCB designers should try to minimize the spacing or air gaps around pad features. Although many process engineers would rather have solder mask separate all pad features on the board, the pin spacing and pad size of fine-pitch components will require special considerations. Although unpartitioned solder mask openings or windows on four-sided QFPs may be acceptable, it may be more difficult to control solder bridges between component pins. For solder mask for BGAs, many companies provide a solder mask that does not touch the pads, but covers any features between pads to prevent solder bridges. Most surface mount PCBs are covered with solder mask, but the solder mask coating, if the thickness is greater than 0.04mm (″), may affect the application of solder paste. Surface mount PCBs, especially those using fine pitch components, require a low profile photosensitive solder mask.

Solder mask window opening tips:

1.Solder mask opening for PCB pads

PCB pads are contacts that need to be surface mounted with electronic components, such as resistors, capacitors, ICs, etc. So PCB pads should not be printed with PCB ink.

This means that when you design a PCB, in the solder mask, you should create a solder mask opening for each PCB pad.

2.Solder mask opening for PCB through holes

Not all PCB through holes require solder mask openings,it all depends on your PCB needs.

For better heat dissipation, you can design solder mask openings for PCB through holes. Especially for power supply PCBs with high current flowing through them, solder mask openings for heat dissipation are common.

You can also fill the solder mask openings with tin, which acts as a metal heat sink.

PCB The solder mask opening of the through hole can also be used as a PCB test point. Because the copper is exposed, PCB testing can be performed here.

The above are two purposes of the solder mask opening of the PCB via. However, the solder mask can also be used in PCB through holes to protect the copper from oxidation, especially in corrosive environments.

3.Solder mask opening for gold fingers

PCB gold fingers are a row of exposed hard gold-plated pads on the edge of the PCB for plug-in connection. Gold fingers need to open solder mask because the solder mask acts as an insulator, while the gold fingers act as a connection and need to have good conductivity.

Without solder mask, there is no need to worry about gold finger oxidation. The PCB surface is hard gold plated, which protects the copper pad well.

4.Grounding solder mask opening

Solder mask openings can be designed for PCB grounding, and the exposed copper can be connected to the metal shell, so that the PCB is grounded.

5.Solder mask opening for measuring copper thickness

During the PCB manufacturing process, we need to measure the PCB copper thickness to see if it is qualified. Therefore, PCBONLINE may sometimes recommend solder mask openings to you based on your specific project.

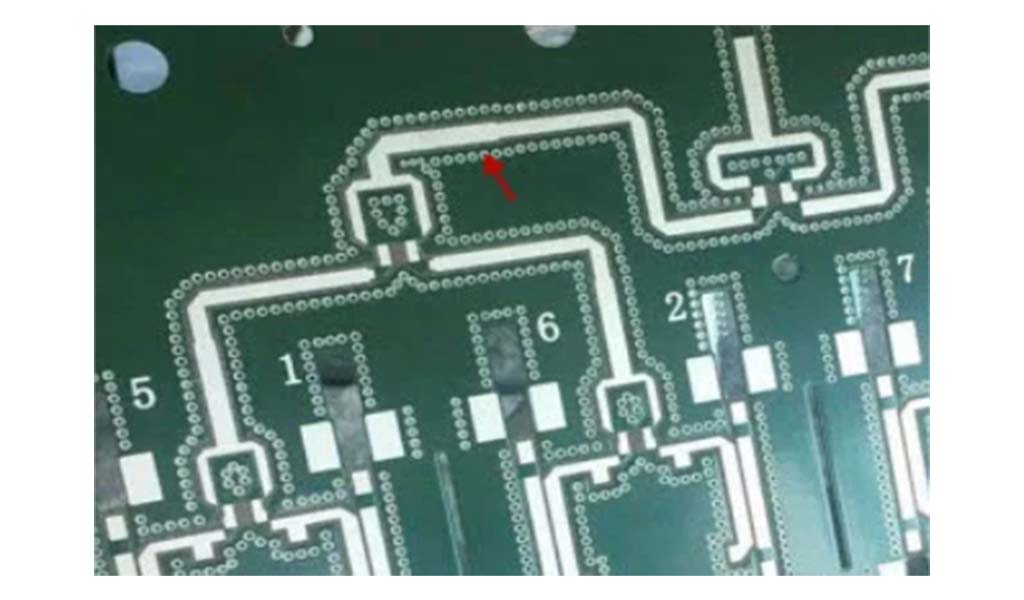

6.PCB Antenna solder mask opening

PCB antenna transmits and receives radio frequency microwaves, which consumes a lot of power. For high-frequency PCBs, it is common to open the solder mask layer of PCB antennas, because this way the antenna can consume less power.

When the solder mask opening size is too small, the pad will be covered by ink, resulting in a small welding area, which leads to poor welding; when the solder mask opening size is too large, it will cause the adjacent lines to be exposed, causing problems such as short circuits, and at the same time, the protective effect on the base copper will be reduced, accelerating the corrosion rate of the exposed part.

The size of the solder mask opening should be kept uniform as much as possible:

We know that the PCB package pads need to be opened in the solder mask layer. The solder mask opening means that the pad area cannot be covered by the green solder mask. In order to protect the PCB circuit from oxidation and short circuit during welding, our PCB outer layer is usually covered with a layer of solder mask. The commonly used solder mask is green oil (of course there are also black, red, yellow, blue and other oils).

However, green oil cannot be applied to the pad to avoid soldering tin. In order to prevent the solder mask from acting on the pad due to process tolerance, thereby affecting the solderability of the pad, we generally design the solder mask opening area larger than the pad, generally expanding it by 0.1 mm (4 mil). Of course, it is also possible not to expand it, so that the solder mask opening area is the same as the pad size, and the factory will handle it for you.

However, this requires that when making PCB packages,the size of the solder mask opening must be the same, such as the same size as the pad size, or 0.1mm larger than the pad size. If there are some external expansions of 0.05mm and some 0.1mm expansions, it will be more difficult for the factory to handle.