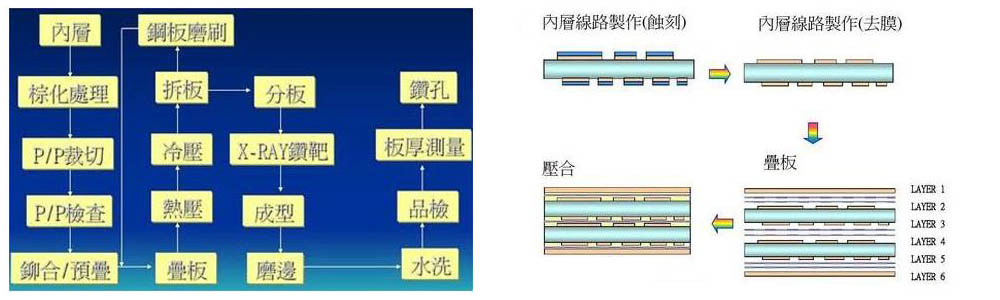

Many customers receive multi-layer circuit boards and find that they are warped, delaminated, or even have serious quality problems such as broken open circuits on the inner layers. A big reason for this is that PCB manufacturers have problems with the PCB lamination process.

Some PCB manufacturers do not have their own circuit board lamination process line, circuit board lamination process can only be outsourced to his factory OEM, and many OEM factories in the equipment, process and there are many defects, resulting in the quality of the circuit board lamination process is not controllable.

For example:

PCB manufacturers are not equipped with hot melt machine, X-RAY drilling target machine, through the riveting process circuit board lamination process, the precision of inter-layer alignment affected by the tolerance of the rivet holes, circuit board lamination process will lead to the deformation of the rivets, resulting in inter-layer bias bit.

(This forces the requirement of a larger hole-to-line spacing for a high precision board to have a lower scrap rate.)

PCB manufacturers of circuit board laminating machine failure rate is high, unexpected events lead to production inefficiency, unable to deliver goods on time, affecting the delivery schedule

This PCB manufacturers need to have some requirements:

1. Deep manufacturing experience

With professional Japanese circuit board lamination process machine, laminating machine, one of the oldest manufacturers, founded in 1933, so far in the field of presses with deep manufacturing experience and core technology, and has been Japan and Asia, Europe and the United States and a large number of large-scale PCB enterprise verification and recognition, in 1942 on the research and development of Japan's first plywood with a hot press, in 1985 developed a multi-layer printed circuit boards with a vacuum press! )

2.High Reliability & Stability

Customers have always been concerned about the reliability and stability of the quality of Huaqiu is also extremely important.

Circuit Board Lamination

The precision program of the specially tuned dedicated controller (VISTAC-ⅡC) accurately controls the heating of the hot plate, the thermal cycling of the cooling, and the control of the liquid pressure and temperature. Through the operation of the cold press, the stress can be effectively eliminated to carry out each circuit board lamination process with high efficiency and quality.

Moreover, the machine itself has excellent processing precision, coupled with reliability and low failure rate, together with high hardness,flat imported steel plate (one of the core accessories for circuit board lamination process), SangYi's high-quality PP sheet (bonding sheet) and supporting professional equipment, it can effectively avoid process defects and improve the quality of circuit board lamination process.

For example:

Avoiding excessive adhesive flow, uneven adhesive content of the inner layers leading to warpage, delamination and other process defects, fully guaranteeing the high yield of the multilayer board lamination process!

Extremely low failure rate and precise automation control can reduce production risk, maintain efficient and stable production, and save time for customers!

Ultimately, the quality requirements of customers are met: high reliability + high stability.

Circuit Board Lamination

MVLP vacuum and pressurization process

The vacuum chamber consists of upper and lower hot plates with heaters inside.

When the product is loaded into the hot plate, the hot plate is closed (forming a chamber) and the interior is in a vacuum state.

After a set period of time, the air cushion is supplied with compressed air and expands to press the product against the hot plate.

Through this compression force and heat, the circuit board lamination process is carried out.

What other factors affect the yield of the circuit board lamination process?

1. The quality of the laminate:

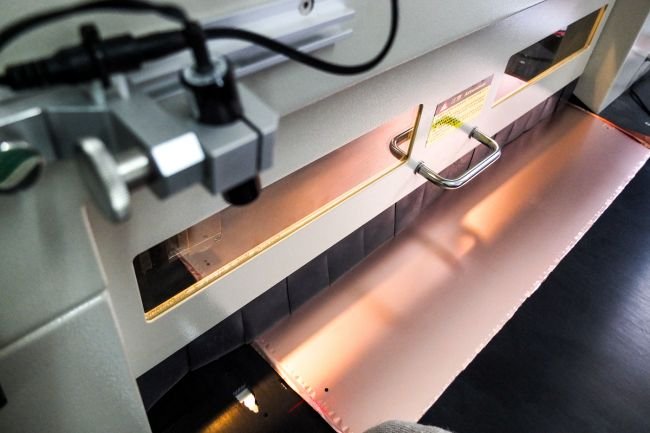

The steel plate is one of the accessories of the circuit board lamination process, such as insufficient hardness, poor flatness, etc. will cause damage to the process.

For example:

Circuit board lamination process thickness tolerance precision is not high, the board surface has indentation.

We always choose German imported mirror steel plate: high hardness, high hardness, high homogeneity, high toughness, heat resistance, pressure resistance, wear resistance, can resist thermal expansion and contraction or in the transportation process of collision, friction caused by deformation and scratch, even if repeated circuit board lamination process, the steel plate can still maintain a high degree of flatness.

2.High precision X-RAY drilling and melting machine:

X-RAY drilling target machine is used for interlayer alignment after circuit board lamination process, the principle is that after multi-layer board lamination process, through X-Ray projection pads, to determine the accuracy of the inner layers and to set the bit holes (drilling target).

Thermal fusion machine through the high temperature, pressure will be PP and core board bonding fixed (that is, commonly known as “fusion”), and ordinary riveting process circuit board lamination process, the accuracy of inter-layer alignment by the rivet hole tolerance, circuit board lamination process impact will lead to deformation of rivets, resulting in inter-layer bias bit.

Some PCB factories do not use x-ray and heat fusion machine to save cost, which leads to the frequent occurrence of layer deviation problem.

We are equipped with the ADT series target drilling machine produced by Taiwan's professional X-RAY manufacturer “AbleTek”, which has high accuracy and effectively ensures the relative position of each through-hole in the inner layer board to avoid the phenomenon of layer deviation.

3.PP bonding sheet: PP sheet is a sheet material, in which the resin is in the B-stage, under the action of temperature and pressure, it has the mobility and can quickly cure and complete the bonding process, and form an insulating layer together with the carrier. The quality of the PP sheet also affects the reliability and stability of the multilayer board.

We choose SangYi A-grade laminates with SangYi PP sheets to ensure the high reliability of our multilayer boards.

Circuit Board Lamination

Due to customer's lack of understanding of circuit board lamination process, the above is to understand the lamination process of multi-layer circuit boards.