With the continuous expansion of global data center scale and the rapid growth of AI accelerated computing demand, optical modules are playing an unprecedented important role as high-speed interconnection bridges between servers and switches. From 25G and 100G to 400G and 800G optical modules, their high-speed electrical interfaces require higher signal integrity, reliability, and processing technology for PCB.

In the highly integrated system of optical modules, PCB is not only the carrier of circuits, but also the key infrastructure that determines high-speed link performance and module stability.

The Core Role of PCB in Optical Modules

High-speed differential signal transmission: Connecting core ICs such as DSP, CDR, TIA, and laser driver.

Power isolation and noise suppression: Stabilizing and isolating multiple power supplies from interference.

Thermal management and heat dissipation path construction: Ensuring long-term operation of the module under high-power environments.

Mechanical and structural support for the photoelectric conversion area: Maintaining device positioning accuracy and overall module reliability.

With the rapid increase in optical module speeds, the material properties, layer stack-up structure, and processing capabilities of the PCB have become key factors affecting link performance.

Commonly Used PCB Materialsand Layer Stack-up Designs for High-Speed Optical Modules

To meet the requirements of high-speed signals such as 56G/112G PAM4, the industry has gradually transitioned from traditional FR4 to low-loss materials:

| Module Rate | Recommended Material | Dielectric Constant Dk | Loss Tangent Df | Features |

|---|---|---|---|---|

| 25G | High Tg FR4 | 4.2 | 0.01 | Low cost, suitable for mid-speed links |

| 56G | S1000H / MEGTRON 6 | 3.4 | 0.003 | Low loss, industry mainstream |

| 112G | Tachyon 100G / I-Speed | 3.2 | 0.002 | Ultra-low loss, high manufacturing requirements |

The typical characteristics of a stacked structure include:

The high-speed layer adopts ultra-thin dielectric (reducing wiring loss)

Laser blind holes and buried holes meet high-density interconnection requirements

Backdrill reduces reflection caused by residual stubs in via holes

Multi layer design for EMI suppression

These designs collectively ensure that the insertion loss and return loss of high-speed links meet the requirements of the IEEE 802.3 series standards.

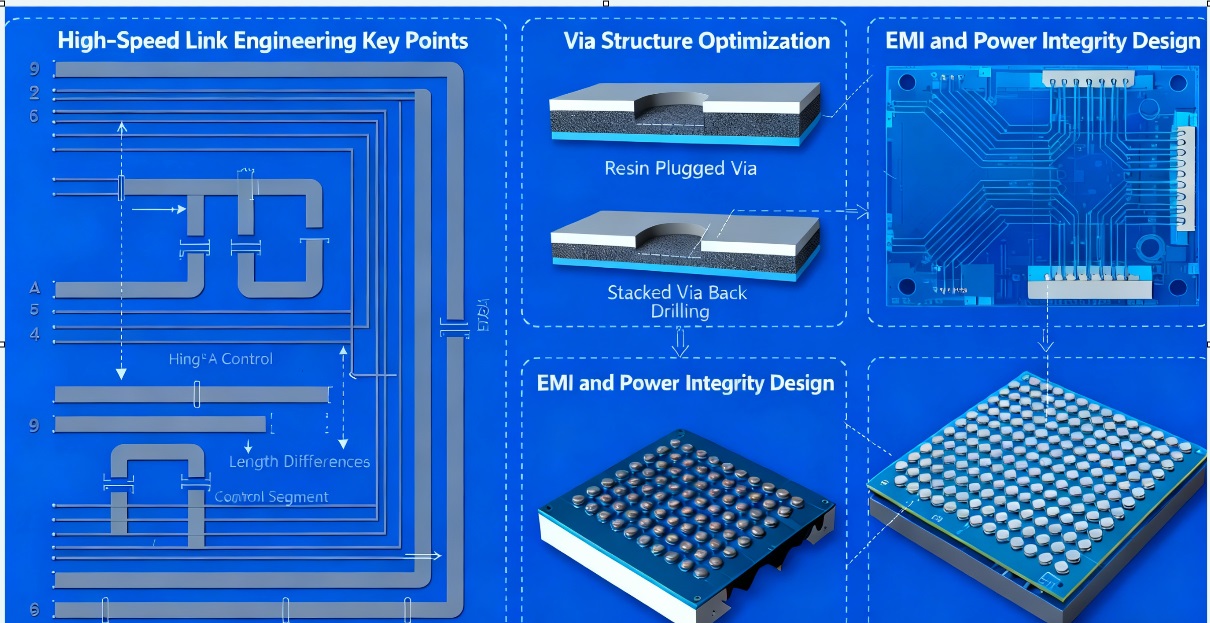

Optimization of via structure

Differential routing design

Accurate impedance control (typically 85 Ω± 5%)

Control the length difference at the sub mil level

Using circular arcs or a 45 ° angle to avoid excessive radiation caused by a 90 ° angle

Optimization of via structure

High speed signals are extremely sensitive to vias, so the industry generally adopts:

Type VII resin filled via

Stacked via for high-density packaging

Backdrill eliminates through-hole stubs to improve reflection performance

Key points of high-speed link engineering design

EMI and power integrity

Power partition isolation

Local shielding cover is used in high-frequency areas

Surrounding ground via array (GND stitching)

Special requirements of PCB for different optical module structures

The packaging forms of optical modules are diverse, and the internal structural differences directly affect the PCB design method.

COB (Chip On Board) solution

Key features:

DSP/TIA bare chip directly soldered onto PCB

The requirement for solder mask accuracy is extremely high

The gold wire has a short span and strict requirements for geological layout

ACO (Active Cooled Optics) solution

Suitable for scenarios with extremely high temperature control requirements:

Add TEC and NTC related layouts

Strengthen the design of metal heat dissipation paths

PCB needs to ensure stability under thermal stress

TO-CAN packaging solution

Key Features:

Strict requirements for coaxial shielding structure

High frequency devices need to be arranged nearby

Grounding design must maintain extremely low impedance

Thermal Design and Structural Reliability

The overall size of the optical module is small and the power density is high, making the thermal management capability of the PCB crucial.

Thermal design measures include:

Thermal conductivity between large-area copper foil and copper-clad islands

Design of Via in Pad with Multiple Via Arrays

Increase the coupling efficiency of thermal interface materials (TIM)

Reliability enhancement measures:

Select substrates with excellent CAF performance

Moisture resistant design (solder mask material, edge sealing)

Golden Finger adopts ENIG/ENEPIG technology to improve the insertion and removal life

The future development direction of optical module PCB

Driven by the demand for high-speed interconnection between AI data centers and the next generation, optical module PCBs are evolving in the following directions:

Lower loss materials: LCP, mSAP, ABF substrates will gradually become popular

Higher Density Interconnection (HDI/SLP): Suitable for module heights below 1.0 mm

Optoelectronic Hybrid Integration (CPO): Deep Collaboration between PCB and Light Engine

Higher automation production and quality control: supporting consistency at the million wafer level