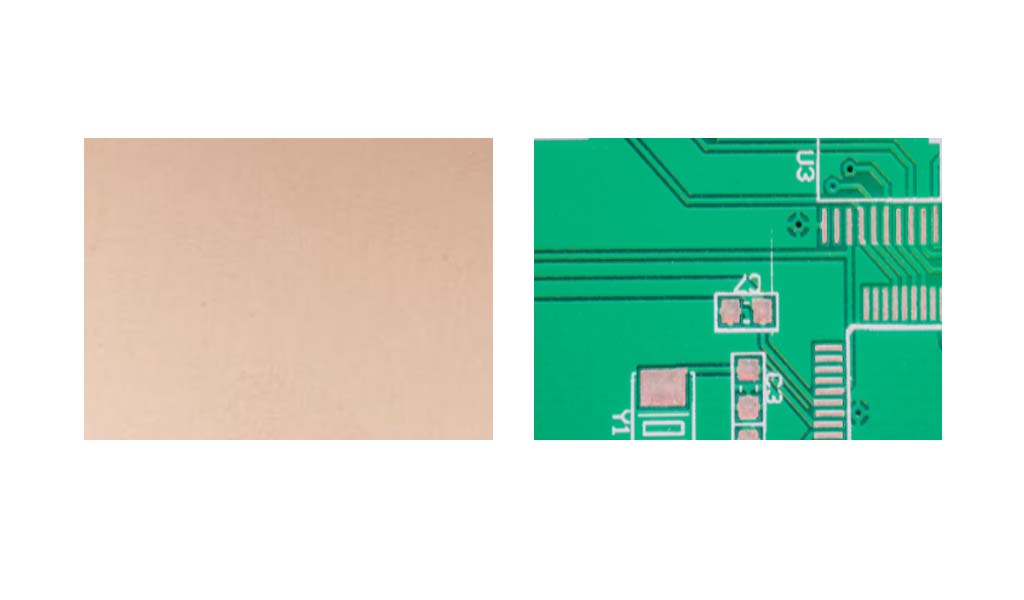

A blank PCB board, also known as a bare board or unassembled PCB board, is a circuit board without any electronic components installed. It is usually composed of an insulating material (such as glass fiber reinforced epoxy resin) and a copper foil layer, which is formed into a circuit pattern through etching, drilling and other processes to enable effective current flow when the components are placed on the circuit board. In addition, the copper coating around the blank PCB board gives the circuit board high heat resistance. They are the starting point of any PCB of a single product, and materials such as silicon can be used on them to make them rust-proof and durable.

Role:

Circuit carrying platform: The blank PCB board is the basis for the installation of electronic components. By etching the circuit pattern on the copper foil layer, electrical connections can be provided for the components.

Mechanical support: The blank pcb is responsible for accommodating the other components of the PCB, thereby providing mechanical support for the components, keeping the layout of the components neat, and ensuring that they do not loosen or shift during use.

Electrical connection: By designing a specific circuit pattern on the PCB board, components can be connected to each other through wires or solder joints to form a complete electronic circuit.

Signal transmission: The copper lines on the PCB board are used to transmit signals and currents to ensure the normal operation of the circuit.

Reduce electrical noise: By optimizing the design of the PCB board,electrical noise and interference can be reduced, and the reliability and performance of the circuit can be improved. The electronic noise of the blank board is close to the lowest, and the type of materials used in the manufacturing process determines this feature.

Blank PCB board is a vital basic component in the manufacturing process of electronic devices. Once the components are assembled, it becomes a fully functional circuit board responsible for performing various functions of the device. Designers and engineers are free to add components to the blank PCB according to their wishes because it accepts any type of modification. The flexible quality makes the blank PCB very feasible during mass production.

Blank PCB boards can be divided into many types according to their structure, number of layers and purpose. The following are the common types:

Single-Sided PCB:

Structure: Only one layer of copper foil is used for wiring, and all components are mounted on one side of the board.

Uses: Used for simple circuits and cost-sensitive applications such as toys, low-end electronics.

Advantages: Single-sided blank PCBs are easier to design and manufacture, making them the most cost-effective type of blank PCBs. In addition to being easy to design and manufacture, they are also easy to repair and suitable for low-density designs.

Double-Sided PCB:

Structure: There are two layers of copper foil, which can be routed on both sides of the PCB, and components can be mounted on both sides of the board.

Uses: Suitable for circuits of medium complexity, such as home appliances, audio equipment, etc.

Advantages: Double-sided PCBs can be used for more advanced electronic applications because they use more complex circuit systems. Finally, they utilize both size and space because both sides of the circuit board are utilized, making them more cost-effective.

Multilayer PCB:

Structure: It consists of three or more layers of copper foil, which are laminated by inner layers. The middle layer is usually used for power or ground planes, and the outer layer is used for signal transmission.

Uses: Used for complex circuits, high-performance equipment, such as computer motherboards, communication equipment, and aerospace systems.

Advantages: Simplified structure and reduced weight due to elimination of connectors that require multiple separate PCBs. The advantage of multi-layer PCBs is low production cost while maximizing the product life cycle.

Selecting the right type of PCB is key to designing and manufacturing efficient and reliable electronic products. Each blank PCB board has its own unique advantages based on its characteristics and structure, suitable for different electronic application scenarios.