Inside the power module of the new energy vehicle charging pile, a palm-sized light green colored substrate carries dozens of semiconductor devices.When the charging current reaches 250A, the surface temperature of this seemingly ordinary circuit board is always stabilized below 85℃,which is the engineering miracle created by ceramic PCB technology.With the 5G base station power density breakthrough 200W/cm², spacecraft electronic systems face more than 200 ℃ extreme environment,the traditional organic substrate has been unable to meet the demand for ceramic PCB is becoming the core support material for high-end electronic equipment.

Aluminum oxide (Al₂O₃) substrate as the first generation of ceramic PCB materials, its 96% purity model of thermal conductivity up to 24W/(m-K), cost control in the ordinary FR4 substrate 3-5 times. In the field of industrial inverters, this material supports the stable operation of IGBT modules at 10kHz frequency for more than 50,000 hours. Test data from a well-known elevator manufacturer shows that the failure rate of control modules with alumina substrates is 47% lower than that of traditional materials.

The thermal conductivity of aluminum nitride (AlN) substrate jumps to 170-220W/(m-K), and the coefficient of thermal expansion (4.5ppm/°C) is a near-perfect match with silicon chips. In the LIDAR transmitter module, the AlN substrate successfully controls the junction temperature of the pulsed laser within 70°C, increasing the detection range by 30%. However, the material cost remains high, with the price of a single piece being 8-10 times higher than that of an aluminum oxide substrate.

Beryllium oxide (BeO) substrate was once 330W/(m-K) thermal conductivity, but its highly toxic properties gave birth to a new type of composite materials. An AlN-SiC composite substrate developed by a military industrial unit was successfully applied to the T/R component of airborne phased array radar by increasing the bending strength to 450MPa while maintaining the thermal conductivity of 250W/(m-K).

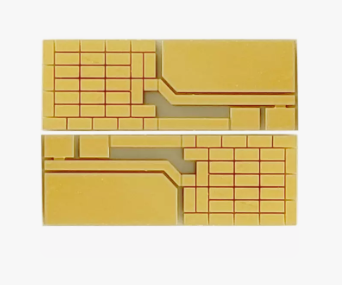

Epitaxial molding process, the particle size of 200nm ceramic powder and organic solvents mixed in the ratio of 7:3, in the precision of ± 1μm scraper to form a 0.25mm thick billet strip. A Japanese company's production line data show that by controlling the drying temperature at 35 ± 2 ℃, the moisture content of the raw blank can be stabilized at 0.8% or less, sintering shrinkage fluctuations controlled at ± 0.3%.

Thick film technology using screen printing, silver palladium conductor line width accuracy of ± 15μm, resistance paste by 850 ℃ sintering square resistance can be controlled at 10mΩ / □. In the OBC module of new energy vehicles, the power line made by this process successfully carries 100A continuous current with a temperature rise of no more than 40K.

The laser processing system uses a 355nm UV laser to make microvias with a diameter of 80μm on a 0.5mm-thick AlN substrate, with a hole position accuracy of ±5μm. Tests by a semiconductor equipment vendor show that this drilling process reduces high-frequency signal transmission loss by 0.2dB/cm@10GHz.

In thermal stress tests, the Al₂O₃ substrate maintains a surface metallization layer bonding force of greater than 15N/mm after undergoing 2,000 cycles of -55°C~150°C. Accelerated aging experiments by a photovoltaic inverter manufacturer show that the insulation resistance of ceramic PCB modules decreases by only 8 percent after working for 5,000 hours in an 85°C/85% RH environment.

High-frequency characterization tests show that the dielectric loss angle tangent of the AlN substrate at 40 GHz is still below 0.0005, which keeps the millimeter-wave radar's antenna feed network insertion loss within 0.3 dB. A communication equipment vendors of measured data show that the use of ceramic substrate 28GHz base station amplifier efficiency by 5 percentage points.

In the military field, special ceramic PCB needs to withstand 20g vibration acceleration and 1000g mechanical shock test. The guide head circuit board of a certain type of missile adopts corrugated structure design, and the bending strength is increased to 300MPa while maintaining the heat dissipation capacity of 15W/cm².

In the intelligent management system of an energy storage power station in Shenzhen, the monitoring module equipped with ceramic PCB has been running continuously for 3 years, with accumulated data processing exceeding 2 PB.These ceramic substrates hidden in industrial equipment are supporting modern electronic technology to advance to a higher power density and more severe environmental adaptability with a dimensional accuracy of 0.001mm and a temperature control accuracy of 0.1°C. The ceramic substrates are also used to control the temperature of the power station and the power supply of the power station, and to control the temperature of the power station. With the breakthrough of low-temperature co-fired ceramic (LTCC) technology, three-dimensional ceramic circuit structures are opening up new dimensions of high-frequency system integration, and this silent material revolution continues to evolve.