Proper thermal management in RF/microwave design begins with careful selection of electronic materials, and printed circuit board (PCB) are the most important of these materials. In high-power, high-frequency circuits such as power amplifiers, heat may accumulate around the active components in the amplifier. In order to prevent damage to device nodes, nearby circuit components, or even PCB materials, the system must correctly dissipate heat from active devices and safely dissipate it through device packaging, circuit grounding, heat sinks, equipment chassis, and ambient air. The selection of PCB materials has a significant impact on the overall thermal management of high-power RF/microwave design.

The power processing capability of circuit materials is related to their ability to control temperature rise, which is a function of external power and dissipated power. For most electronic components, an increase in operating temperature will shorten their lifespan and often reduce their electrical performance. Whether it is a high ambient temperature or an increase in the temperature of the circuit and its components caused by high-power operation, the result will be damage and performance degradation at high temperatures. Keeping the circuit at a lower temperature based on the amount of power that must be dissipated typically ensures higher reliability.

What happens to PCB at high temperatures? Like most materials, PCB undergo thermal expansion and contraction with temperature changes - as the temperature rises, PCB expand along three axes (length, width, and thickness). The degree of expansion caused by temperature changes can be characterized by the coefficient of thermal expansion (CTE) of PCB materials. Because PCB is typically formed from composite copper (used to form transmission lines and ground planes) dielectric, the linear CTE of this material in the x and y directions is typically designed to match the CTE of copper (approximately 17ppm/℃). Through this method, these materials will expand and contract together with temperature changes, thereby minimizing the stress at the connection between the two materials to the greatest extent possible.

The CTE of dielectric materials along the z-axis (thickness) is typically designed to be a lower value in order to minimize size changes with temperature and maintain the integrity of plated through holes (PTH). PTH provides the necessary path from the top to the bottom of the circuit board for grounding and interconnection of multi-layer circuit board.

In addition to mechanical changes, temperature can also affect the electrical performance of PCB. For example, the relative dielectric constant of PCB laminates is a function of temperature, defined by the thermal coefficient of the dielectric constant. This parameter describes the change in dielectric constant (usually measured in ppm/℃). Due to the fact that the impedance of high-frequency transmission lines depends not only on the thickness of the substrate material, but also on its dielectric constant, changes in the z-axis CTE and dielectric constant as a function of temperature can significantly affect the impedance of microstrip and strip transmission lines made on this material.

Of course, microwave circuits rely on closely matched impedance between components and circuit nodes to minimize reflections that may cause signal loss and phase distortion. In power amplifier circuits, impedance matching circuits are used to convert the typical low impedance of power transistors to the typical 50 Ω characteristic impedance of RF/microwave circuits or systems. The changes in transmission line impedance caused by temperature effects of high-power signals may alter the frequency response of high-frequency amplifiers. Therefore, careful selection of PCB laminates should be made to minimize these effects as much as possible.

There are many other parameters that are also useful when choosing PCB materials that help minimize heat generation at high power levels and frequencies. At a certain temperature point, certain materials will change their state, and this temperature is one of the parameters - known as the liquid glass transition temperature or glass transition temperature (Tg). For example, it can indicate the temperature at which significant changes will occur in the CTE characteristics of a material (Figure 1). Due to significant changes in the CTE of materials, their mechanical and electrical properties become unstable when the operating temperature exceeds Tg. Therefore, except for brief processing procedures (such as reflow soldering, where the material is required to be at a higher temperature), the operating temperature should always be maintained below this temperature.

Another key parameter related to temperature is the maximum operating temperature (MOT) of the PCB. MOT is a rating defined by Underwriters Laboratories (UL) for a single PCB structure produced using specific PCB materials at a particular circuit fabrication site. MOT is the highest temperature at which a PCB can operate normally for any duration without significantly reducing the critical performance attributes of the circuit. If the circuit operates at temperatures higher than MOT for a prolonged period of time, reliability risks will be worth considering. The MOT rating means that it provides a safe high-temperature indication for the PCB, although it does not include the impact of high input power levels on the PCB.

The thermal conductivity of PCB materials can be used as a relative indicator of the heat dissipation efficiency of laminated board. This parameter essentially describes the thermal conductivity of PCB materials, measured in watts per meter of material per Kelvin temperature. Similar to conductivity and electron flow in materials, thermal conductivity is used to estimate the energy loss rate of heat passing through a given material. The reciprocal of thermal conductivity is thermal resistance, or the ability of a material to prevent heat flow.

The thermal conductivity depends on various properties of the material, such as its molecular structure. For example, glass is a poor thermal conductor with an extremely low thermal conductivity of 1.1W/(m-K). On the other hand, copper has a low impedance to heat flow and a very high thermal conductivity of 401W/(m-K). Due to the particularly low thermal conductivity of PCB dielectric materials (the thermal conductivity of high TgFR-4 circuit materials is generally around 0.24 W/(m-K)), heat can easily accumulate on the wires of high-power PCB (which are usually made of copper with extremely low thermal resistance). But choosing PCB materials with higher thermal conductivity allows the circuit to operate at higher power levels.

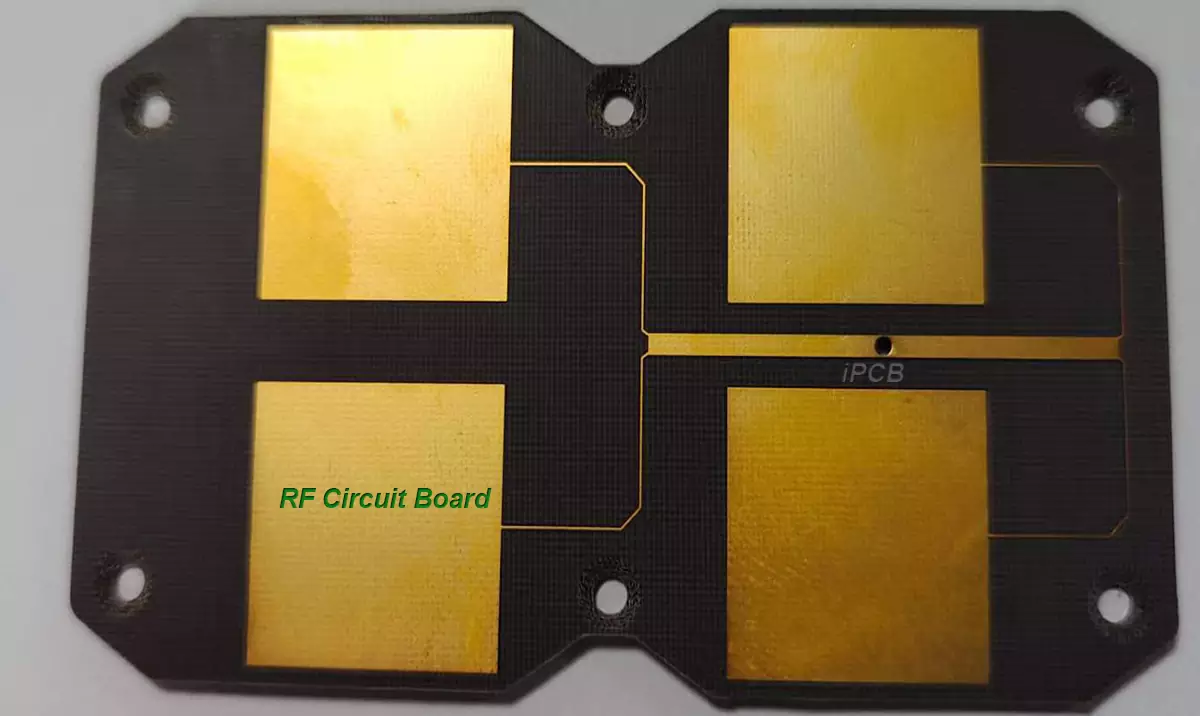

RF Circuit Board

Rogers RT/duroid 6035HTC has much higher thermal conductivity than FR-4 and even several low loss high-frequency laminates. This material consists of ceramic filled PTFE composite dielectric and standard or reverse treated electrolytic (ED) copper foil. This material is widely used for efficient thermal management in hundreds of watts of power microwave amplifiers due to its high thermal conductivity. On the z-axis, its relative dielectric constant at 10GHz is 3.50, and its tolerance across the entire circuit board remains within ± 0.05, thereby maintaining consistent impedance of the transmission line. The CTE of the x and y axes is 19ppm/℃, which is close to matching the CTE of copper.

Of course, in circuit design, proper thermal management is not simply about selecting circuit laminates with the best thermal properties. There are many other factors that can affect the temperature of a circuit operating at a given power level and frequency. For example, circuit materials are characterized by dissipation factors, which are losses caused by dielectric materials. There are also losses through conductive transmission lines (such as microstrip lines or strip line circuits), and higher insertion losses will result in the transmission line generating more heat at higher power levels. The roughness of copper conductors on PCB can lead to an increase in insertion loss, especially at higher frequencies.

In addition, the selection of the dielectric constant of PCB materials will determine the size and density of RF/microwave circuits, as the size of microwave transmission line structures depends on the wavelength of the signal to be processed. When the relative dielectric constant is large, the size of the transmission line required to achieve a given impedance will be smaller, and the power processing capability of the PCB will be limited by the width and insertion loss of the wires, as well as the ground plane spacing. For example, for an amplifier circuit, selecting PCB materials with smaller relative permittivity can make the transmission line wider for a given impedance, thereby improving heat flux. Using PCB materials with relatively high dielectric constants will result in finer transmission line sizes and denser spacing in circuits, which may form hotspots in high-power circuits. In addition, selecting materials with low dissipation factor can help minimize the insertion loss of transmission lines and optimize the gain of amplifier circuits to the greatest extent possible.

All PCB materials experience temperature rise when handling high RF power levels. But different materials, even different copper layers, can affect the power processing capability of the circuit. If conservative MOT parameters are considered to ensure a longer working life for PCB laminates and high-frequency Circuit board designs, then low loss, high thermal conductivity, and stable mechanical temperature characteristics should be taken into account when selecting materials.