FPC stiffener board plays an important role in providing mechanical support for FPC, because FPC flexible circuit boards are flexible, but rigidity is required in certain places.

Reinforcement boards are especially needed when components are placed in the flexible area of the FPC, and the weight of these components stresses the flexible material. They can also be used where you need to create a rigid circuit board surface to place SMT pad components. In addition, connectors that require multiple inserts need reinforcement to reduce stress on the pads. Let's understand the use of reinforcement boards in more detail.

What are the various uses of FPC stiffener boards?

Simply put, reinforcement reinforcement boards are used where a certain area of the FPC flexible circuit board needs to be stiffened. Here are some common reasons for using reinforcement:

1. Support area of the board with SMT or PTH components.

2. Maintain a reasonable thickness of the flexible circuit.

3. Support PCB connectors.

4. Ensure better handling of the board.

5. Ensure that the board area remains stable.

6. Help with routing and retaining arrays.

7. Help eliminate strain and effectively dissipate heat.

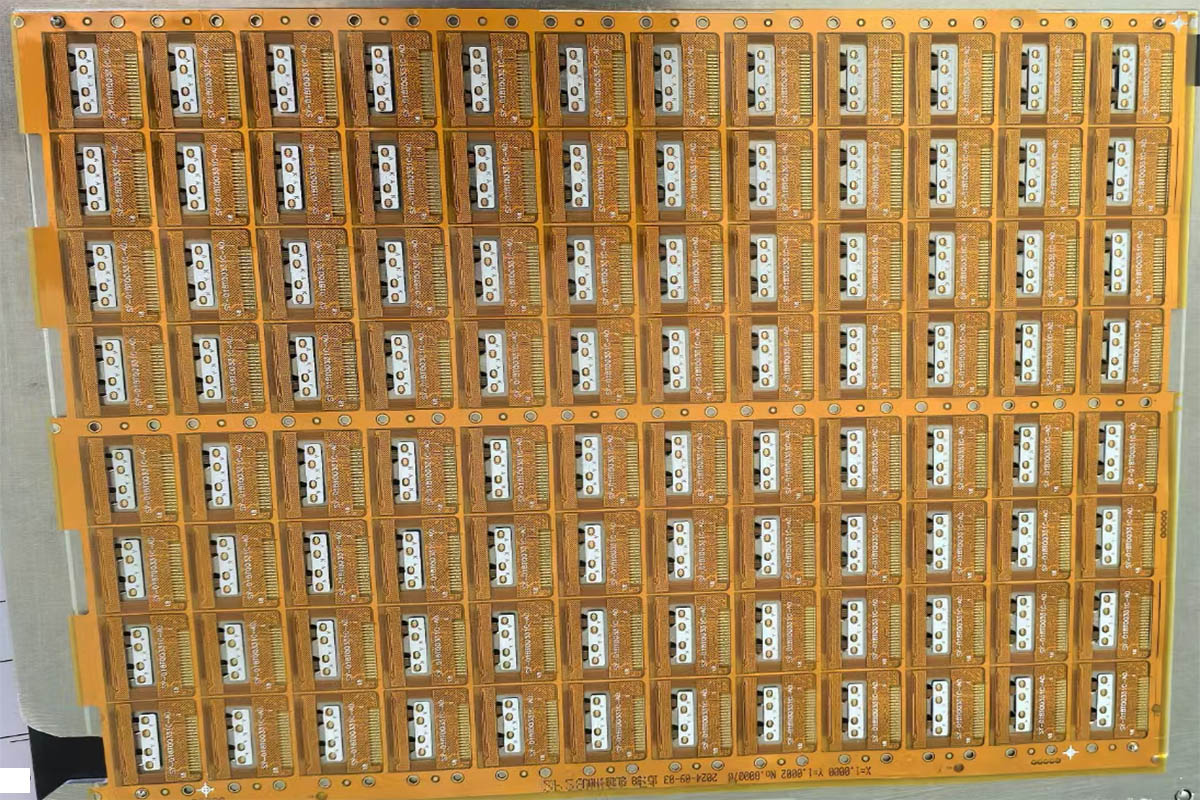

FPC stiffener board

Generally speaking, flexible PCB stiffener requirements are divided into the following usage categories:

1. Hardened component/connector area

2. ZIF (zero insertion force) thickness requirements

3. Local bending constraints

4. Component/connector reinforcement

FPC stiffeners create a rigid area that connects components and connectors. They also protect solder joints by ensuring that the flex does not bend in the component area. FPC stiffeners ensure that the thickness at the contact fingers is increased to meet specific connector specifications.

How to choose the right FPC stiffener material?

FPC stiffeners are typically composed of FR4 or rigid polyimide.

Typical reinforcement thickness ranges from 0.002" to 0.059". The thickness of the reinforcement ranges from 0.002" to 0.010", and the thickness of the rigid reinforcement ranges from 0.008" to 0.059". Generally speaking, the thicker the FPC stiffener, the better support it provides. However, the requirements of each design are different.

Some use cases also require the use of stainless steel or aluminum as FPC stiffeners. Of course, the downside to using these tools is that they are too expensive.

How to use FPC stiffener boards?

In the case of plated through-hole components, the FPC stiffener board is located on the same side of the flexible board as the component. This makes it easier to access the pads on the flexible circuit.

It is also possible to attach reinforcements to both sides of the part, but in this case, the PCB assembly requires an array configuration review.

When the FPC flexible circuit design requires assembly panelization, it is recommended to use FR4 reinforcement boards across the entire array boundary. This way, no additional tool boards are required. In addition, it allows the part to pass automated assembly like a rigid circuit board.

When attaching reinforcements to the loop, heat and pressure are required. Pressure-sensitive adhesives can also be used to attach FPC stiffener boards.

Two popular adhesives include: 1. Pressure-sensitive adhesives; 2. Thermal bonding adhesives.

To properly select an adhesive, some factors to consider include: 1. Thermal exposure; 2. Chemical resistance; 3. Bonding ability of different materials.

Precautions for using FPC stiffener boards

When using reinforcement boards, it must be noted that the reinforcement should overlap the exposed cover board to relieve pressure. Additionally, when using multiple stiffeners, the same FPC stiffener thickness should be maintained.

The advantages of using FPC stiffeners cannot be overstated when we need a rigid area in the circuit to protect components or connectors. Doing so ensures that the FPC circuit does not bend and the integrity of the solder joints is protected. FR4 is commonly used as an FPC stiffener board material to reinforce specific areas of the circuit.