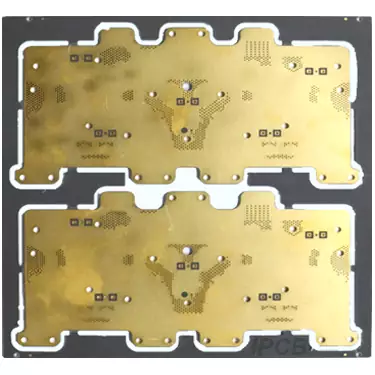

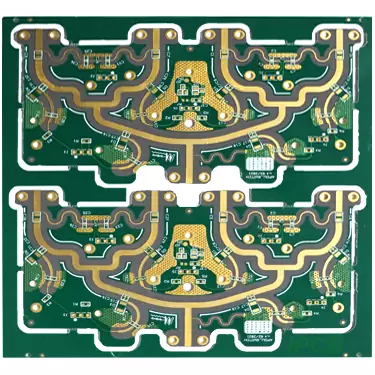

Material: Taconic TLY-5

Layer: 1L-16L

TLY-5 dk: 2.2

TLY-5 df: 0.0009

Base copper thickness: 0.5oz

Outer copper thickness: 1oz

TLY-5 thickness: 10mil, 20mil, 30mil, 60mil

Solder mask colors: green, red, blue

Surface treatment: Immersion silver, Gold

Application: Microstrip line, radar, missile

Taconic TLY-5 RF PCB board is made of very lightweight textured glass fiber and PTFE, which is more stable in size than short cut fiber reinforced PTFE composite materials. The textured matrix in TLY-5RF PCB material can produce circuit boards with higher mechanical stability, suitable for large-scale manufacturing. Low dissipation factor can be successfully deployed in automotive radar applications designed at 77 GHz and other antennas at millimeter wave frequencies.

Taconic TLY-5 features: extremely low DK substrate, stable size, lowest DF, low moisture absorption rate, high copper peel strength, uniform DK, laser ablation capability.

Taconic TLY-5 applications: automotive radar, satellite/cellular communication, power amplifier, LNB, LNA, LNC, aerospace, Ka, E, and W-band applications.

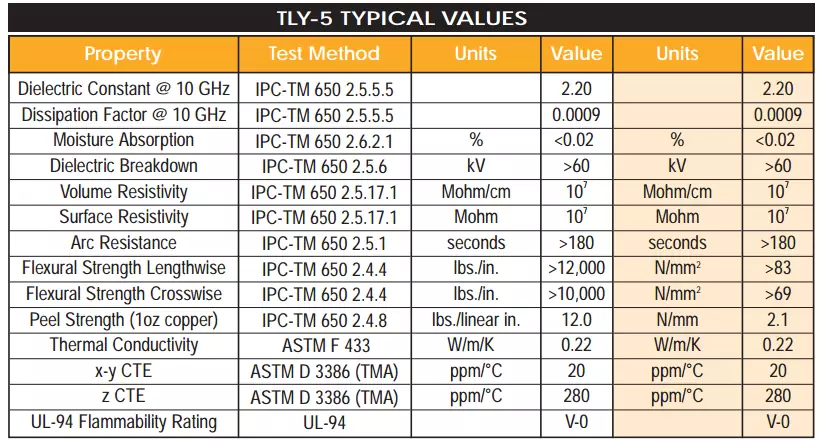

Taconic TLY-5 Datasheet

Taconic TLY-5 vs Rogers 5880

Taconic TLY-5 and Rogers 5880 are two common high-performance high-frequency circuit board materials in the market, often used for high-frequency and microwave applications. Although they have similar technical specifications, there are still subtle differences in practical applications.

From an electrical performance perspective, both Taconic TLY-5 and Rogers 5880 have low dielectric constants (Dk=2.2) and loss factors (Df=0.0009), making them highly suitable for applications up to millimeter wave frequencies. However, depending on the specific frequency and application, there may be slight differences in the response of these two materials. For example, TLY-5 performs better in high humidity environments and applications that require precise size control due to its extremely low water absorption rate and superior structural stability.

Considering physical properties and processing conditions, TLY-5 is made of textured glass fiber, providing higher mechanical stability and suitable for large-scale production. Rogers 5880 is known for its excellent copper foil adhesion and processing flexibility. In addition, the inventory status and delivery cycle of PCB manufacturers are also factors that designers need to consider when selecting materials. The ordering cycle of Taconic TLY-5 and Rogers 5880 also affects the final choice of high-frequency circuit board customers.

From the perspective of application scope, both Taconic TLY-5 and Rogers 5880 have a wide range of applicability, from aerospace to automotive radar systems, to communication equipment. However, depending on specific design requirements and the intended use of the final product, one material may be more suitable for a particular application scenario than another.

Although Taconic TLY-5 and Rogers 5880 share similar characteristics in multiple aspects, they still demonstrate their unique advantages in practical applications. The choice of material depends on specific design requirements, budget constraints, and supply chain considerations.

Material: Taconic TLY-5

Layer: 1L-16L

TLY-5 dk: 2.2

TLY-5 df: 0.0009

Base copper thickness: 0.5oz

Outer copper thickness: 1oz

TLY-5 thickness: 10mil, 20mil, 30mil, 60mil

Solder mask colors: green, red, blue

Surface treatment: Immersion silver, Gold

Application: Microstrip line, radar, missile

iPCB Circuit provides support for PCB design, PCB technology, and PCBA assembly. You can request technical consultation or quotation for PCB and PCBA here, please contact email: sales@ipcb.com

We will respond very quickly.