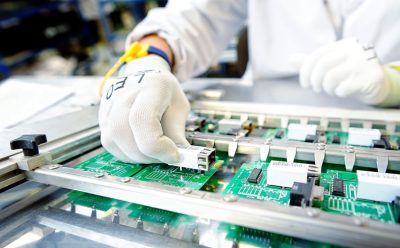

iPCB performs a series of quality checks on through-hole PCB assembly. The first step is to check that components are correctly placed and free of solder bridges.This is done using a microscope.

The second step is to check that all components are correctly soldered. This is done using an optical inspection machine

The third step is to check for missing and/or extra components. This is done using an X-ray machine and a microscope, respectively.

Through-hole PCB assembly is the most common type of surface mount assembly. Through-hole boards have holes for soldering components. The holes are typically arranged in rows and columns.

Through-hole boards can be single-sided or double-sided. Single-sided boards contain only one layer, onto which all components are soldered. Double-sided boards have two layers, one for the top side and the other for the bottom side.

It's not necessary to solder all components on a double-sided board. You can solder only some to reduce the cost and weight of your product.

We offer fast-turnaround through-hole PCB assembly services using high-precision equipment and advanced technology, providing our global customers with high-quality products and services at competitive prices!

iPCB's top-quality through-hole PCB assembly is the best choice for professional electronics manufacturers. Our high-quality lead designs offer many features that make them ideal for various through-hole PCB types, including:

Conductive layers made of pure copper.

A large number of plated holes (over 100) ensure the conductive layer won't break or tear easily during assembly.

Anti-static coating on both sides of the leads prevents damage from static electricity and improves reliability.

Through-hole Assembly Quality Standards

When providing through-hole PCB assembly services, we adhere to IPC quality standards. Understanding common defects in through-hole PCBs and how to avoid them is crucial.

Solder joint quality impacts the overall quality of through-hole PCB construction. Solder joints are crucial for manufacturing products that connect everything together, especially the circuit board and its components.

Solder joint defects include issues like inaccurate component placement, breakage, shorts, protruding leads, and corrosion.

Advantages of Through-Hole Assembly:

Why Try Through-Hole Assembly for PCB Manufacturing?

1. Easier Prototyping

Through-hole components are easily replaceable, making them ideal for PCB prototyping and testing.

2. High Heat Resistance

THT bonds offer high heat resistance, making them a top choice for aerospace and military applications.

3. Better Power Handling Capacity

Soldering through-hole components creates a strong bond between the circuit board and the component. This makes it ideal for larger assemblies subject to the following:

4. Stronger Physical Connection

Whether you are an electrical engineer, product designer, system integrator, or manufacturer seeking flexible PCB assembly, we are your expert through-hole assembly provider. With our 24/7 sales and technical support teams, a two-hour quick response service, and excellent after-sales service, we are your premium through-hole assembly partner.

The key differences between through-hole and surface-mount components are:

Through-Hole vs. Surface-Mount PCB Assembly

1. Drilling holes and soldering leads on the opposite side of the board means only one side of the board can be used for through-hole mounting.

This minimizes the space available for mounting components. However, with surface-mount mounting (SMT), both sides of the board can be used because no holes are drilled. This makes SMT ideal for manufacturing circuit boards with many components. Therefore, it is used to create smaller, lighter designs that are more robust.

2. The components used in SMT are typically much smaller, allowing multiple components to be mounted on a relatively small board.

This also increases functionality, making SMT a better choice for producing more compact, portable, and efficient circuits.

3. In SMT, boards can accommodate a higher pin count than in THM; therefore, circuit boards can have higher component lead counts than THM.

4. Production volumes with SMT can be very high.

This is because the process does not involve drilling holes, as with THM, which is often difficult and time-consuming. This high-volume production allows for economies of scale; therefore, the per-unit production cost is significantly lower, making it a more profitable option.

5. SMT requires a higher capital investment than THM for machine setup and production processes.

Therefore, it is only suitable for large-scale production where economies of scale help overcome these higher costs.

6. Using SMT requires a higher level of skill and technology than THM. The need for more advanced technology also comes at a higher price.

7. Despite SMT's seemingly overwhelming advantages, through-hole assembly is still primarily used for testing and prototyping applications.

This is because manual adjustments are always required at this stage

Through-hole PCB Assembly Capabilities

We are fully capable of providing the following through-hole PCB assembly services:

1) Manual and automated component placement

2) Dual-wave soldering

3) RoHS-compliant soldering using tin-lead solder

4) Functional testing

How much does through-hole PCB assembly cost? The cost of producing through-hole PCB assemblies depends on a variety of factors, including the type of through-hole PCB part, order quantity, specialized processes, and lead time.

Most importantly, we have a team of experienced professionals specializing in manual component placement, automated axial and radial component insertion, and automated dual-wave soldering.through hole pcb assembly

In addition to through-hole PCB assembly, we also offer other value-added services such as conformal coating, labeling, surface treatment, and complete PCB packaging.