PCB surface treatment processes include: OSP, tin, lead-free tin, gold plating, tin deposition, silver deposition, hard gold plating, full board gold plating, gold fingers, nickel palladium OSP, etc.

Gold plating and gold plating are commonly used processes in PCB circuit board. Many engineers are unable to accurately distinguish between the two, so today we will summarize the differences between the two.

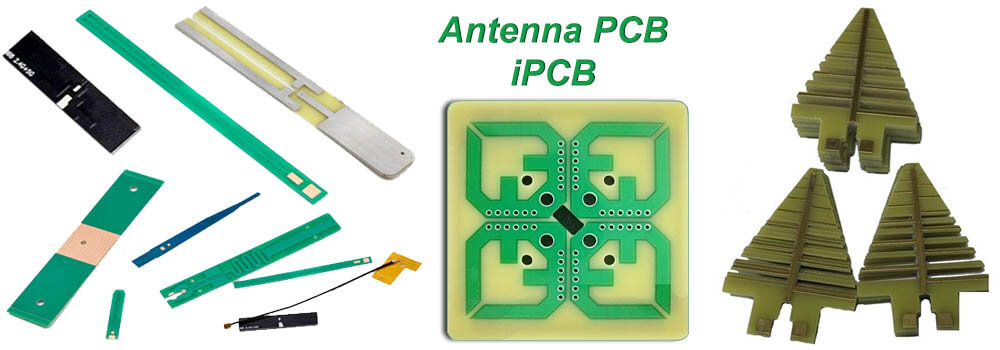

High frequency antenna circuit board

Is the PCB circuit board gold-plated?

We call whole board gold plating, which generally refers to "electroplated gold", "electroplated nickel gold plate", "electrolytic gold", "electroplated gold", "electroplated nickel plate". Soft gold and hard gold are different (ordinary hard gold is used for gold fingers).

The principle is to melt nickel and gold (commonly known as gold salts) into a chemical solution, immerse the circuit board in a plating bath, apply current, and form a nickel gold coating on the copper foil surface of the circuit board.

Nickel metal fittings are widely used in electronic products due to their high hardness, wear resistance, and resistance to oxidation.

Scorpion is divine gold? Sinking gold is a layer of coating formed through chemical oxidation-reduction reactions. The common thickness is relatively thick. It is a chemical nickel gold deposition method that can achieve thicker gold layers.

The difference between gold EING and gold-plated PCB board

1. Ordinary immersion gold is much thicker than gold plating, and immersion gold will turn golden, even more yellow than gold plating. Seeing the customer's appearance, Chen Jin was even more satisfied. The crystal structures formed by the two are different.

2. Due to the different crystal structures formed by immersion and gold plating, immersion is easier to solder than gold plating, and will not cause poor soldering or customer complaints. Meanwhile, because gold is softer than gold-plated, gold finger plates are usually gold-plated, hard and wear-resistant.

3. The sinking gold plate only has nickel gold on the solder pads, and the signal transmission in the skin effect is not affected by the copper layer.

4. Compared to gold plating, gold has a finer and more precise crystal structure, and is less likely to produce oxygen.

5. As the wiring becomes denser, both the line width and spacing reach 3-4MIL. Gold plating is prone to short circuiting of gold wires. The gold-plated pad only has nickel gold, so there will be no short circuit of gold wire.

6. The sinking gold plate only has nickel gold on the solder pads, so the solder joints on the circuit are more firmly bonded to the copper layer. The repayment of the project does not affect the spacing.

7. Generally used for wrenches with high precision. Better flatness. Usually, it is considered appropriate to use immersion gold. After assembly, the sunk gold will not expose the black solder pads. The flatness of the sunken gold plate is comparable to that of the gold plate, and it can be used for a lifetime.

8. The price of gold in the market is extremely expensive. Many manufacturers are unwilling to produce gold-plated plates in order to save costs, and only gold-plated plates with nickel gold on the solder pads are indeed much cheaper. Other statements: 1 Deep gold plate and gold plate are the same process products. Electric hot stamping plate and flash hot stamping plate are also products of the same process. In fact, they are just alternative people in the PCB industry. Electronic gold plates are more common in mainland China, while in Taiwan they are mostly gold plates and flash gold plates.

9. Sunken gold plate/gold-plated plate is generally referred to as chemical nickel plating plate or nickel gold plating plate. The growth of nickel/gold layer is considered suitable and is electroplated in the form of chemical deposition.

10. Gold plating/flash gold plating is generally more formally called electroplated nickel gold plating or flash gold plating. The growth of nickel/gold layer is considered suitable and is electroplated through DC electroplating.

IPCB is a PCB manufacturing factory in China, specializing in the production of radio (microwave) frequency PCB board, HDI PCB multilayer board, blind buried PCB, rigid flexible PCB, and more. We produce OSP circuit board, tin coated circuit board, gold-plated circuit board, tin plated circuit board, silver plated circuit board, hard gold plated circuit board, full board gold-plated circuit board, gold finger circuit board, nickel palladium circuit board, etc.