As technology advances and equipment becomes more sophisticated, the reliability and performance of PCB increase. However, to ensure these performances, the setup of test points is particularly important. So, how should the number of PCB test points should be determined, and what role they have?

First, the role of test points

Test points are PCB nodes specifically designed for testing and debugging, mainly the following roles:

1.Fault diagnosis: test points can help engineers quickly diagnose problems in the circuit. By setting up test points at key nodes, it is easy to measure signal levels, detect voltage changes and find failure points.

2.Functional verification: In the production line, test points are used to verify whether the function of the PCB meets the design requirements. By connecting the test equipment, engineers can detect whether each functional module works properly.

3.Quality Control: Test point is an important part of quality control. By testing each PCB, it ensures that the product meets the quality standards before delivery and reduces rework and repair costs.

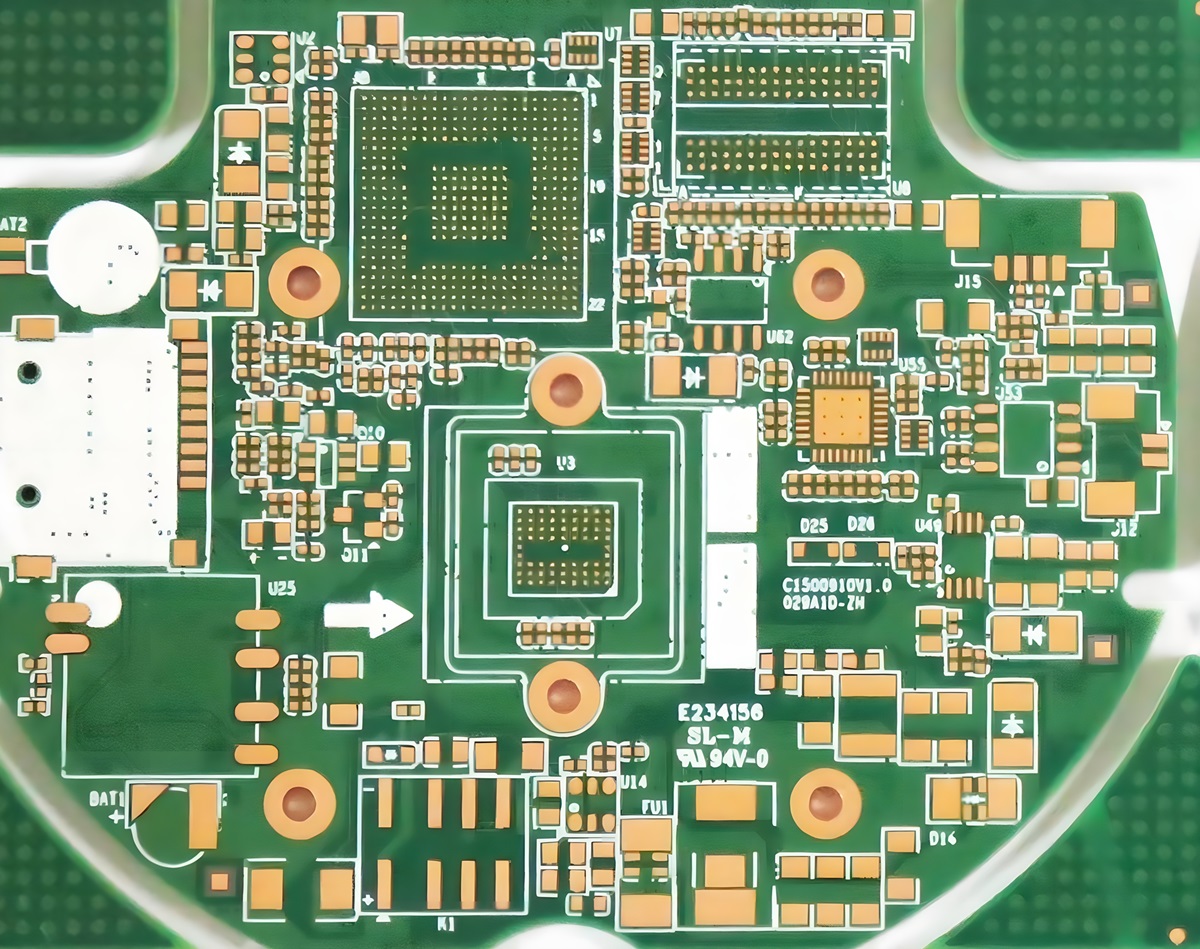

PCB test points

Second, determine the number of test points

In determining the number of test points, the designer needs to consider the following factors:

1.Circuit complexity: complex circuits usually require more test points to cover all critical functions and signal paths to ensure comprehensive testing.

2.Testability: In the design process, it is critical to consider testability. Engineers need to weigh the number and location of test points to ensure that the circuit performance does not affect the premise of the test points can be effectively signal acquisition and monitoring.

3.Cost-effective: increasing test points will increase the PCB manufacturing costs and test time. Therefore, engineers need to find a balance between meeting the test requirements without increasing excessive costs.

4.Design specifications and standards: different industries and applications may have different design specifications and standards, and need to determine the number of test points according to specific requirements.

Third, industry experience sharing

In practice, some experienced engineers have shared their insights on test points in PCB design:

1. Prioritise the coverage of the critical path: In the layout of the test points, priority should be given to covering the critical path and problem-prone parts. This can improve the efficiency and effectiveness of testing.

2. The use of automated test equipment: With the help of automated test equipment, you can significantly improve the speed and accuracy of testing. At the same time, automated equipment can also reduce human intervention, reducing the possibility of human error.

3. Continue to optimize the design: The design of the test point is not static. In the process of product iteration and upgrading, the layout and number of test points also need to be continuously optimized to adapt to new features and new technologies.

In short, rational design of the number and location of PCB test points is critical to ensure product quality and improve productivity. Engineers need to fully consider these factors at the design stage to achieve optimal design results.

All in all, test points can help us find problems in time during the production process. Through test point inspection, we can quickly locate faults and prevent defective products from reaching the market. In addition, test points can also provide diagnostic information during the use of the product, helping maintenance personnel to quickly find the cause of the failure. Finally, test points are also crucial for product quality control. By regularly inspecting test points, we can ensure that our products maintain good performance throughout their life cycle.