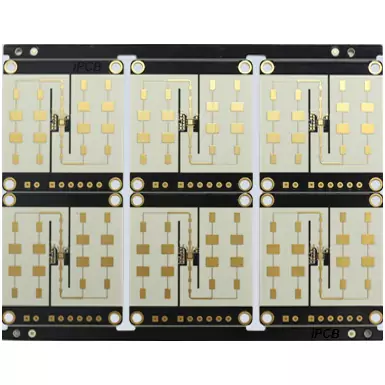

Substrate: Taconic RF-35 PCB

Material: Taconic RF-35

Dielectric constant: 3.5

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.762mm (20mil)

Finished product thickness: 0.85mm

Solder mask color: Black

Screen color: None

Surface treatment: immersion glod

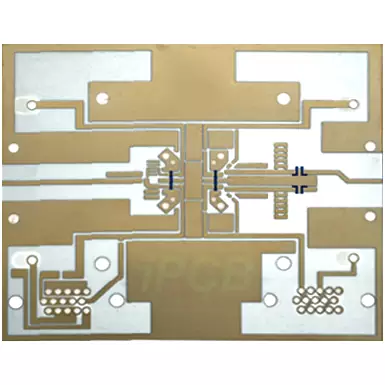

Product application: Communication

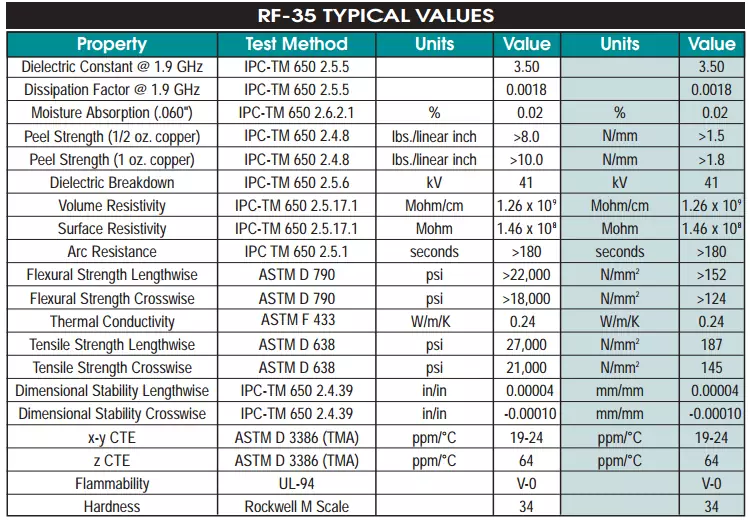

RF-35 is an organic ceramic high-frequency circuit material in the Taconic ORCER series products. RF-35 is based on woven glass reinforcement and ceramic filling technology. RF-35 is the best choice for low-cost, large-scale commercial microwave and radio frequency applications. The peel strength of 1/2 ounce and 1 ounce copper is excellent (even compared to standard epoxy resin materials). RF-35 has ultra-low moisture absorption and low dispersion coefficient, minimizing phase shift with frequency to the greatest extent possible.

Taconic RF-35 and RF-35A2 are organic ceramic high-frequency circuit materials suitable for RF and microwave applications. RF-35A2 has lower losses and higher thermal conductivity, making it suitable for applications with high frequency and heat dissipation requirements.

Taconic RF-35

What is the difference between RF-35 vs RF-35A2?

Taconic RF-35

Material: Organic ceramic high-frequency circuit material, based on woven glass reinforcement.

Dielectric constant (DK): 3.5

Loss factor (DF): 0.0018

Thickness options: 0.254mm, 0.508mm, 0.762mm, 1.524mm, etc.

Advantages: Low cost, excellent peel strength, extremely low dissipation coefficient, low moisture absorption, enhanced surface smoothness.

Application areas: power amplifiers, filters and couplers, passive components.

Taconic RF-35A2

Material: RF and microwave high-frequency circuit material, with a minimum loss of 3.5 DK substrate.

Loss factor (DF): 0.0011 (lower than RF-35)

Dielectric constant (DK): 3.5+/-0.05 (with stricter tolerances)

Thickness options include 0.13mm, 0.25mm, 0.51mm, 0.76mm, 1.52mm, etc.

Characteristics of RF-35A2

Improved thermal conductivity, thereby enhancing power processing capability.

The structural design allows for easier drilling.

Low dissipation factor and excellent copper peel adhesion performance.

Difference between RF-35 vs RF-35A2

Loss factor: RF-35A2 has a lower loss factor (0.0011), while RF-35 has a loss factor of 0.0018. This means that RF-35A2 may provide better signal transmission performance in high-frequency applications.

Tolerance of dielectric constant: The dielectric constant of RF-35A2 has a stricter tolerance range (3.5+/-0.05), which may make it more suitable for applications that require precise control of electrical characteristics.

Thermal conductivity: RF-35A2 has a higher thermal conductivity, which helps to handle higher power and is suitable for applications that require better heat dissipation.

The similarities between RF-35 and RF-35A2

RF-35 and RF-35A2 both belong to Taconic's ORCER product line and are organic ceramic high-frequency circuit materials designed for high-performance RF and microwave applications.

RF-35 and RF-35A2 all have similar dielectric constants (DK of 3.5), indicating that they have similar fundamental characteristics in electrical performance.

RF-35 and RF-35A2 both use ceramic filling technology and coated PTFE glass fibers, which provide them with excellent electrical and mechanical properties

Substrate: Taconic RF-35 PCB

Material: Taconic RF-35

Dielectric constant: 3.5

Base copper thickness: 18um (0.5oz)

Finished copper thickness: 35um (1oz)

Medium thickness: 0.762mm (20mil)

Finished product thickness: 0.85mm

Solder mask color: Black

Screen color: None

Surface treatment: immersion glod

Product application: Communication

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.