Solder wetting is a critical process in electronics manufacturing, particularly in the assembly of printed circuit boards (PCBs). It refers to the ability of molten solder to flow over and adhere to a metal surface, creating a strong, reliable electrical and mechanical connection. Understanding the principles and factors affecting solder wetting is essential for ensuring high-quality solder joints, which are vital for the performance and durability of electronic devices. This article delves into the science of solder wetting, its importance in PCB assembly, the factors influencing it, and best practices for achieving optimal results.

The Science of Solder Wetting

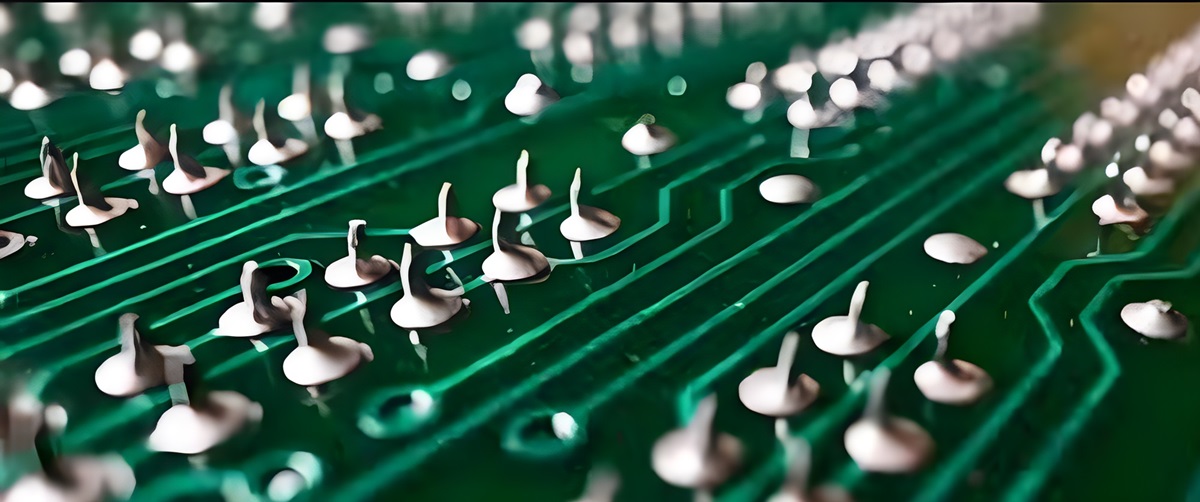

Solder wetting involves the interaction between molten solder and the surfaces to be joined. When solder is heated to its melting point, it transitions from a solid to a liquid state. In this liquid state, solder can spread across the surface of the metal pads and component leads on a PCB. The process of wetting is governed by surface tension and intermolecular forces between the solder and the substrate.

Surface Tension and Wetting Angle

Surface tension is a key factor in solder wetting. It is the cohesive force that causes the surface of a liquid to contract and resist external forces.When molten solder comes into contact with a metal surface, the balance between the surface tension of the solder and the adhesive forces between the solder and the metal determines the wetting angle.The wetting angle is the angle formed between the surface of the metal and the tangent to the solder surface at the point of contact. A smaller wetting angle indicates better wetting and stronger adhesion.

Intermolecular Forces

The intermolecular forces between the solder and the metal surface also play a crucial role. These forces include van der Waals forces, chemical bonding, and diffusion. When these forces are strong, the solder will spread more readily across the surface, resulting in better wetting.

Solder Wetting

Solder wetting is vital for several reasons:

Electrical Connectivity: Proper wetting ensures a reliable electrical connection between components and the PCB. Poor wetting can lead to intermittent connections or open circuits, compromising the functionality of the device.

Mechanical Strength: Good wetting creates strong mechanical bonds that can withstand physical stress and vibration. This is especially important for devices subjected to harsh environments or frequent handling.

Thermal Conductivity: Effective wetting enhances thermal conductivity, which is essential for dissipating heat generated by electronic components. Poor wetting can result in localized overheating and potential failure of the device.

Solder Joint Reliability: The reliability of solder joints is crucial for the long-term performance of electronic devices. Proper wetting reduces the risk of joint failure due to factors like thermal cycling, mechanical stress, and environmental conditions.

Factors Influencing Solder Wetting

Several factors influence the solder wetting process, including the properties of the solder, the substrate material, surface cleanliness, and soldering conditions.

Solder Composition

The composition of the solder alloy significantly impacts wetting. Common solder alloys include tin-lead (Sn-Pb), lead-free alternatives like tin-silver-copper (Sn-Ag-Cu), and specialized alloys for specific applications. Each alloy has unique properties that affect its wetting behavior, such as melting point, surface tension, and wettability.

Substrate Material

The material of the PCB and component leads also influences wetting.Common materials include copper, nickel, and gold. The compatibility between the solder alloy and the substrate material determines the strength of the intermolecular forces and, consequently, the quality of wetting.

Surface Cleanliness

Surface cleanliness is critical for effective solder wetting. Contaminants such as oxides, oils, and residues can hinder the interaction between solder and metal surfaces. Cleaning processes like flux application and surface preparation techniques are essential to remove contaminants and promote good wetting.

Soldering Conditions

Soldering conditions, including temperature, time, and atmosphere, play a significant role in wetting. The soldering temperature must be sufficient to melt the solder and allow it to flow. However, excessive temperatures can damage components and substrates. The duration of the soldering process must be carefully controlled to ensure proper wetting without overheating. Additionally, the soldering atmosphere, whether air or inert gas, can impact oxidation and wetting behavior.

Best Practices for Achieving Optimal Solder Wetting

To achieve optimal solder wetting, manufacturers must adhere to best practices in materials selection, process control, and quality assurance.

Material Selection

Choose the Right Solder Alloy: Select a solder alloy that is compatible with the substrate materials and meets the specific requirements of the application. Consider factors like melting point, mechanical properties, and environmental compliance.

Use High-Quality Components: Ensure that PCBs and components are sourced from reputable suppliers with consistent quality standards. High-quality materials reduce the risk of defects and improve overall wetting performance.

Process Control

Optimize Soldering Temperature: Carefully control the soldering temperature to ensure it is high enough to melt the solder but not so high as to damage components. Use precise temperature profiles for different soldering techniques, such as reflow soldering and wave soldering.

Control Soldering Time: Maintain an optimal soldering time to allow proper wetting without excessive heating. Monitor and adjust the process parameters to achieve consistent results.

Maintain Clean Surfaces: Implement effective cleaning processes to remove contaminants from surfaces before soldering. Use appropriate fluxes to promote wetting and prevent oxidation.

Use Controlled Atmosphere: Consider using an inert atmosphere, such as nitrogen, during soldering to minimize oxidation and improve wetting. This is particularly important for lead-free soldering, which is more susceptible to oxidation.

Quality Assurance

Inspect Solder Joints: Perform thorough inspections of solder joints using techniques like visual inspection,X-ray imaging, and automated optical inspection (AOI). Identify and address any defects to ensure the reliability of the solder joints.

Conduct Reliability Testing: Perform reliability testing, such as thermal cycling and mechanical stress tests,to evaluate the long-term performance of solder joints. This helps identify potential issues and validate the effectiveness of the soldering process.

Implement Process Controls: Use statistical process control (SPC) methods to monitor and control the soldering process.Track key parameters and implement corrective actions as needed to maintain consistent quality.

Conclusion

Solder wetting is a fundamental aspect of electronics manufacturing that directly impacts the performance and reliability of electronic devices. By understanding the science behind solder wetting and the factors that influence it,manufacturers can implement best practices to achieve optimal results. Proper material selection, process control, and quality assurance are essential for ensuring strong, reliable solder joints that meet the demands of modern electronics. As technology continues to advance, the importance of solder wetting will only grow, making it a critical area of focus for the electronics industry.