1. Aluminium Oxide

Aluminium oxide substrates are the most commonly used substrate data in the electronics industry.Compared to most other oxide ceramics, it has higher strength and chemical stability in terms of mechanical, thermal and electrical performance and is available in a wide range of raw materials. It is suitable for a wide range of technologies and shapes.

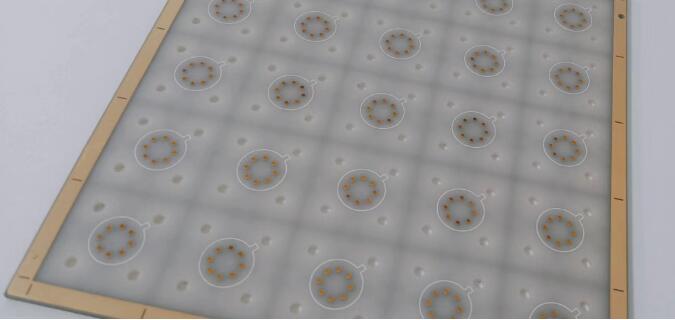

Alumina ceramic substrates

2.Beryllium oxide

It has higher thermal conductivity than metallic aluminium and is used where high thermal conductivity is required. However, the temperature drops rapidly after the temperature exceeds 300°C. Most importantly, its toxicity limits its development. Most importantly, its toxicity limits its own development. Beryllium oxide ceramics are ceramics with beryllium oxide as the main component. Mainly used as large-scale integrated circuit substrate, high-power gas laser tube, transistor heat sink shell, microwave output window and neutron decelerator and other materials.

3.Aluminium Nitride

AlN has two very important properties worth noting: a high thermal conductivity and an expansion coefficient that matches that of Si. The disadvantage is that even a very thin oxide layer on the surface will have an effect on the thermal conductivity. Only by strictly controlling the data and process can we produce aluminium nitride substrates with better consistency. Compared with Al2O3, AlN is relatively expensive. This is also a small bottleneck in its development.

4.Silicon Nitride

Rogers launched the new curamik?Series of silicon nitride (Si3N4) ceramic substrates in 2012. Because silicon nitride is mechanically stronger than other ceramics, the new curamik substrates help designers achieve longer life in harsh operating environments, as well as in HEV/EV and other renewable energy applications. The new ceramic substrates made of silicon nitride have higher flexural strength than those made with Al2O3 and AlN. The fracture toughness of Si3N4 even exceeds that of zirconia-doped ceramics.

According to the manufacturing technology,there are five common types of ceramic heat sinks at this stage: HTCC, LTCC, DBC, DPC and LAM. HTCC/LTCC are sintered and cost more.

DBC and DPC are the professional technologies that have only been developed and matured for mass production in recent years in China. DBC uses high temperature heating to combine Al2O3 and Cu boards, and the technological bottleneck is that it is not easy to solve the problem of micro-porosity between Al2O3 and Cu boards. The bottleneck is that it is not easy to solve the problem of micro-vacuum between Al2O3 and Cu plate, which makes the mass production energy and yield of the product subject to greater challenges.DPC technology uses direct copper plating technology to deposit Cu on the Al2O3 substrate. The process combines the data and thin film process technology. The product is the most commonly used ceramic heat sink in recent years. However, it requires a high level of data control and process technology integration, which makes it a relatively high technology threshold to enter the DPC industry and be able to produce stable products.LAM technology is also known as Laser Activated Metallisation technology.

1.HTCC (High-Temperature Co-fired Ceramic)

HTCC is also known as High-Temperature Co-fired Ceramic.The manufacturing process is very similar to LTCC.The main difference is that the ceramic powder of HTCC has no glass material added.Therefore, HTCC must be dried and hardened at a high temperature of 1300~1600℃ to form a raw blank.The holes are then drilled, filled and printed using screen-printing technology. Due to the high co-firing temperature, the choice of metal conductor materials is limited. The main materials are tungsten, molybdenum, manganese, etc., which have high melting points but poor electrical conductivity, and are then laminated and sintered.

2.LTCC (Low-Temperature Co-fired Ceramic)

LTCC is also known as Low-Temperature Co-fired Multi-Layer Ceramic Substrate.The technology must first inorganic alumina powder and about 30% ~ 50% of the glass data and organic binder mixed well, so that it is mixed into a mud-like paste, and then scrape the paste into a sheet with a scraper, and then after a drying process will be formed into a sheet of thin slurry embryo, and then according to the design of each layer of the drilling guide through the holes, as the signal transmission of each layer, the internal circuit of the LTCC screen printing technology, respectively, used for filling on the embryo.The internal circuits of LTCC are screen printed using screen printing technology, which is used to fill the holes and print the circuits on the blanks respectively. The internal electrodes and external electrodes can be silver, copper, gold and other metals, and finally the layers are pressed and placed in a sintering furnace at 850~900°C to complete the sintering process.

3.DBC (Direct Bonded Copper)

Direct Bonded Copper (DBC) is a technology that uses an oxygenated eutectic solution of copper to directly bond copper to ceramics.The basic principle is to introduce an appropriate amount of oxygen between copper and ceramic before or during the bonding process, and in the range of 1065℃~1083℃, copper and oxygen form a Cu-O eutectic solution.DBC Technology uses this eutectic solution to form CuAlO2 or CuAl2O4 by chemical reaction with the ceramic substrate on one hand, and on the other hand, it impregnates the copper foil to bond the ceramic substrate with the copper plate.

ipcb is a precision circuit board manufacturer, and has professional advantages in circuit boards, precision circuit,high-frequency circuit boards, high-speed circuit boards, chip carrier boards, IC substrates, semiconductor test boards, ceramic boards, and HDI circuit boards.