The 5G RF PCB market is large.In 2019, the global PCB output value was 54.2 billion US dollars, and the industry's growth rate in the past five years did not exceed 3%. Countries and regions competing in PCB industry include the United States, Europe, Japan, Chinese Mainland, Taiwan, South Korea, etc. In 2016, the output value of PCB in Chinese Mainland reached US $27.01 billion, accounting for 50% of the world. Market forecast shows that China will become the region with the fastest growth in PCB production in the next five years. By 2020, the market size will reach 35.9 billion US dollars, with a compound annual growth rate of approximately 3.1%.

The upstream of the PCB industry is copper plates, while the downstream covers all circuit products. The proportion of PCB demand for communication equipment, computers, and consumer electronics products is 28% 8%, 265%, and 14%. They account for 3% and nearly 70% of the total demand respectively, making them the three regions with the highest PCB demand. It is expected that from 2017 to 2021, communication equipment and automotive electronics will become new driving forces for the development of the PCB industry, with compound annual growth rates of 7% and 6%, respectively. The applications of communication network construction in PCB mainly include wireless networks, transmission networks, data communication, and fixed broadband. In the early stages of 5G construction, high-frequency boards and high-speed multi-layer boards are large.

The value of base station PCB will significantly increase

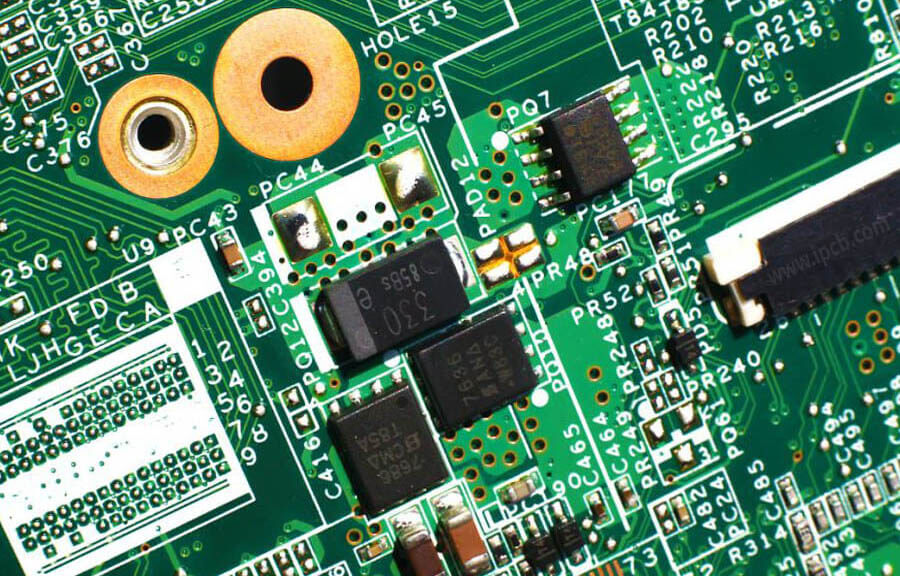

The application of massive MIMO in the 5G era has brought about significant changes to the structure of base stations. The antenna+RRU+BBU has been transformed into an AAU+BBU (Cu/DU) architecture. In AAU, the antenna oscillator and micro transceiver unit array are directly connected to the printed circuit board, which integrates digital signal processing modules (DSP), digital to analog converters (DAC)/analog-to-digital converters (ADC), amplifiers (PA), low-noise amplifiers (LNA), filters and other devices as RRU functions.

The requirement for antenna integration has significantly increased. AAU needs to integrate more components in a smaller size and use more layers of PCB technology. Therefore, the PCB consumption of a single base station will significantly increase. The process and raw materials need to be comprehensively upgraded, and the technological barriers will also be comprehensively upgraded. The transmission power of 5G base stations is much greater than that of 4G, which requires a comprehensive upgrade of the PCB substrate, such as high frequency PCB, high speed PCB, good heat dissipation performance, small and stable dielectric constant, moderate loss, consistent with thermal expansion, copper foil coefficient as low as possible, low water absorption rate, other heat resistance, chemical resistance, impact strength, peel strength, etc. Printed circuit boards.

Different materials result in different processing techniques. The same PCB needs to achieve multiple functions, and different materials are mixed. Therefore, the value of PCB will be further enhanced.

The volume and quantity of BBUs have not changed much, but due to the increase in transmission rate and the decrease in transmission delay, the demand for RF information processing capability of BBUs has increased, and the demand for high-speed PCBs has greatly increased. The core configuration of BBU is one backplane and two single boards (main control board and baseband board). Backplane is mainly used to connect single boards and achieve signal transmission. It has the characteristics of high multilayer, ultra large size, ultra-high thickness, overweight, and high stability. This is a very difficult problem to handle. It is the PCB with the highest unit price for base stations. The single board is responsible for RF signal processing and RRU connection, mainly using high-speed multi-layer PCBs. With the increase of high-speed data exchange scenarios in the 5G era, the quantity and consumption of high-speed material backboards and veneers will further increase. The number of layers on the back and single board will increase from 18 to 20 and then to 30. Copper laminates need to be upgraded from traditional FR4 materials to high-performance high-speed materials such as M4/6/7, thereby increasing the price per square meter.

Calculation of Market Space for Base Station Circuit Boards

According to market data, 4G data circuits and RF account for about 60% of the RRU area, and the PCB area of 4G base station data circuits and RF is about 0.2m2. However, with the increase in AAU data transmission and processing in the 5G era, the area of data circuits and RF PCBs is expected to double, to around 0.4m2. Due to the integration of the base station feeding network and antenna oscillator on the PCB, the area of the feeding network and antenna oscillator is approximately equal to the area of the motherboard. According to Huawei's data, the main station area and height of the 64r64r base station are 0.6m and 0.4m, respectively. Therefore, the area of the antenna element and feeding network is about 0.5m2. The PCB area of the 5G base station AAU is about 0.9m2, which is 4.5 times the PCB area of the 4G era.

In addition, there are more oscillators in the antenna array, arranged more tightly. Therefore, the substrate of the antenna array requires high-quality PCBs. By optimizing the radiation element and array mode, mutual impedance can be reduced and overall efficiency can be improved. With the increase of massive MIMO channels, the area and number of layers per PCB will also increase from 15 square centimeters to 35 square centimeters. The number of layers has been upgraded from double-sided panels to around 12, and the substrate requires high-speed and high-frequency materials. According to market data, the unit price of 5G PCB is around 2000 yuan per square meter. Assuming each base station has three antennas, the estimated cost of a printed circuit board for a single base station is around 6000 yuan. Assuming that the unit price of large-scale production decreases by 5% year by year, it is expected that the PCB market space required for building base stations by 2026 will be about 29%. 2 billion yuan. If we consider the number of global 5G base stations, the demand for Du, Cu, backplane, and small base station construction will be greater.